Preparation method of low-VOC (volatile organic compound) EPDM (ethylene-propylene-diene monomer) environment-friendly flame-retardant automobile interior rubber material

A technology for automotive interiors and rubber materials, applied in the rubber field, can solve problems such as the inability to meet low VOC, and achieve the effect of ensuring odorless characteristics, good flame retardancy, and low VOC volatilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

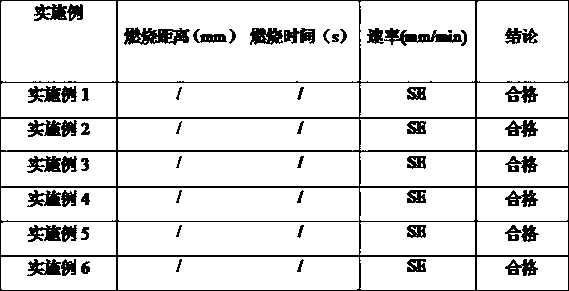

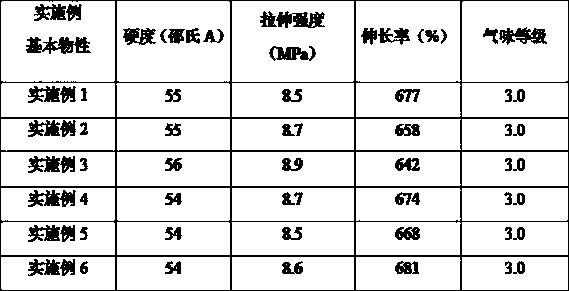

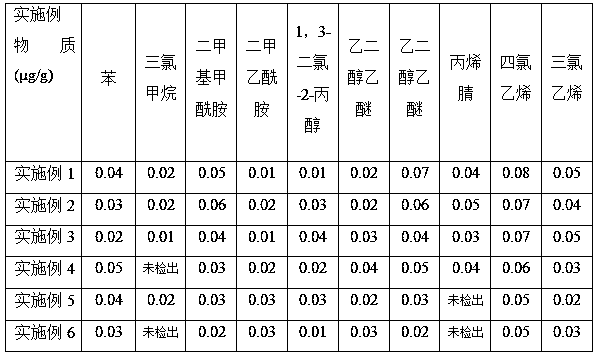

[0020] The production of low VOC EPDM environmentally friendly flame retardant automotive interior trim rubber is carried out according to the weight percentage ratio of the components in Table 1.

[0021] 1. Weighing:

[0022] Each example was weighed separately according to the following table.

[0023] Table 1 (unit: kg)

[0024]

[0025] In Table 1, the EPDM rubber is Keltan K4869C.

[0026] The high-purity carbon black is SP5000 of CABOT Company, with a purity of 99.8%.

[0027] The reinforcing filler is silica from ZEOSIL.

[0028] The flame retardant is Longsafe-201 sold by Shanghai Maotong Industrial Co., Ltd.

[0029] The softening plasticizer is high purity technical grade white oil.

[0030] The deodorant is MP60 produced by PQ Group.

[0031] The active agents are high-purity zinc oxide and stearic acid.

[0032] The accelerator is TBzTD produced by Weilin Chemical.

[0033] 2. Production steps:

[0034] 1. Ingredients:

[0035] According to the propor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com