Polyvinyl alcohol-based aroma sustained-release material, composite sheet and preparation thereof, and application of polyvinyl alcohol-based aroma sustained-release material and composite sheet in heat-not-burn tobacco products

A polyvinyl alcohol-based, heat-not-burn technology, applied in the preparation of tobacco, tobacco, application, etc., can solve the problems of difficulty in imparting product quality style characteristics, uneven fragrance release, etc., to achieve style characteristics, convenient storage and transportation, The effect of increasing aroma richness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

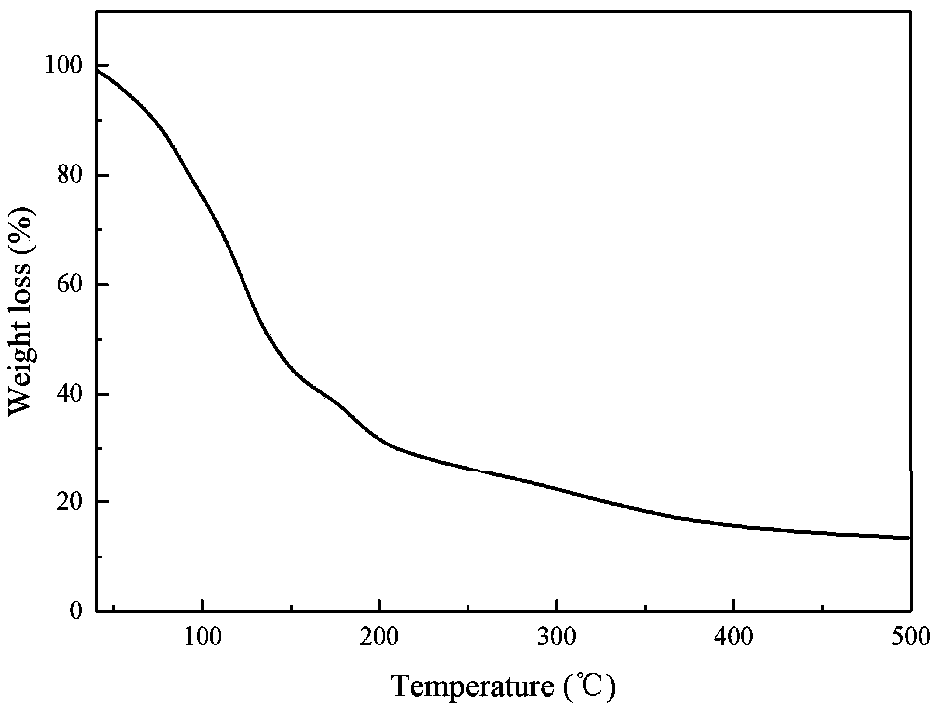

[0068] Flavor A is a commonly used conventional cigarette flavor, which is applied to heat-not-burn tobacco products in the present invention, and the flavor components contained therein mainly include: ethyl acetate, ethyl butyrate, ethyl 2-methylbutyrate, isovaleric acid Ethyl esters, furfural, hexyl caproate, 3-methyl-pyrazine, 2-ethyl-3-methylpyrazine, benzaldehyde, acetophenone, macrostigmatrienone, geranylacetone, beta- Damascenone, dihydrodamascenone, menthol, methyl phenylacetate, tobacco extract, fig extract, apple extract, date tincture, vanilla bean tincture, benzoin balm, licorice liquid extract, etc. For the thermogravimetric curve of essence A, see figure 1 , the analysis shows that when the temperature reaches 150°C, more than 60% of the essence A has been lost due to rapid volatilization. The essence is directly injected into the heating end of the heat-not-burn tobacco product with a flavoring injection device. The evaluation results show that there is a stro...

Embodiment 2

[0074] Another optimized implementation is to use an adsorbent to absorb flavors and fragrances, and then add polyvinyl alcohol solution to make flavor slow-release sheets, and apply them to the heating end of heat-not-burn tobacco products. The specific steps are as follows: take activated diatoms Pass the soil through a 40-mesh sieve, dry it in an oven at 500°C for 12 hours, and cool it at room temperature for later use; mix the essence A with 40-mesh diatomaceous earth in a ratio of 1:1, stir evenly, and place it in a room temperature environment for 0.5 hours; After dissolving polyvinyl alcohol (pharmaceutical grade, type 1788) with 10 times the volume of water, add it to the above system and stir well until the absorbing material and flavor and fragrance are evenly dispersed in the polyvinyl alcohol liquid; spread the above liquid evenly On a flat plate, the solvent is removed by hot air drying at 30°C to obtain a sustained-release sheet; it is cut into filaments with a le...

Embodiment 3

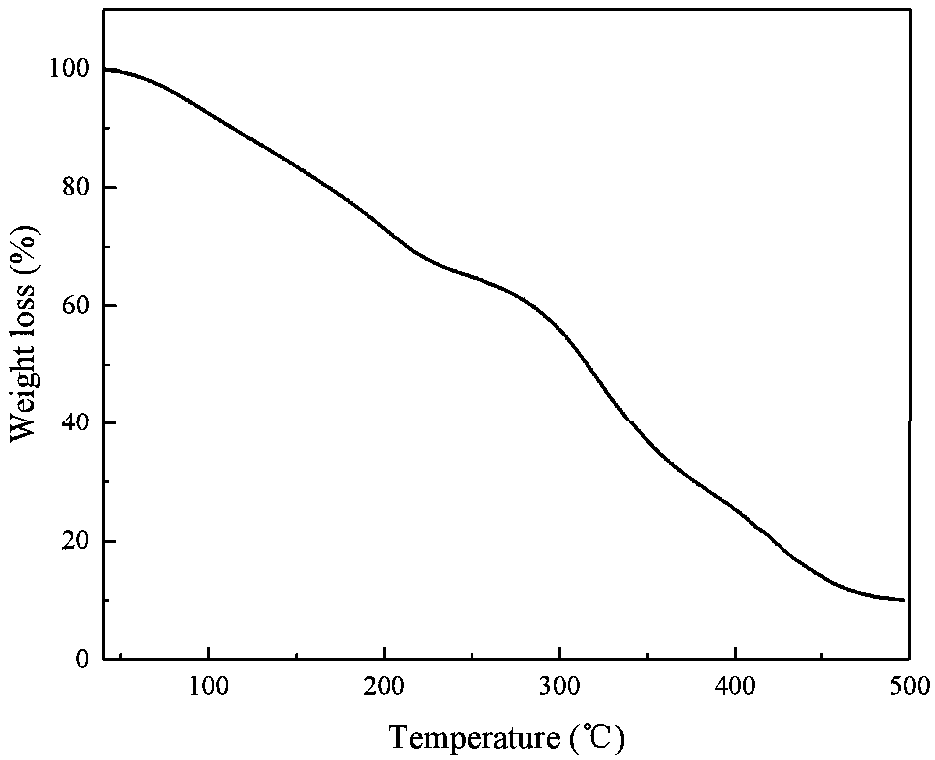

[0077] According to the method of Example 2, the adsorbent is replaced by Hβ-molecular sieve, and the essence B is used as the slow-release essence. The aroma components contained in the essence B mainly include: ethyl acetate, ethyl propionate, ethyl butyrate, isovaleric acid Ethyl esters, ethyl caproate, furfural, 3-methylpyrazine, amyl valerate, benzyl alcohol, ethyl caprylate, benzyl acetate, ethyl caprate, macrostigmazonone, beta-damascenone, Damascone, Geranylacetone, Sclare Oil, Lemon Oil, Tobacco Extract, Cocoa Extract, Vanilla Bean Tincture, Iris Extract, Licorice Fluid Extract, etc. The prepared flavor sustained-release thin slices are cut into shreds and blended into the tobacco material of heat-not-burn tobacco products. It also has a good sustained-release effect, which can make the flavors and fragrances release slowly and uniformly between 100-250°C, and release continuously The time is more than 25 minutes, and the weight loss rate is 13% within 15 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| alcoholysis degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com