Preparation method and application of internal-external dual cross-linked core-shell structured acrylic acid emulsion

A technology of acrylic emulsion and core-shell structure, applied in the field of polymer material synthesis, can solve the problems of difficulty in solving hardness and minimum film-forming temperature, development and application limitations, loss of water-based paint, etc., to achieve VOC emission and improve densification the effect of lowering the glass transition temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

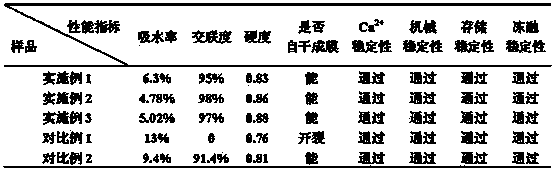

Examples

Embodiment 1

[0036] (1) Preparation of seed monomer: Mix 4 parts by mass of butyl acrylate, 2 parts by mass of methyl methacrylate, 0.1 part by mass of methacrylic acid, and 0.18 parts by mass of trimethylolpropane trimethacrylate to obtain a seed monomer body;

[0037] (2) Preparation of seed emulsion: Take 1.28 parts by mass of compound emulsifier, 0.06 parts by mass of potassium persulfate, dissolve in 60 parts by mass of deionized water, stir well and add to Put the funnel in a four-necked flask and place it in a constant temperature water bath, heat it to 80°C at a speed of 300 rpm, then reduce the speed to 200rmp, and pass the seed monomer through a constant pressure dropping funnel within 10 minutes Add it dropwise into a four-necked flask, and keep it warm for 15 minutes until there is no obvious reflux on the bottle wall to obtain a seed emulsion; the composite emulsifier is composed of 0.96 parts by mass of DSB and 0.32 parts by mass of OP-10;

[0038](3) Preparation of core lay...

Embodiment 2

[0041] (1) Preparation of seed monomers: Mix 8 parts by mass of butyl acrylate, 5.6 parts by mass of methyl methacrylate, 0.5 parts by mass of methacrylic acid, and 0.75 parts by mass of ethylene glycol dimethacrylate to obtain seed monomers;

[0042] (2) Preparation of seed emulsion: Take 1.7 parts by mass of compound emulsifier, 0.16 parts by mass of ammonium persulfate, dissolve in 80 parts by mass of deionized water, stir well and add to funnel in a four-necked flask, and placed in a constant temperature water bath, heated to 85 °C at a speed of 400 rpm, then reduced to 160 rpm, and the seed monomer was passed through a constant pressure dropping funnel in the Drop it into a four-neck flask within 15 minutes, and keep it warm for 20 minutes until there is no obvious reflux on the bottle wall to obtain a seed emulsion; the composite emulsifier consists of 0.85 parts by mass of DSB and 0.85 parts by mass of OP-10;

[0043] (3) Preparation of core layer emulsion: Take 72 part...

Embodiment 3

[0046] (1) Preparation of seed monomers: 6.15 parts by mass of butyl acrylate, 2.76 parts by mass of methyl methacrylate, 0.24 parts by mass of methacrylic acid, and 0.4 parts by mass of dipentaerythritol acrylate were uniformly mixed to obtain seed monomers;

[0047] (2) Preparation of seed emulsion: Take 1.5 parts by mass of compound emulsifier, 0.09 parts by mass of ammonium persulfate, dissolve in 80 parts by mass of deionized water, stir well and add to funnel in a four-necked flask, and placed in a constant temperature water bath, heated to 75°C at a speed of 400 rpm, then reduced to 220 rpm, and the seed monomer passed through a constant pressure dropping funnel in Drop it into a four-neck flask within 12 minutes, and keep it warm for 15 minutes until the bottle wall has no obvious reflux to obtain a seed emulsion; the composite emulsifier consists of 0.375 parts by mass of DSB and 1.125 parts by mass of OP-10;

[0048] (3) Preparation of core layer emulsion: Take 55.35...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com