Trivalent chromium electroplating solution and preparation method thereof

A trivalent chromium and solution technology, applied in the field of electroplating, can solve the problems of thin coating and unstable electroplating solution, and achieve the effects of improving stability, reducing sensitivity and avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

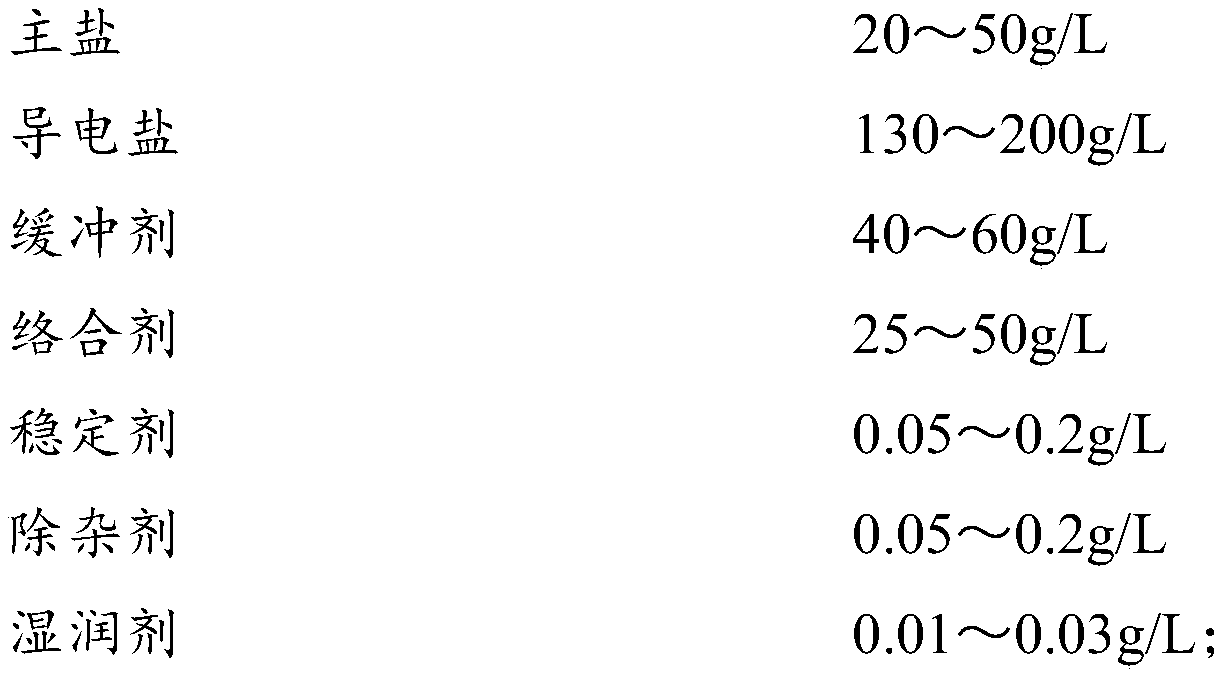

Method used

Image

Examples

Embodiment 1

[0029] The trivalent chromium electroplating solution described in this embodiment consists of: the main salt is 30g / L chromium sulfate hexahydrate, 10g / L basic chromium sulfate; the conductive salt is 120g / L sodium sulfate, 30g / L ammonium sulfate; the buffering agent is 5g / L aluminum sulfate and 45g / L boric acid; complexing agent is 30g / L formic acid, 10g / L glycolic acid; stabilizer is 0.05g / L sodium bisulfate and 0.05g / L glucosamine; impurity remover is 0.044g / L 3-amino-2-hydroxy-5-nitrobenzenesulfonic acid hydrate and 0.056g / L 3-cinnamoyl tropolone; the wetting agent is 0.02g / L sodium dodecylbenzenesulfonate.

[0030] The preparation method of trivalent chromium electroplating solution described in the present embodiment is:

[0031] S1 Soak the tank body with a sulfuric acid solution with a volume ratio of 1%, then pour water into the tank body, and heat to 60°C;

[0032] S2 Add main salt and complexing agent to the tank, stir and keep warm for 1-2 hours, then add buffer...

Embodiment 2

[0036] The trivalent chromium electroplating solution described in this embodiment consists of: the main salt is 30g / L chromium sulfate hexahydrate, 20g / L basic chromium sulfate; the conductive salt is 100g / L sodium sulfate, 50g / L ammonium sulfate, 50g / L Potassium aluminum sulfate; buffering agent is 10g / L aluminum sulfate, 50g / L boric acid; complexing agent is 25g / L formic acid, 20g / L citric acid; stabilizer is 0.03g / L sodium bisulfate and 0.03g / L glucosamine The impurity remover is 0.025g / L 3-amino-2-hydroxy-5-nitrobenzenesulfonic acid hydrate and 0.025g / L 3-cinnamoyl tropolone; the wetting agent is 0.03g / L dodecane Sodium phenyl sulfonate.

[0037] The preparation method of the trivalent chromium electroplating solution described in the present embodiment is substantially the same as in Example 1, the difference being that the pH value of the mixed solution described in S3 is 2.5.

Embodiment 3

[0039] The trivalent chromium electroplating solution described in the present embodiment consists of: the main salt is 15g / L chromium sulfate hexahydrate, 20g / L basic chromium sulfate; the conductive salt is 180g / L sodium sulfate; the buffer is 15g / L glycine, 35g / L boric acid; complexing agent is 30g / L formic acid, 20g / L citric acid; stabilizer is 0.071g / L sodium bisulfate and 0.089g / L glucosamine; impurity remover is 0.08g / L 3-amino- 2-Hydroxy-5-nitrobenzenesulfonic acid hydrate and 0.08g / L 3-cinnamoyl tropolone; the wetting agent is 0.02g / L sodium dodecylbenzenesulfonate.

[0040] The preparation method of the trivalent chromium electroplating solution described in the present embodiment is basically the same as in Example 1, the difference being that the pH value of the mixed solution described in S3 is 3.0.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com