Porous array electrode with two-stage structure as well as preparation method and application thereof

A porous array and porous conductive technology, applied in the field of electrolysis of water, can solve problems such as the inability to effectively increase the concentration of hydrogen-rich water and the inability to effectively generate nano-bubbles, and achieve the effects of being conducive to detachment, small bubble adhesion, and difficult to fall off.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

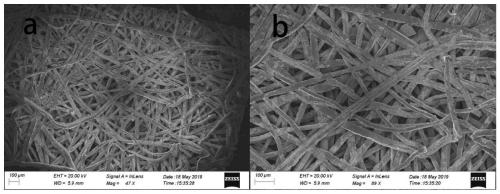

[0065] (1) Under the condition of 75° water bath, the titanium felt was etched with 10% oxalic acid solution for 1 hour. Ultrasonicate the etched titanium felt in an ultrasonic container with deionized water for 5 minutes until the surface of the etched titanium felt is cleaned.

[0066] (2) In a potassium chloride solution with a concentration of 120 mmol / L, a chloroplatinic acid solution with a concentration of 3 mmol / L is prepared and dissolved completely in ultrasound.

[0067] (3) Electrodeposition was performed using a three-electrode system in a constant temperature water bath at 25°C. Among them, the titanium felt was used as the working electrode, the platinum sheet was used as the counter electrode, and the saturated calomel electrode was used as the reference electrode. After 5 minutes of electrodeposition at a constant potential of -0.5V, it can be taken out, then rinsed with deionized water, and dried in an oven at 120°C to obtain a porous array electrode.

[00...

Embodiment 2

[0074] Referring to the method in Example 1, step (1) etched the titanium sheet with an oxalic acid solution with a mass fraction of 15% for 2 hours under the condition of a 90° water bath. In step (2), in the potassium chloride solution with a concentration of 120 mmol / L, a chloroplatinic acid solution with a concentration of 6 mmol / L is prepared and completely dissolved in ultrasound. In step (3) at -15mA / cm 2 Electrodeposition under constant current, the others are the same as in Example 1, and a porous array electrode is finally obtained.

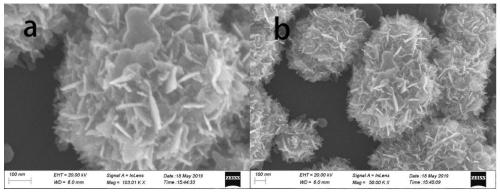

[0075] Characterize the above-mentioned titanium sheet and porous array electrode: the scanning electron microscope of the obtained titanium sheet substrate after etching can be found in the attached Figure 6 . The scanning electron microscope image of the platinum secondary array structure grown on the titanium sheet substrate can be found in Figure 7 , the overall morphology of the secondary array structure is sea urchin-like, th...

Embodiment 3

[0079] Referring to the method in Example 1, in step (3), the electrodeposition is performed using a three-electrode system under a constant temperature water bath at 50°C. Others are the same as in Example 1, and a porous array electrode is finally obtained.

[0080] Characterization of the above porous array electrodes:

[0081] The scanning electron microscope picture of the porous array electrode that embodiment 3 obtains sees Figure 11 . Figure 11 It can be seen that the length of the flakes is 50-400 nanometers, the width is 50-400 nanometers, and the thickness of the flakes is 4-15 nanometers.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com