Method for preparing precise liquid medicine filtering membrane through local coating and precise liquid medicine filtering membrane

A technology of liquid medicine and filter membrane, applied in the field of bacteria and virus filtration and particles, to achieve high structural strength, reduce flow resistance, and meet the requirements of ultrafiltration filtration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

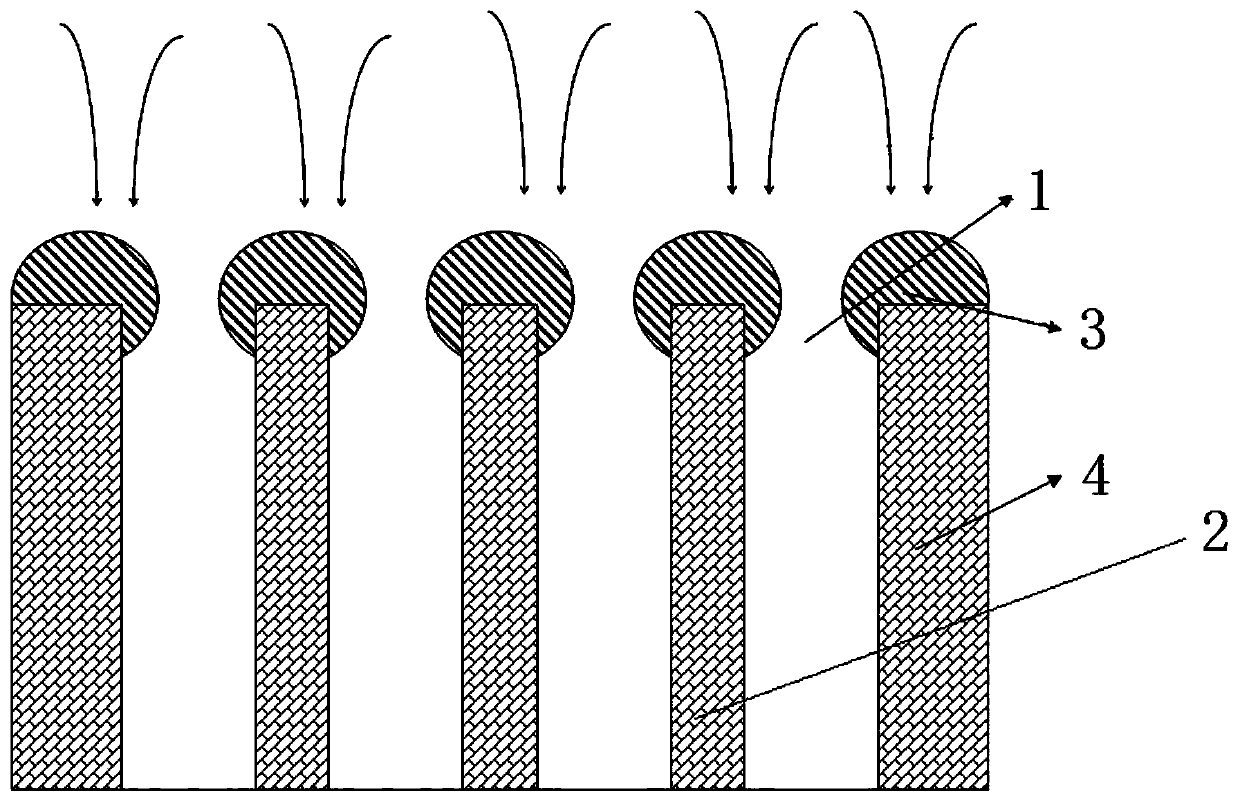

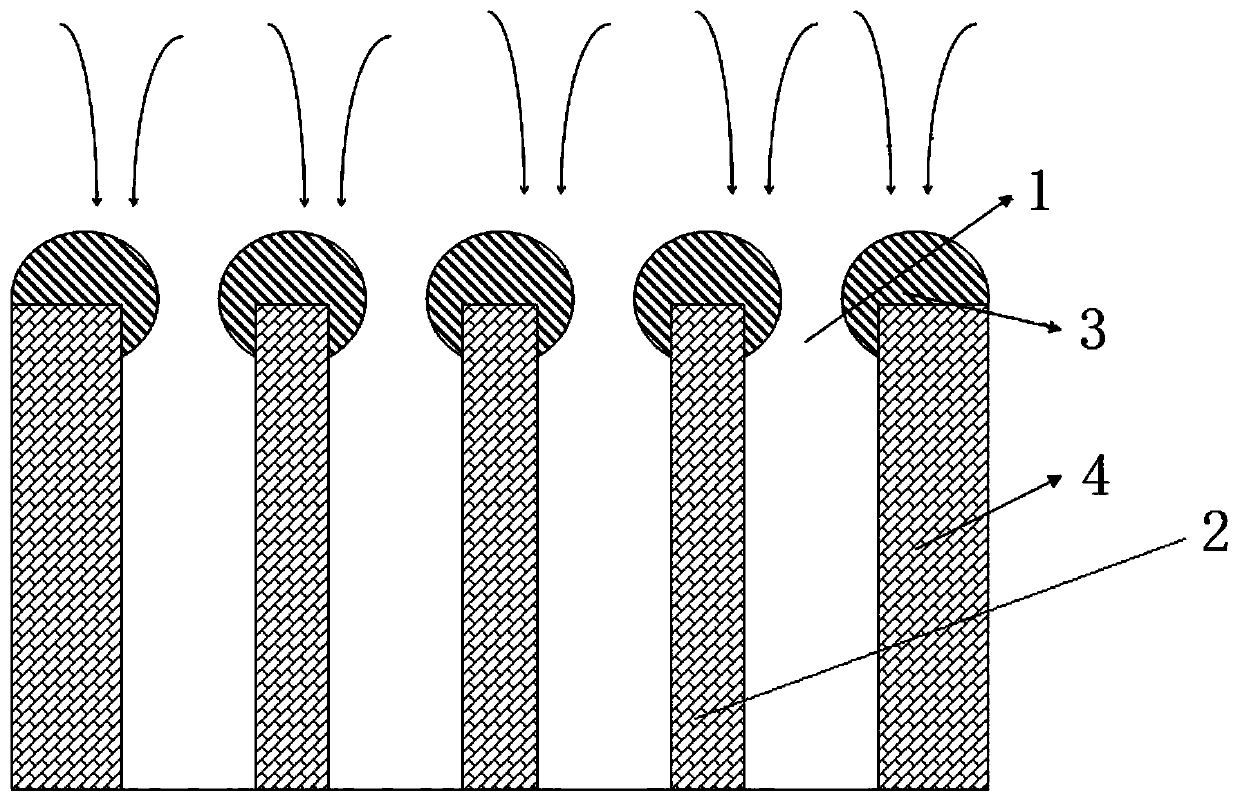

[0049] The porous anodic aluminum oxide AAO filter membrane with the original filter hole diameter of 250 nanometers, through the method of the present invention, the coating body 4 that is converted into a 100 nanometer filter hole is a precise medicinal solution filter membrane of aluminum oxide, specifically comprising the following steps:

[0050] (1) Select a porous anodic aluminum oxide AAO filter membrane with a pore size of 250 nanometers as the sample, clean and dry the sample;

[0051] (2) The sample is put into the electron beam evaporation coating equipment. The voltage of the electron gun is 5kV, and the target material is made of metal aluminum;

[0052] (3) According to the requirements of shrinkage cavity of the filter membrane, a 1-4 micron thick metal coating is deposited on the surface of the filter membrane until the pore diameter at the top of the filter hole is reduced to 100 nanometers;

[0053] (4) After the electron beam evaporation coating is complet...

Embodiment 2

[0055] The porous anodic aluminum oxide AAO filter membrane with the original filter hole diameter of 90 nanometers is converted into a precision medicinal solution filter membrane with 50 nanometer filter holes and the coating body 4 is silicon oxide by the method of the present invention, comprising the following steps:

[0056] (1) Select a porous anodic aluminum oxide AAO filter membrane with a pore size of 50 nanometers as the sample, clean and dry the sample;

[0057] (2) The sample is put into the plasma enhanced chemical strong deposition PECVD equipment.

[0058] (3) According to the requirements of shrinkage of the filter membrane, deposit 1-4 micron thick silicon oxide on the surface of the filter membrane until the pore diameter at the top of the filter hole is reduced to 50 nanometers.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com