Bottom circuit board full-component microwave fast digestion and precious metal ionic liquid extracting method

A precious metal ion, waste circuit board technology, applied in the direction of improving process efficiency, to avoid heat loss, strong selectivity, and non-volatile effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

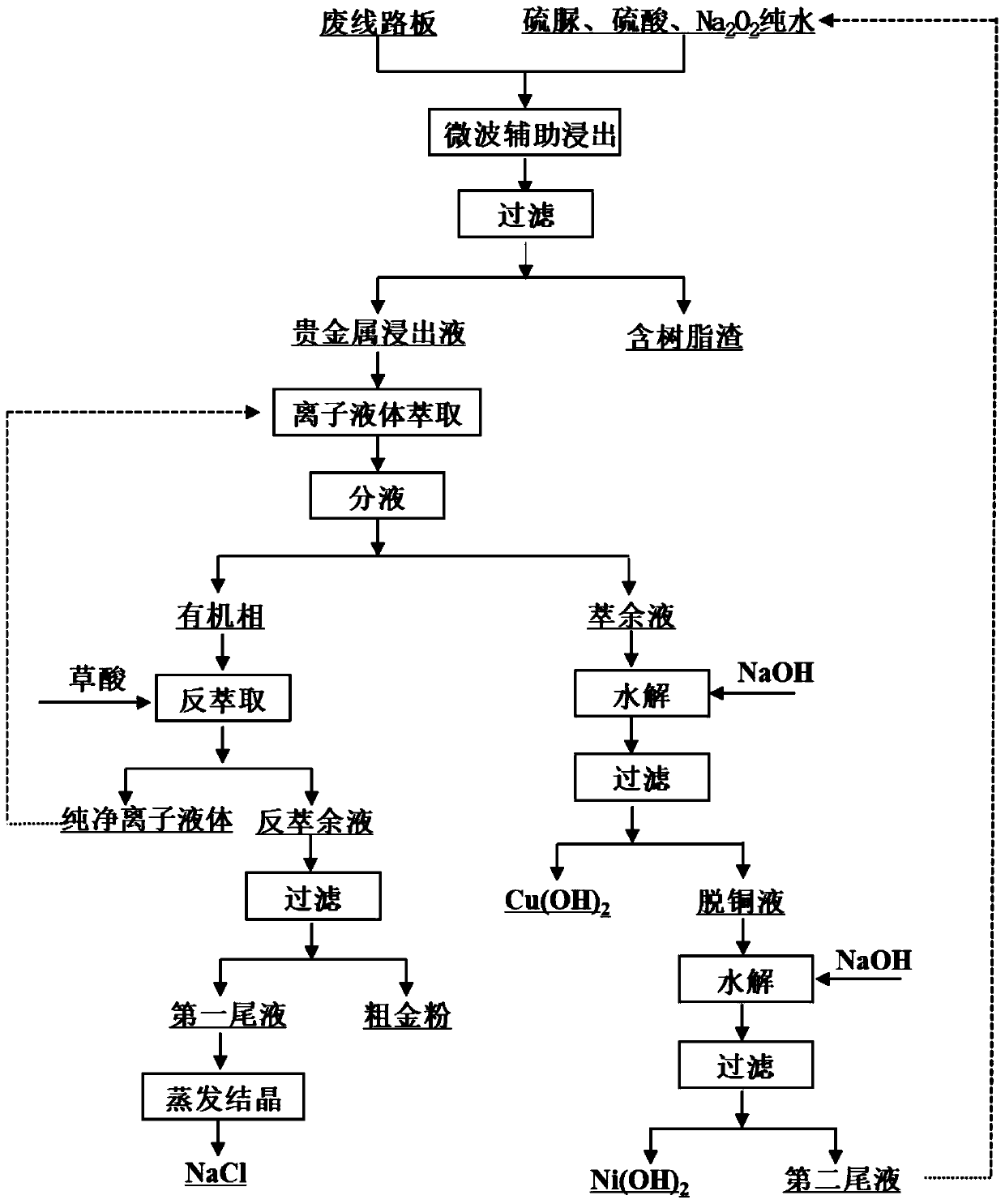

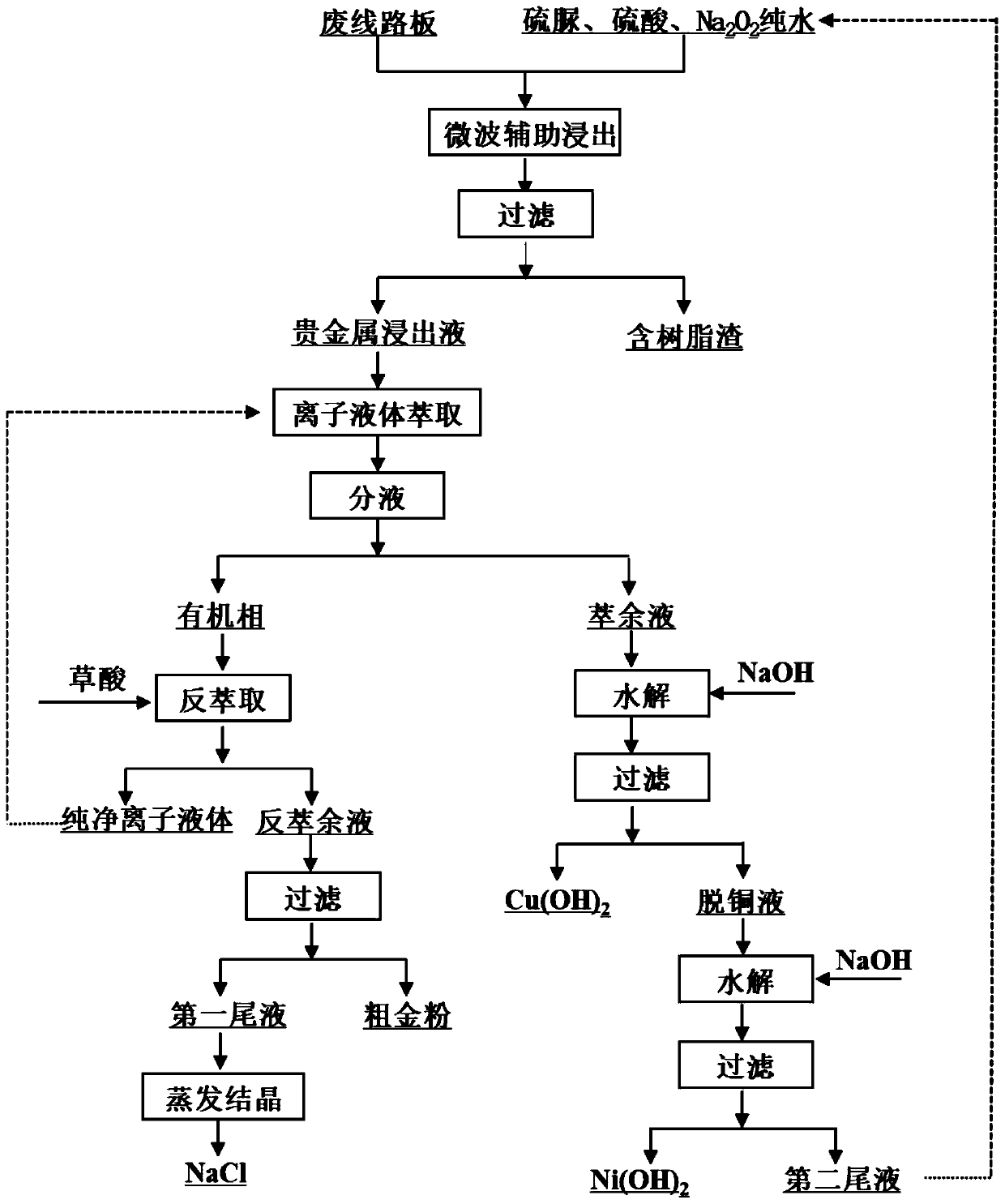

Method used

Image

Examples

example 1

[0019] Cut the waste circuit board into small pieces, each weighing 0.1g, to obtain the pretreated waste circuit board; configure a precious metal extraction solution in a beaker, the concentration is thiourea: 1.5mol / L, sulfuric acid 1.5mol / L, over Sodium oxide 2mol / L; put the pretreatment circuit board in the digestion tank, pour the leaching solution into the digestion tank at the same time, set the microwave digestion instrument to heat up to 185°C for 1h, holding time for 20min, cooling time for 15min, and cool to 60°C, after cooling, filter to obtain precious metal leaching solution and resin-containing waste residue; put the precious metal leaching solution in the extraction tank, add imidazole ionic liquid [BMIM][NTF2] according to the volume ratio of ionic liquid to precious metal leaching solution 1:1, and stir thoroughly After 5 minutes, the oil and liquid phases were fully mixed to obtain the oil and liquid mixed phase. Add oxalic acid solution to the organic phase...

example 2

[0021] Cut the waste circuit board into small pieces, each weighing 0.15g, to obtain the pretreated waste circuit board; configure a precious metal extraction solution in a beaker, the concentration is thiourea: 2mol / L, sulfuric acid 1.8mol / L, peroxide Sodium 1.5mol / L; put the pretreatment circuit board in the digestion tank, pour the extract solution into the digestion tank at the same time, set the microwave digestion instrument to heat up to 180°C for 1.2h, holding time 20min, cooling time 25min, cooling to 60°C, after the cooling is completed, filter to obtain the precious metal leachate and resin-containing waste residue; place the precious metal leachate in the extraction tank, add imidazole ionic liquid [BMIM][NTF2] according to the volume ratio of the ionic liquid to the precious metal leachate 1:2, fully Stir for 8 minutes to fully mix the oil and liquid phases to obtain the oil and liquid mixed phase. Add oxalic acid solution to the organic phase at a volume ratio of...

example 3

[0023]Cut the waste circuit board into small pieces, each weighing 0.18g, to obtain the pretreated waste circuit board; configure a precious metal extraction solution in a beaker, the concentration is thiourea: 3.5mol / L, sulfuric acid 2mol / L, peroxide Sodium 2.5mol / L; put the pretreatment circuit board in the digestion tank, pour the extract solution into the digestion tank at the same time, set the microwave digestion instrument to heat up to 190°C for 1.5h, holding time 20min, cooling time 20min, cooling to 60°C, after the cooling is completed, filter to obtain precious metal leachate and resin-containing waste residue; place the precious metal leachate in an extraction tank, add imidazole ionic liquid [BMIM][NTF2] according to the volume ratio of ionic liquid to precious metal leachate 1:3, fully Stir for 12 minutes to fully mix the oil and liquid phases to obtain the oil and liquid mixed phase. Add oxalic acid solution to the organic phase according to the volume ratio of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com