Solid-phase preparation method and application of chromium-based carbon nitride catalyst

A technology for chromium-based carbon nitride and carbon-based nitride, which is applied in the field of solid-phase preparation of chromium-based carbon nitride catalysts, can solve problems such as limitation and unfavorable gas adsorption, and achieve the effects of simple operation and easy availability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

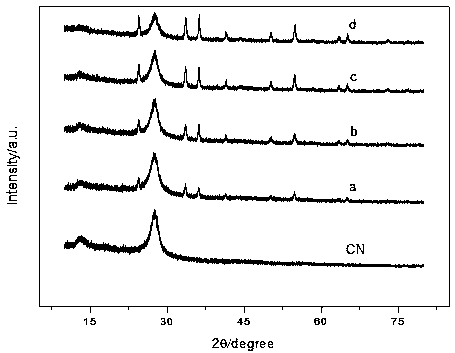

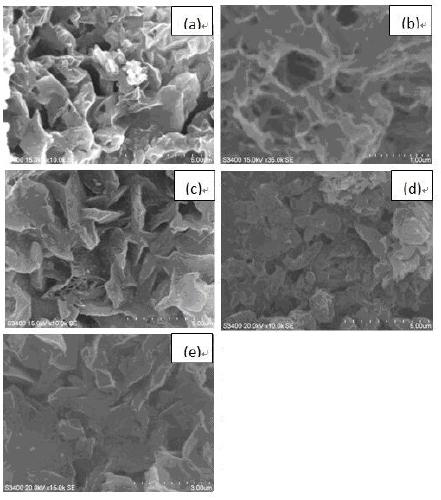

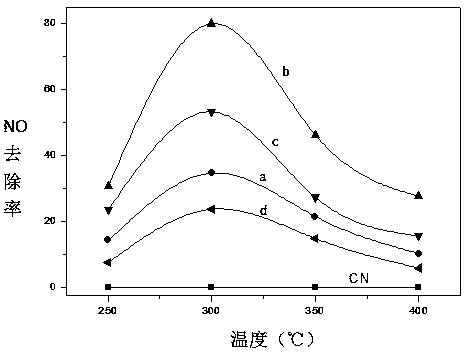

[0020] Embodiment 1, the preparation of chromium-based carbon nitride catalyst a

[0021] Step 1: Add 3.3062 g of melamine, 0.0203 g of chromium trioxide and 5.0654 g of ammonium chloride into 5 mL of ethanol solution, and grind;

[0022] Step 2: Take out the sample that has been ground in step 1, place it in a muffle furnace for calcination (calcination conditions: heat up to 520°C at a rate of 2.4°C / min, and keep it warm for 4 h), take out the sample obtained by calcination to obtain the final The product chromium-based catalyst is denoted as catalyst a.

Embodiment 2

[0023] Embodiment 2, the preparation of chromium-based carbon nitride catalyst b

[0024] Step 1: Add 3.3163 g of melamine, 0.0507 g of chromium trioxide and 5.0562 g of ammonium chloride into 5 mL of ethanol solution and grind;

[0025] Step 2: Take out the sample that has been ground in step 1, place it in a muffle furnace for calcination (calcination conditions: heat up to 520°C at a rate of 2.4°C / min, and keep it warm for 4 h), take out the sample obtained by calcination to obtain the final The product chromium-based catalyst is denoted as catalyst b.

Embodiment 3

[0026] Embodiment 3, the preparation of chromium-based carbon nitride catalyst c

[0027] Step 1: Add 3.3361 g of melamine, 0.0824 g of chromium trioxide and 5.0323 g of ammonium chloride into 5 mL of ethanol solution and grind;

[0028] Step 2: Take out the sample that has been ground in step 1, place it in a muffle furnace for calcination (calcination conditions: heat up to 520°C at a rate of 2.4°C / min, and keep it warm for 4 h), take out the sample obtained by calcination to obtain the final The product chromium-based catalyst is denoted as catalyst c.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com