Radioactive microsphere and radioactive filler composition

A filling composition and radioactive technology, applied in microcapsules, tissue regeneration, drug delivery, etc., can solve the problems of tumor normal cell destruction, large radiation measurement, radiation attenuation, etc., and achieve the effect of inconvenient improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0050] The present invention also provides a method for preparing radiated microspheres, which comprises the chemical formula Ca 3 Si 2 o 7 A mixture of the indicated glass powder and yttrium oxide powder is fused to form glass; cooling the glass; grinding the glass to obtain glass powder; and flame spraying the glass powder to form radiated microspheres, wherein the sphericity of the radiated microspheres 0.71 to 1.

[0051] In a specific embodiment, the glass powder is collected in a cooling collection area after being sprayed with a flame to form radiation microspheres.

[0052] The cooling collection area can be a solid or liquid interface, the solid can be ice or dry ice, and the liquid can be a liquid (organic acid / inorganic acid) or water that can excite the components of the nuclei.

[0053] In a specific embodiment, the preparation method of the radiated microspheres further includes adding contrasting seed oxide powder into the mixture before melting the mixture. ...

Embodiment ( 1

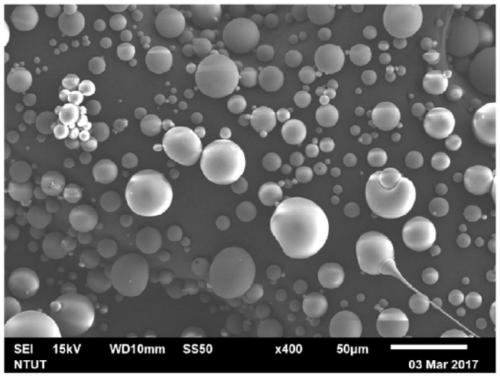

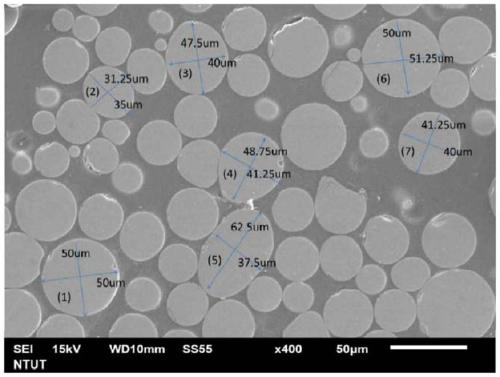

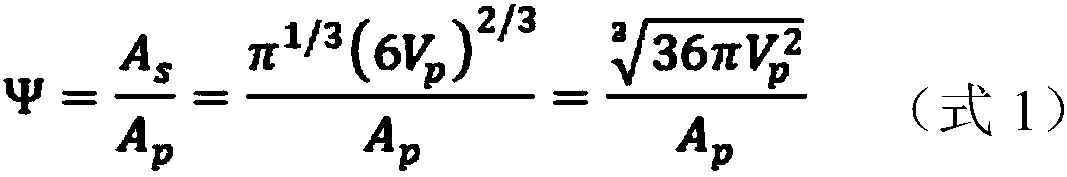

[0059] will be given by the chemical formula Ca 3 Si 2 o 7 The indicated glass powder and yttrium oxide powder are uniformly ball-milled and mixed at a molar ratio of 80:20. After being melted to form glass, the powder is ground, and then the flame is sprayed on the high-speed gas (gas) mixed with acetylene and oxygen. Ratio 1.1 to 1.2) flame heating spray, flame temperature range 1200 ℃ to 2000 ℃, spray distance 50 cm, flight time 15 seconds, form radiation microspheres, these radiation microspheres are as figure 1 shown. These radiated microspheres were sampled for Waddle sphericity analysis (e.g. figure 2 and shown in Table 1), the sphericity of the obtained radiated microspheres was between 0.7276 and 1.

[0060] A sample of 10 mg of the radioactive microspheres was subjected to neutron activation irradiation. After neutron activation elemental analysis, Ca signals were observed, as shown in Table 2.

Embodiment ( 2

[0062] will be given by the chemical formula Ca 3 Si 2 o 7 The indicated glass powder and yttrium oxide powder are uniformly ball-milled and mixed at a molar ratio of 80:20, and then 5% by weight of ReO, 5% by weight of CuO, 5% by weight of TeO and other contrasting core oxide powders are added, and melted After the glass is formed, powder grinding is carried out, and then the flame is sprayed on the high-speed gas (gas ratio 1.1 to 1.2) mixed with acetylene and oxygen, and the flame is heated and sprayed. The flame temperature range is 1200 ° C to 2000 ° C, and the spray distance is 50 cm. The flight time is 15 seconds to form radioactive microspheres. Sampling 10 mg of these radioactive microspheres with ReO, CuO, and TeO respectively, was subjected to neutron activation irradiation. After neutron activation elemental analysis, signals of Re, Cu, and Te (I-131) were observed, as shown in Table 3. Show.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com