A kind of lithium battery flexible negative electrode material and preparation method for wearable electronic equipment

A technology for negative electrode materials and electronic equipment, applied in the field of flexible negative electrode materials and preparations for lithium batteries for wearable electronic devices, can solve the problems of metal current collector fracture, low battery energy density, and complex processing technology, and achieve small diffusion distance and prevent Capacitance attenuation and good electrical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

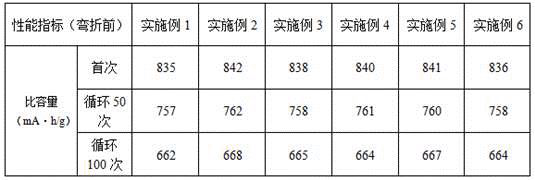

Examples

Embodiment 1

[0030] (1) Put 95 parts by weight of hydrogen peroxide solution with a mass concentration of 20% in an ice bath, add 5 parts by weight of metal molybdenum powder under stirring, place it at room temperature after the reaction is completed, and continue stirring for 4 hours to remove the remaining hydrogen peroxide. get MoO 3 ·H 2 O and MoO 3 2H 2 The sol of O is then transferred to an autoclave and heated for hydrothermal reaction, then naturally cooled to room temperature, suction filtered, washed, and vacuum-dried to obtain molybdenum trioxide nanowires; wherein: the temperature of the hydrothermal reaction is 180 ° C, the pressure The temperature is 2MPa, and the time is 4h; the temperature of vacuum drying is 80°C, and the time is 8h;

[0031] (2) Add 18 parts by weight of manganese sulfate and 10 parts by weight of molybdenum trioxide nanowires into 71.5 parts by weight of deionized water, then add 0.5 parts by weight of potassium permanganate as an oxidant, transfer t...

Embodiment 2

[0035] (1) Put 90 parts by weight of hydrogen peroxide solution with a mass concentration of 20% in an ice bath, add 10 parts by weight of metal molybdenum powder under stirring, place it at room temperature after the reaction is completed, and continue stirring for 4 hours to remove the remaining hydrogen peroxide. get MoO 3 ·H 2 O and MoO 3 2H 2The sol of O is then transferred to an autoclave and heated for hydrothermal reaction, then naturally cooled to room temperature, suction filtered, washed, and vacuum-dried to obtain molybdenum trioxide nanowires; wherein: the temperature of the hydrothermal reaction is 200 ° C, the pressure The temperature is 3MPa, and the time is 3h; the temperature of vacuum drying is 90°C, and the time is 4h;

[0036] (2) Add 17 parts by weight of manganese sulfate and 18 parts by weight of molybdenum trioxide nanowires into 64.8 parts by weight of deionized water, then add 0.2 parts by weight of potassium permanganate as an oxidant, transfer t...

Embodiment 3

[0040] (1) Put 92 parts by weight of hydrogen peroxide solution with a mass concentration of 20% in an ice bath, add 8 parts by weight of metal molybdenum powder under stirring, place it at room temperature after the reaction is completed, and continue stirring for 5 hours to remove the remaining hydrogen peroxide. get MoO 3 ·H 2 O and MoO 3 2H 2 The sol of O is then transferred to an autoclave and heated for hydrothermal reaction, then naturally cooled to room temperature, suction filtered, washed, and vacuum-dried to obtain molybdenum trioxide nanowires; wherein: the temperature of the hydrothermal reaction is 190 ° C, the pressure The temperature is 2.2MPa, and the time is 3.5h; the temperature of vacuum drying is 85°C, and the time is 6h;

[0041] (2) Add 16 parts by weight of manganese sulfate and 15 parts by weight of molybdenum trioxide nanowires into 68.5 parts by weight of deionized water, then add 0.5 parts by weight of potassium permanganate as an oxidant, transf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com