Decorative insulation board with self-cleaning function and preparation method thereof

A thermal insulation board and self-cleaning technology, which is applied in chemical instruments and methods, lamination devices, hydraulically coagulable material layered products, etc., can solve the problems of complex preparation process and flammability of the thermal insulation layer, and achieve beautiful and durable decorative effect, Save the construction period and ensure the effect of construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0071] This embodiment provides a method for preparing a decorative insulation board, and the preparation method specifically includes the following steps:

[0072] (1) Spray a layer of vitrified microbeads in the mold to form a self-cleaning layer 1, and the surface of the vitrified microbeads is coated with TiO 2 Nano self-cleaning coating, TiO 2 The thickness of the nano self-cleaning coating is 1 μm;

[0073] (2) pour 10mm thick concrete slurry on the self-cleaning layer 1;

[0074] (3) Lay one deck metal mesh 3 and 1cm thick vitrified beads on the slurry surface successively, and vibrate the mold so that the metal mesh is embedded in the slurry;

[0075] (4) After the vibration is completed, the concrete slurry is cured at 5°C and the relative humidity is 50% under the curing conditions until it is solidified and formed, and the decorative surface layer 2 formed by the concrete slurry and the thermal insulation layer formed by the vitrified microspheres are obtained. 4...

Embodiment 2

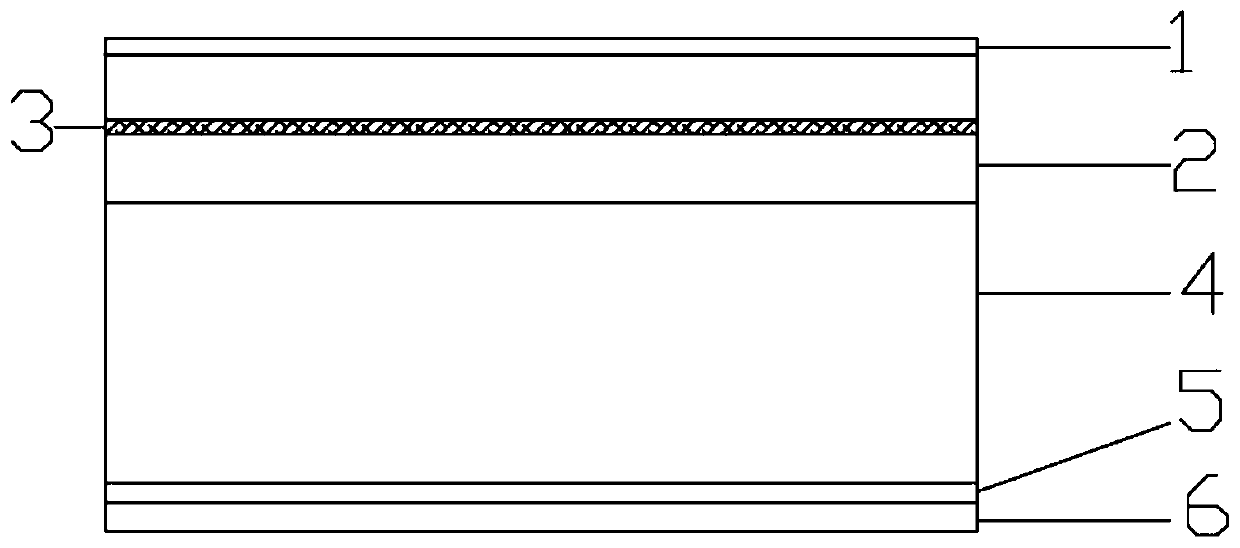

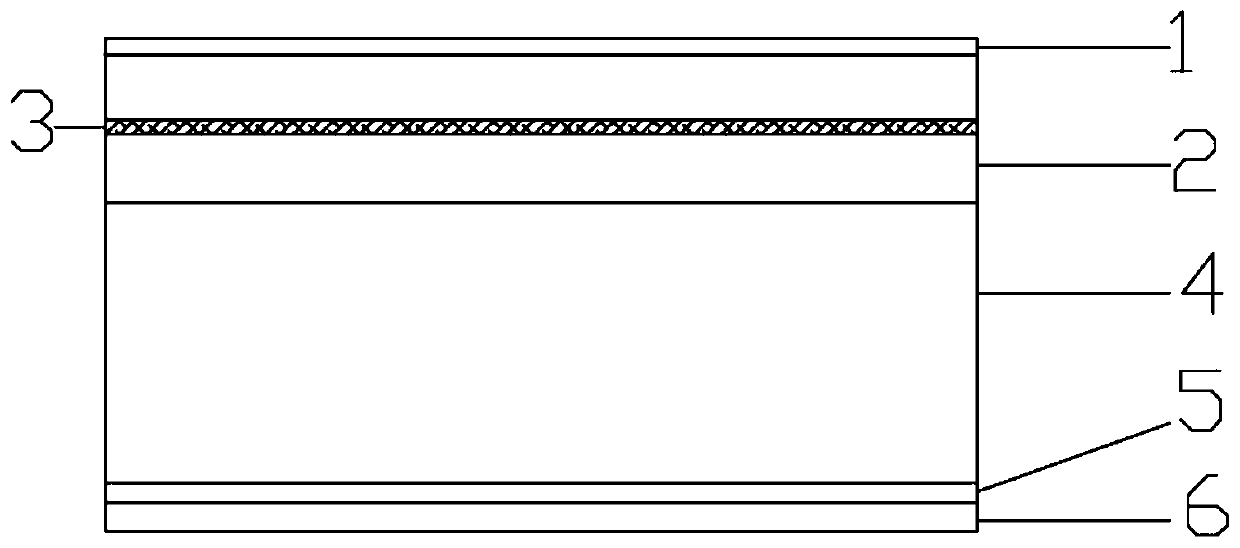

[0079] The layered structure of the decorative insulation board prepared by the preparation method provided in Example 1 is as follows: figure 1As shown, it includes a self-cleaning layer 1 , a decorative surface layer 2 , an insulating layer 4 , an adhesive layer 5 and a base layer 6 which are stacked sequentially from top to bottom.

[0080] The self-cleaning material used in the self-cleaning layer 1 is coated with TiO 2 Nano self-cleaning coated glassy beads, TiO 2 The thickness of the nano self-cleaning coating is 1 μm.

[0081] The base material used in the decorative surface layer 2 is concrete slurry with a thickness of 10mm. A layer of metal mesh 3 is embedded in the decorative surface layer 2 .

[0082] The insulating material used in the insulating layer 4 is vitrified microbeads, and the thickness of the insulating layer 4 is 1 cm.

[0083] The adhesive material used in the adhesive layer 5 includes hard foam polyurethane, and the base layer 6 is a cement-based...

Embodiment 3

[0085] This embodiment provides a method for preparing a decorative insulation board, and the preparation method specifically includes the following steps:

[0086] (1) Spray a layer of painted pottery in the mold to form a self-cleaning layer 1, and the surface of painted pottery is coated with TiO 2 Nano self-cleaning coating, TiO 2 The thickness of the nano self-cleaning coating is 5 μm;

[0087] (2) Pour 30mm thick ordinary cement mortar on the self-cleaning layer 1;

[0088] (3) Lay one deck of non-metallic mesh cloth and 5cm thick ceramsite on the surface of the slurry successively, and vibrate the mold so that the non-metallic mesh cloth is embedded in the slurry;

[0089] (4) After the vibration is completed, the ordinary cement mortar is maintained at 20° C. and the relative humidity is 60% under the curing conditions until it is solidified and formed, and the decorative surface layer 2 formed by the ordinary cement mortar and the insulation layer 4 formed by cerams...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com