Non-contact molten pool temperature measuring system and method for powder laying type laser additive manufacturing

A temperature measurement and laser additive technology, which is applied in optical radiation measurement, radiation pyrometry, measuring devices, etc., can solve the problem of high difficulty in follow-up measurement of molten pool temperature, and achieve follow-up temperature test with fast measurement response speed , The effect of high temperature measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

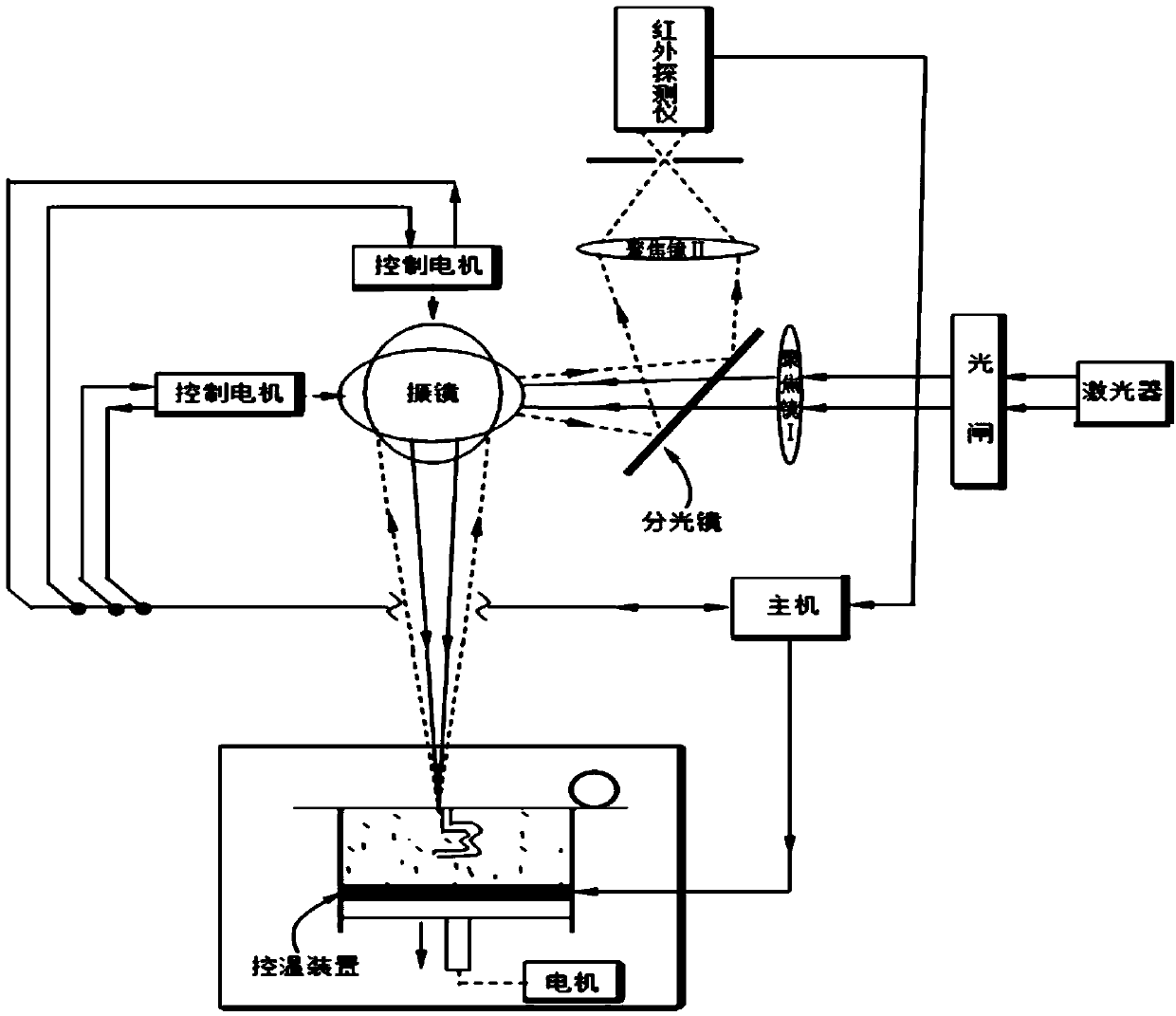

Method used

Image

Examples

Embodiment 1

[0029] The infrared thermometer used in this embodiment is a Rayteck infrared two-color thermometer, and the test process uses a single-color mode to work. The emissivity calibration of infrared temperature measurement during the test is: 0.9.

[0030] The infrared thermometer is connected through the R485 communication module, and then connected to the host computer to collect test data. The specific implementation process does not add a small hole at the front end of the infrared thermometer.

[0031] The temperature information of the molten pool in the process of powder-spraying additive manufacturing process was measured for the powder-spreading forming 316L stainless steel material with a particle size of <325 μm spherical powder. Melt pool temperature measurements were carried out under the following process parameter conditions. Additive process parameters: laser power (170 / 180 / 190 / 200W), scanning speed (200, 300, 400mm / s).

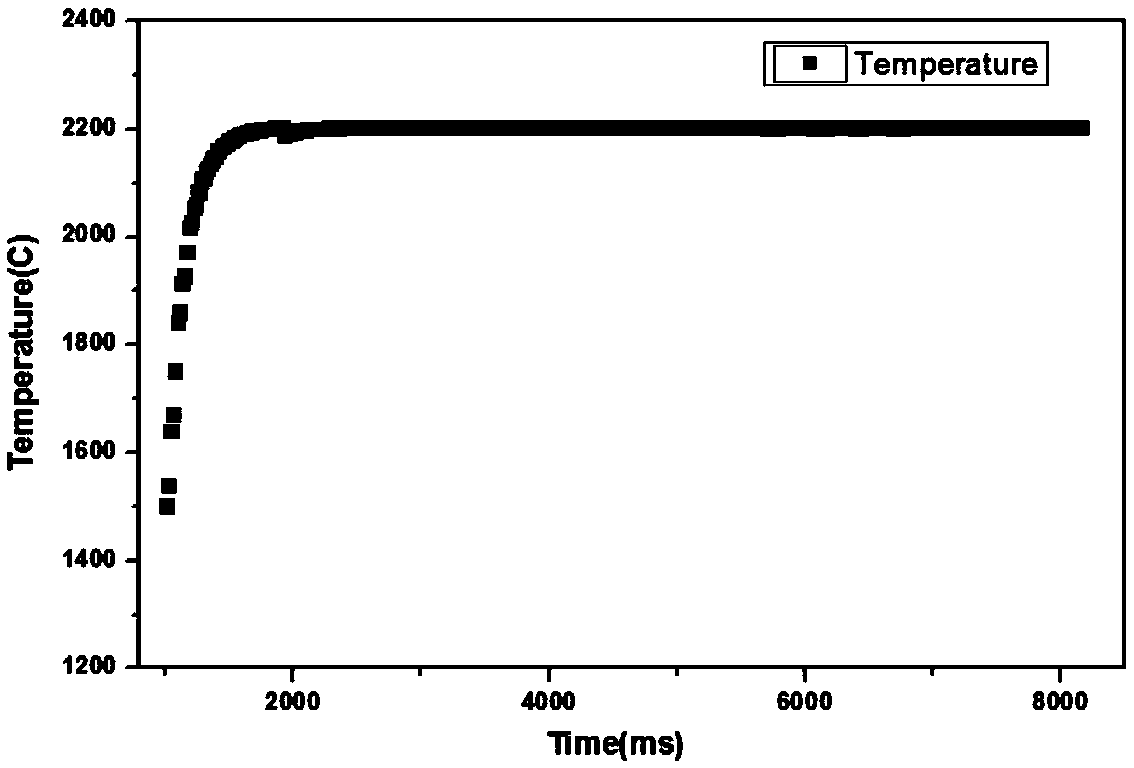

[0032] The measurement of the temperatur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com