Recombinant corynebacterium glutamicum and application thereof in producing L-glutamic acid

A technology of Corynebacterium glutamicum and glutamic acid, applied in the biological field, can solve the problems of restricting the industrial production process of L-glutamic acid and low yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

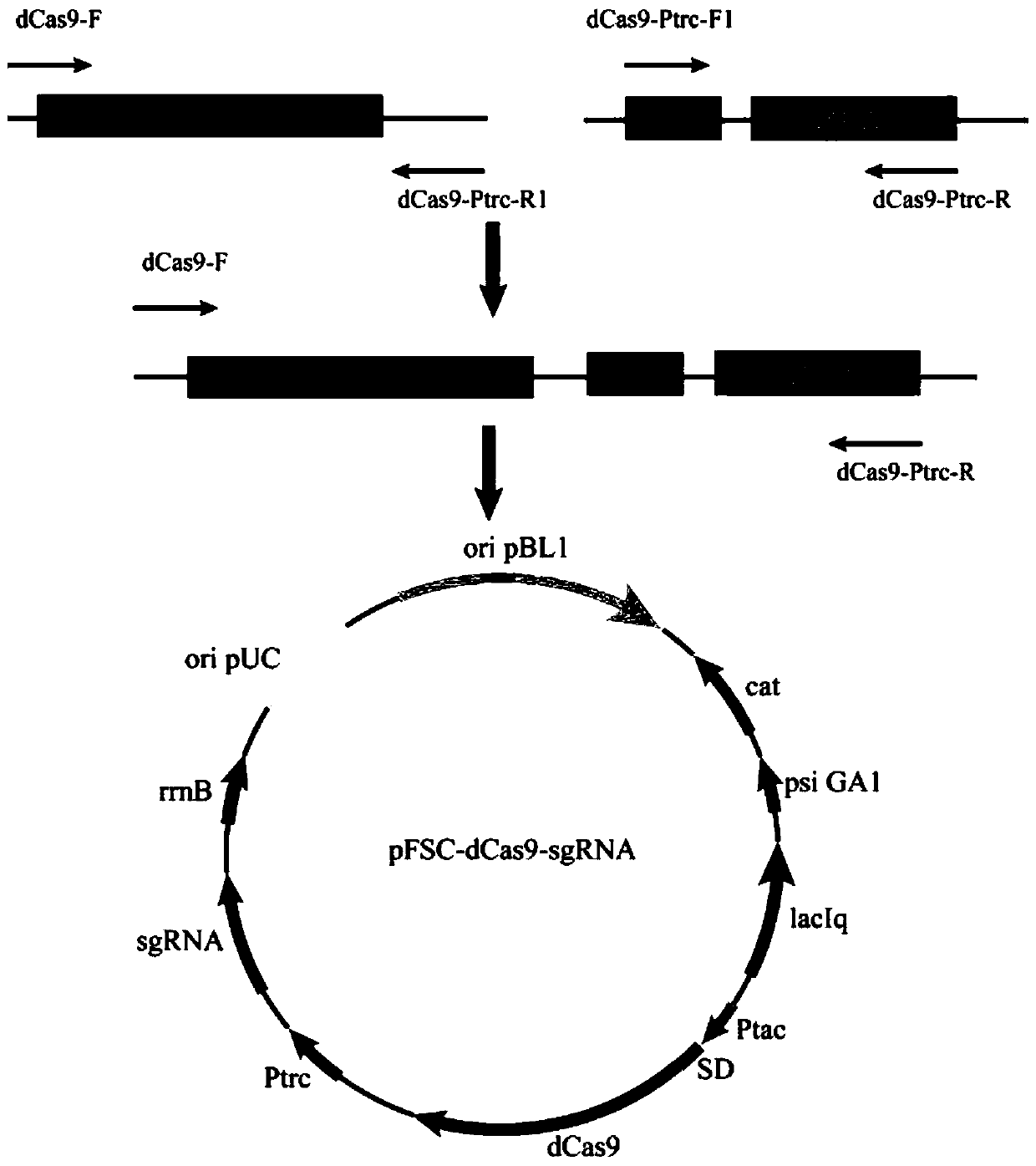

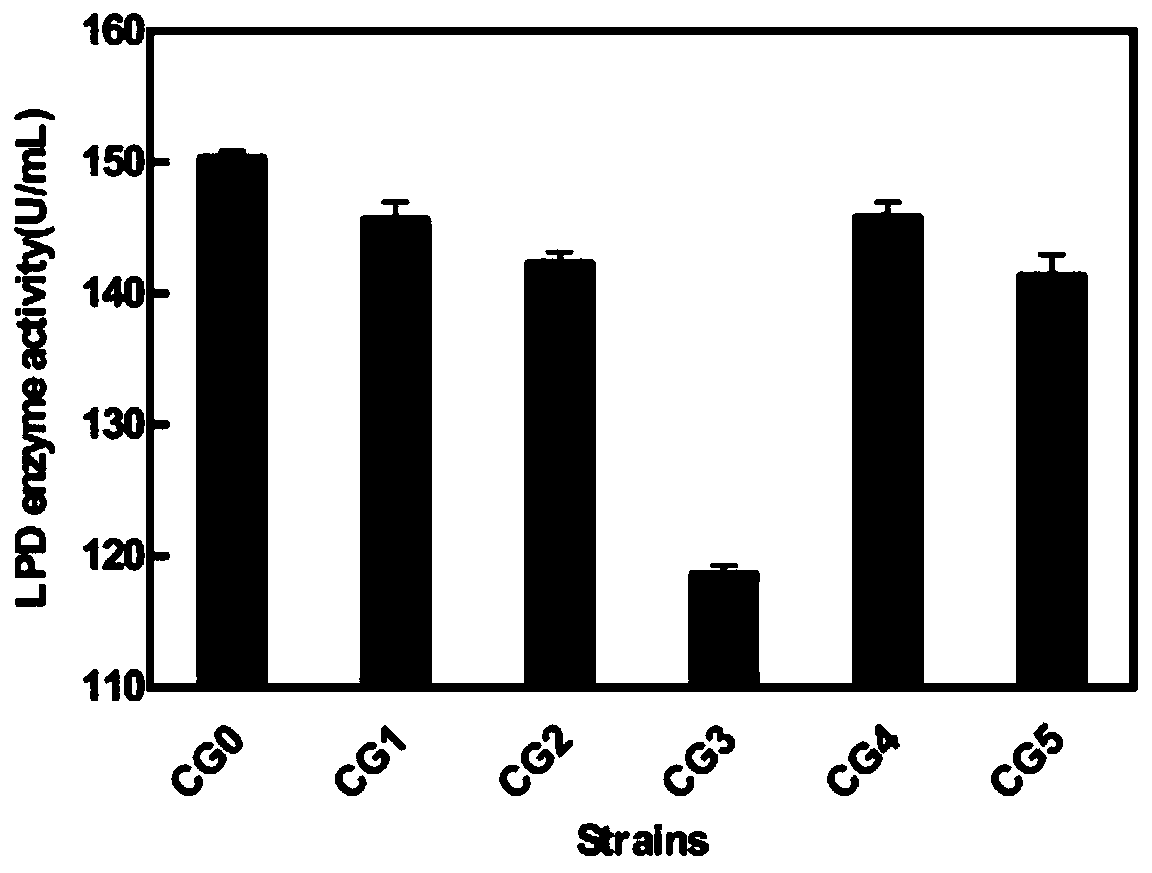

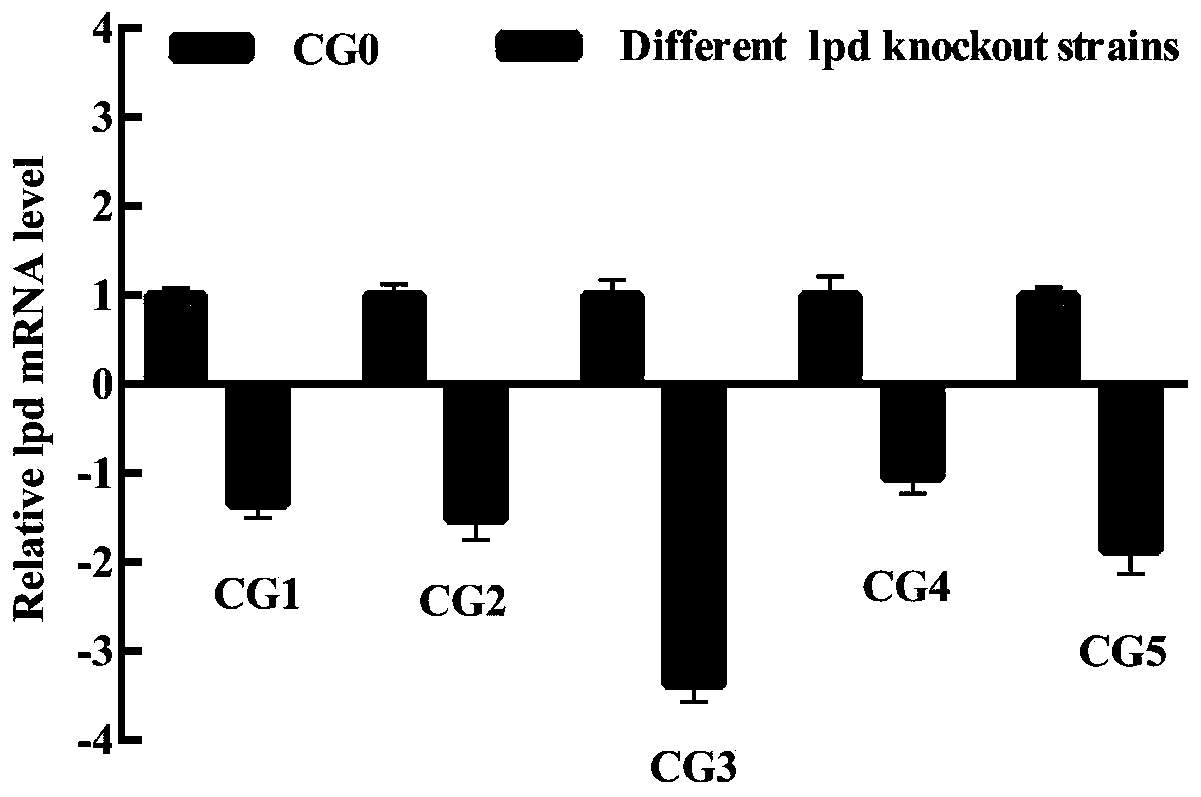

[0056] Example 1: Construction and selection of knockout plasmids

[0057] See the build process figure 1 ,Specific steps are as follows:

[0058] (1) Dip the bacteria solution of Corynebacterium glutamicum (Corynebacterium glutamicum) E01 and Corynebacterium glutamicum (Corynebacterium glutamicum) G01 from the glycerol tube and inoculate them into the seed medium, and inoculate them under the conditions of 30°C and 180r / min Cultivate under low temperature for 18 hours to the logarithmic growth phase to obtain the culture solution; centrifuge the culture solution at -4°C and 6000r / min for 10 minutes to collect the bacteria; freeze the bacteria in liquid nitrogen for 10 minutes, store them in a -80°C refrigerator, and send them to Suzhou Jinweizhi Co., Ltd. carried out total RNA extraction, total RNA-seq and resequencing analysis; concentrated analysis of genes related to the central metabolic pathway of Corynebacterium glutamicum (Corynebacterium glutamicum) E01 and Corynebac...

Embodiment 2

[0082] Example 2: Construction and fermentation of recombinant Corynebacterium glutamicum C. glutamicum DL01

[0083] Specific steps are as follows:

[0084] The knockout plasmid pFSC-dCas9-S3 obtained in Example 1 was electroporated into Corynebacterium glutamicum G01 to obtain the transformation product; the transformation product was spread on LBG medium supplemented with chloramphenicol, and placed in a 30°C constant temperature incubator Inverted culture for 36 hours to obtain transformants; Streak the transformants on LBG medium supplemented with chloramphenicol, and culture them upside down in a constant temperature incubator at 30°C for 36 hours to obtain a single colony; use dCas9-F and sgRNA-R as primers Carry out colony PCR verification (verification results see Figure 4 ), the verification is correct to obtain recombinant Corynebacterium glutamicum C. glutamicum DL01; with Corynebacterium glutamicum (Corynebacterium glutamicum) G01 as a control, a single colony o...

Embodiment 3

[0086] Example 3: Construction and fermentation of recombinant Corynebacterium glutamicum C. glutamicum G01 / pDXW-10-ppc

[0087] Specific steps are as follows:

[0088] Using the genome of Corynebacterium glutamicum G01 as a template and using pDXW-10-ppc-F and pDXW-10-ppc-R as primers for PCR amplification, the nucleotide sequence such as SEQ ID No. The gene ppc encoding phosphoenol pyruvate carboxylase shown in 4; the gene ppc encoding phosphoenol pyruvate carboxylase and the pDXW-10 plasmid are digested with restriction enzymes EcoRI and HindIII Ligation was performed to obtain the ligation product; the ligation product was transformed into Escherichia coli (Escherichia coli) JM109 to obtain the transformation product; the transformation product was coated on LB solid medium (containing 50 μg·mL -1 Kanamycin), cultured upside down in a constant temperature incubator at 37°C for 8-12 hours to obtain transformants; pick the transformants and inoculate them into LB liquid med...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com