Preparation method of silk fibroin/gelatin fiber reinforced chitosan composite haemostatic material

A silk fibroin, fiber-reinforced technology, applied in the direction of cellulose/protein conjugated artificial filament, animal fiber, fiber processing, etc., can solve the problems of insufficient mechanical properties of hemostatic materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

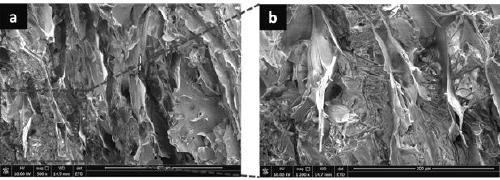

Image

Examples

preparation example Construction

[0022] The invention relates to the fields of tissue engineering and biomedical materials, and discloses a preparation method of a silk fibroin / gelatin fiber reinforced chitosan composite hemostatic material, comprising the following steps:

[0023] S1: Blend 10-20% silk fibroin aqueous solution with 4% gelatin aqueous solution, so that the mass ratio of the two is controlled at 1:1-1:4. After mixing evenly, concentrate the mixed solution to the silk fibroin mass fraction 30%~40%;

[0024] S2: Prepare the mixed solution described in S1 into a silk fibroin / gelatin composite fiber mat by electrospinning. The conditions of the electrospinning method are: the spinning voltage is 14-20 kV, and the receiving distance from the needle to the receiver is 10~15 cm, the extrusion speed of the micro syringe pump is 0.6~1.2 mL / h, the ambient temperature is 10~20 ℃, and the humidity is 40~60 RH%;

[0025] S3: Use 80 vol.% ethanol aqueous solution to post-treat the silk fibroin / gelatin comp...

Embodiment 1

[0030] Degumming silkworm cocoons with boiled sodium carbonate aqueous solution, dissolving degummed silk in lithium bromide (LiBr) aqueous solution, centrifuging, filtering, and dialysis to remove impurities and LiBr to obtain regenerated silk fibroin (RSF) aqueous solution, concentrated to RSF quality The percentage is 10% for use; gelatin (GEL) is dissolved in water to prepare a 4% GEL aqueous solution; 10% RSF aqueous solution and 4% GEL aqueous solution are blended (control GEL and RSF mass ratio is 1: 1), the mixed solution was concentrated to 30% RSF mass fraction, and the RSF / GEL composite fiber mat was obtained by electrospinning. Among them, the experimental parameters of the electrospinning method are: the relative humidity is 40±5%, the temperature is 22±5°C, the inner diameter of the needle is 0.6 mm, the voltage is 20 kV, and the receiving distance from the needle to the receiver (aluminum foil) is 10 cm , the extrusion rate of the micro-injection pump was 1.2 mL...

Embodiment 2

[0033] The difference between embodiment 2 and embodiment 1 is: embodiment 2 controls the mass ratio of GEL and RSF to be 1:4, and other operations are the same as embodiment 1, as follows:

[0034] Degumming silkworm cocoons with boiled sodium carbonate aqueous solution, dissolving degummed silk in lithium bromide (LiBr) aqueous solution, centrifuging, filtering, and dialysis to remove impurities and LiBr to obtain regenerated silk fibroin (RSF) aqueous solution, concentrated to RSF quality The percentage is 10% for use; gelatin (GEL) is dissolved in water to prepare a 4% GEL aqueous solution; 10% RSF aqueous solution is blended with 4% GEL aqueous solution (the mass ratio of GEL to RSF is 1:4 ), the mixed solution was concentrated until the mass fraction of RSF was 30%, and the RSF / GEL composite fiber mat was obtained by electrospinning. Wherein, the experimental parameters of the electrospinning method are the same as those in Example 1. The RSF / GEL composite fiber felt wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com