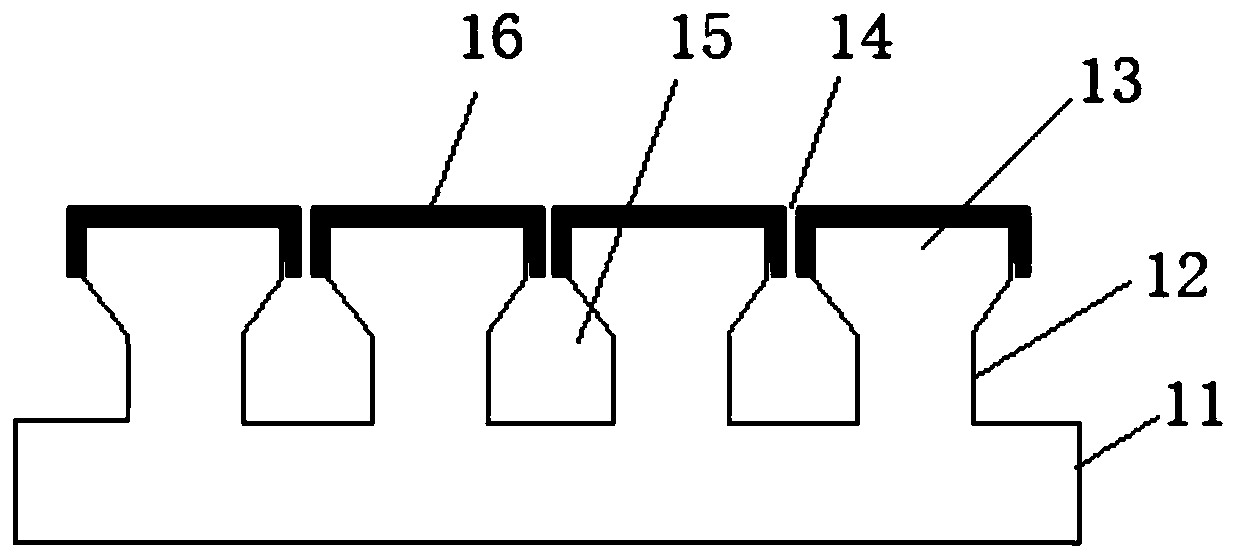

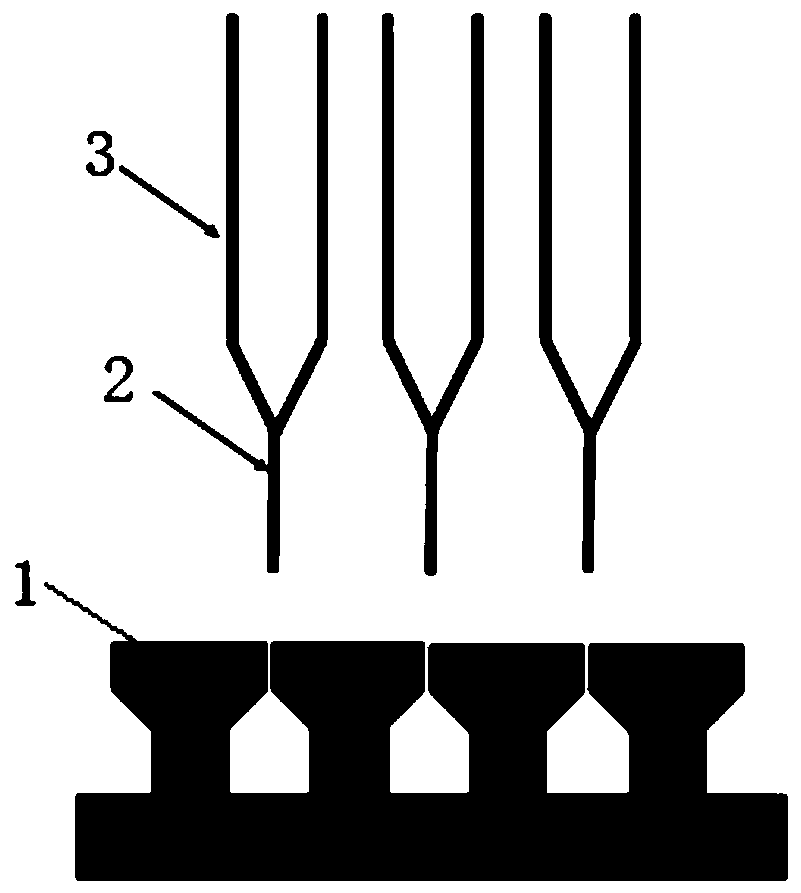

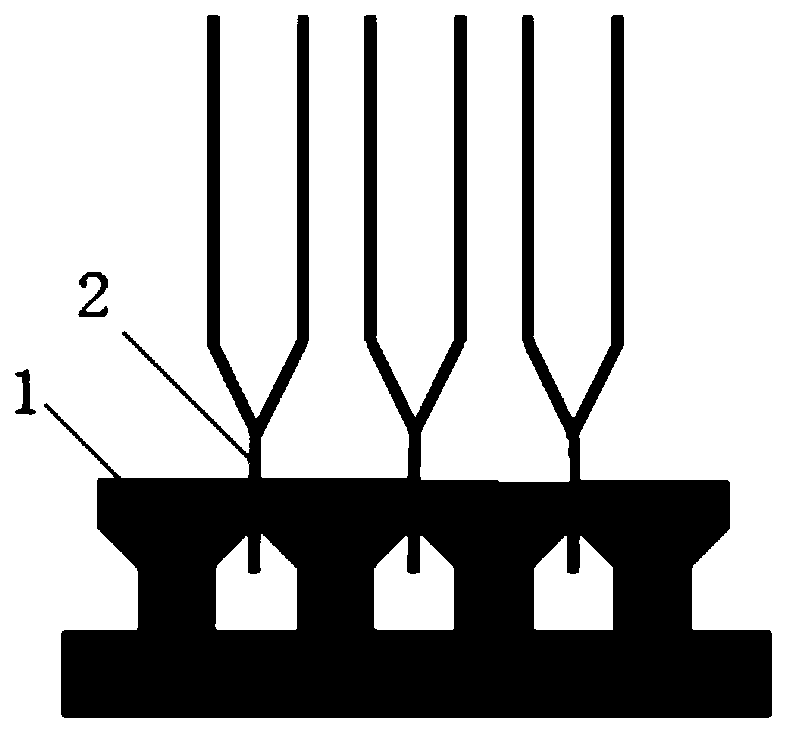

Integrated high-temperature decomposition connector and lithium ion battery comprising same

A high-temperature decomposition and connector technology, which is applied to battery pack components, circuits, electrical components, etc., can solve the problems of square battery explosion-proof valve conducting heat away, cell thermal runaway, etc., to avoid heat accumulation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] 85% polyethylene carbonate, 10% potassium hydroxide and 5% acetylene black (30nm) were used to make a cube sample with a size of 30mm.

Embodiment 2

[0049] Using 85% polypropylene carbonate, 10% potassium hydroxide and 5% carbon fiber (diameter 250nm, length 2um) to make a cube sample with a size of 30mm.

Embodiment 3

[0051] Adopt 80% polypropylene carbonate (25511-85-7, Sigma-Aldrich) and 15% sodium sulfate (Sigma-Aldrich) and 5% graphene and carbon nanotube (the size of graphene is 2um, average About 8 layers, carbon nanotubes are multi-walled, with a diameter of 20nm and a length of 400nm) made into a cubic sample with a size of 30mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com