A kind of nanoscale pure waterborne metal anticorrosion coating and its preparation method and application

A metal anti-corrosion, nano-scale technology, applied in the direction of anti-corrosion coatings, coatings, etc., can solve the problems of poor anti-corrosion performance, slow drying speed, high VOC content, etc., to achieve shortened aging time, fast drying speed, excellent neutral salt resistance The effect of fog performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] Embodiment 1, the preparation of nanoscale pure water-based metal anticorrosion coating

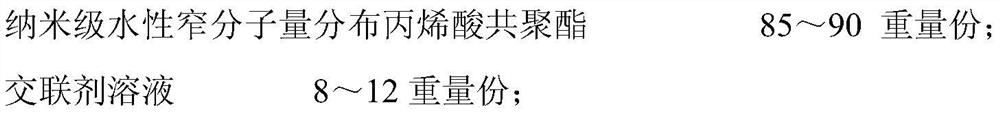

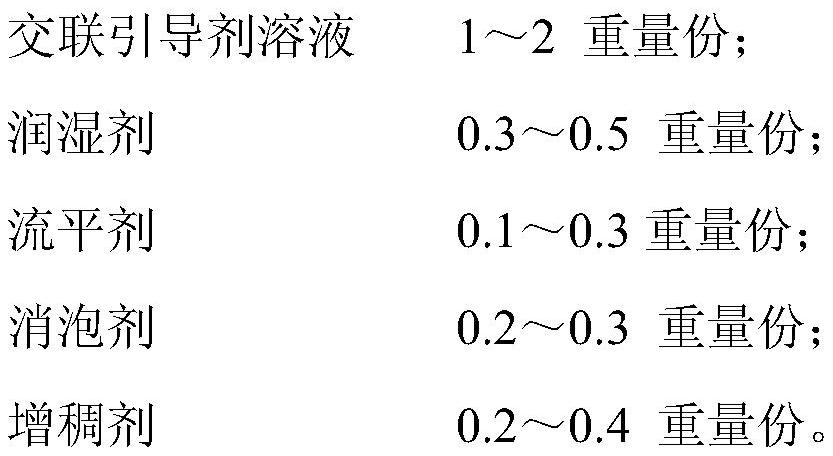

[0064] The present embodiment adopts formula 1. The preparation of nanoscale pure water-based metal anticorrosion coating comprises the following steps:

[0065] (1), the nano-scale water-based narrow molecular weight distribution acrylic copolyester NNWBR TM Add MS-01 into the batching kettle, start stirring, control the stirring speed at 200RPM, then add the cross-linking agent solution of the formula amount into the batching kettle within 20 minutes, stir for 25 minutes after the addition is complete to fully mix, and then add the formula amount The cross-linking guide agent solution was added to the batching kettle within 20 minutes, and stirred for 8 minutes after the addition was completed to fully mix;

[0066] (2) Add the formula amount of wetting agent, leveling agent and defoamer in sequence, and stir for 35 minutes after adding to fully mix;

[0067] (3) Use an approp...

Embodiment 2

[0068] Embodiment 2, the preparation of nanoscale pure water-based metal anticorrosion coating

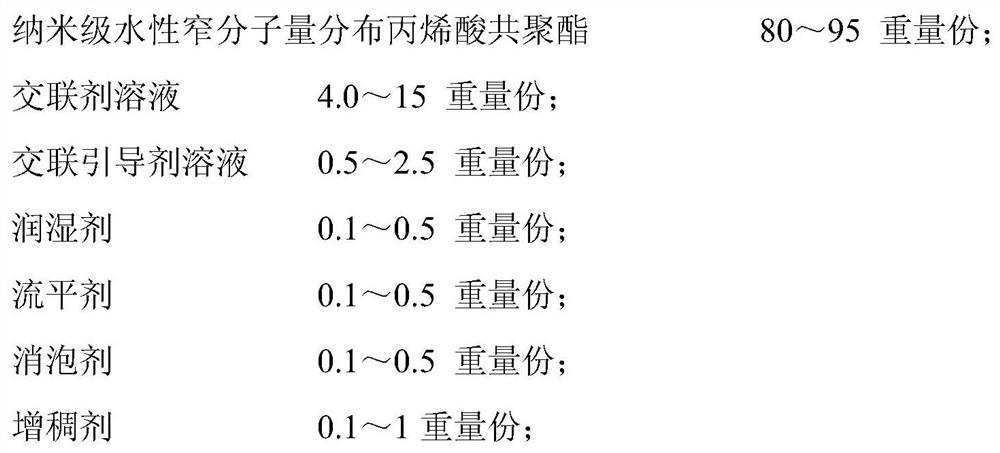

[0069] This embodiment adopts recipe 2. The preparation of nanoscale pure water-based metal anticorrosion coating comprises the following steps:

[0070] (1), the nano-scale water-based narrow molecular weight distribution acrylic copolyester NNWBR TM Add MS-01 to the batching kettle, start stirring, control the dispersion speed at 300RPM, then add the cross-linking agent solution of the formula amount into the batching kettle within 30 minutes, stir for 15 minutes after the addition is complete to fully mix, and then put the formula amount The cross-linking guide agent solution was added to the batching tank within 30 minutes, and stirred for 5 minutes after the addition was completed to fully mix;

[0071] (2) Add the formula amount of wetting agent, leveling agent and defoamer in sequence, and stir for 30 minutes after adding to fully mix;

[0072] (3) Use an appropriate amou...

Embodiment 3

[0073] Embodiment 3, the preparation of nanoscale pure water-based metal anticorrosion coating

[0074] Present embodiment adopts formula 3, the preparation of nanoscale pure water-based metal anticorrosion coating, comprises the following steps:

[0075] (1), the nano-scale water-based narrow molecular weight distribution acrylic copolyester NNWBR TM Add MS-01 into the batching kettle, start stirring, control the dispersion speed at 150RPM, then add the crosslinking agent solution of the formula amount into the batching kettle within 10 minutes, stir for 30 minutes after the addition is complete to fully mix, and then put the formula amount The cross-linking guide agent solution is added to the batching tank within 10 minutes, and stirred for 10 minutes after the addition is completed to fully mix;

[0076] (2) Add the formula amount of wetting agent, leveling agent and defoamer in sequence, and stir for 45 minutes after adding to fully mix;

[0077] (3) Use an appropriate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com