A kind of r-t-b magnet material and its preparation method and application

A R-T-B, magnet technology, applied in the manufacturing of magnetic materials, magnetic objects, inductors/transformers/magnets, etc., can solve the problems of poor magnetic properties and small diffusion of magnet materials, achieve good coercivity and remanence, and difficulty in production Small, small effect of oxidation control requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

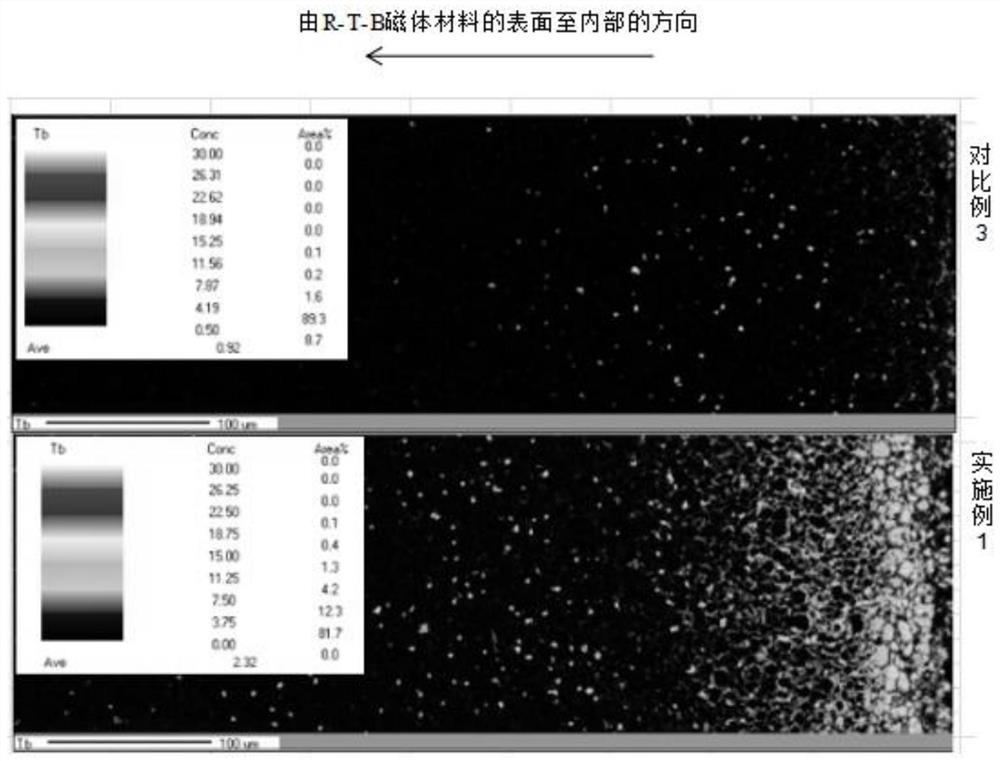

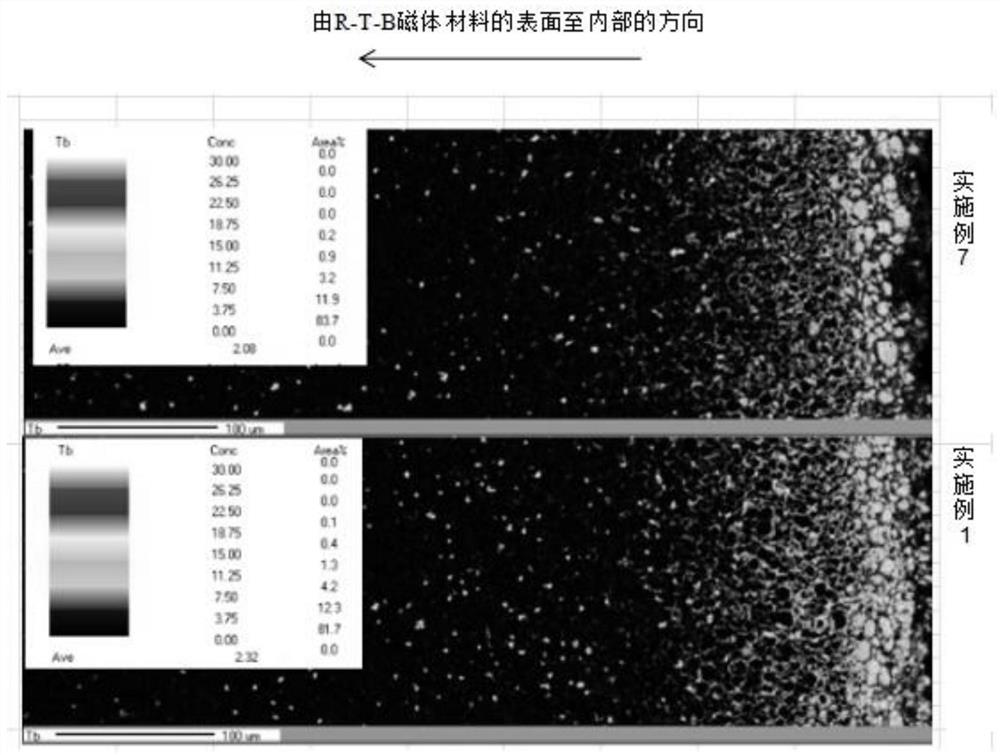

Examples

Embodiment 1

[0090] The raw material formula of R-T-B magnet material in the present embodiment is as shown in table 1 below:

[0091] Table 1

[0092]

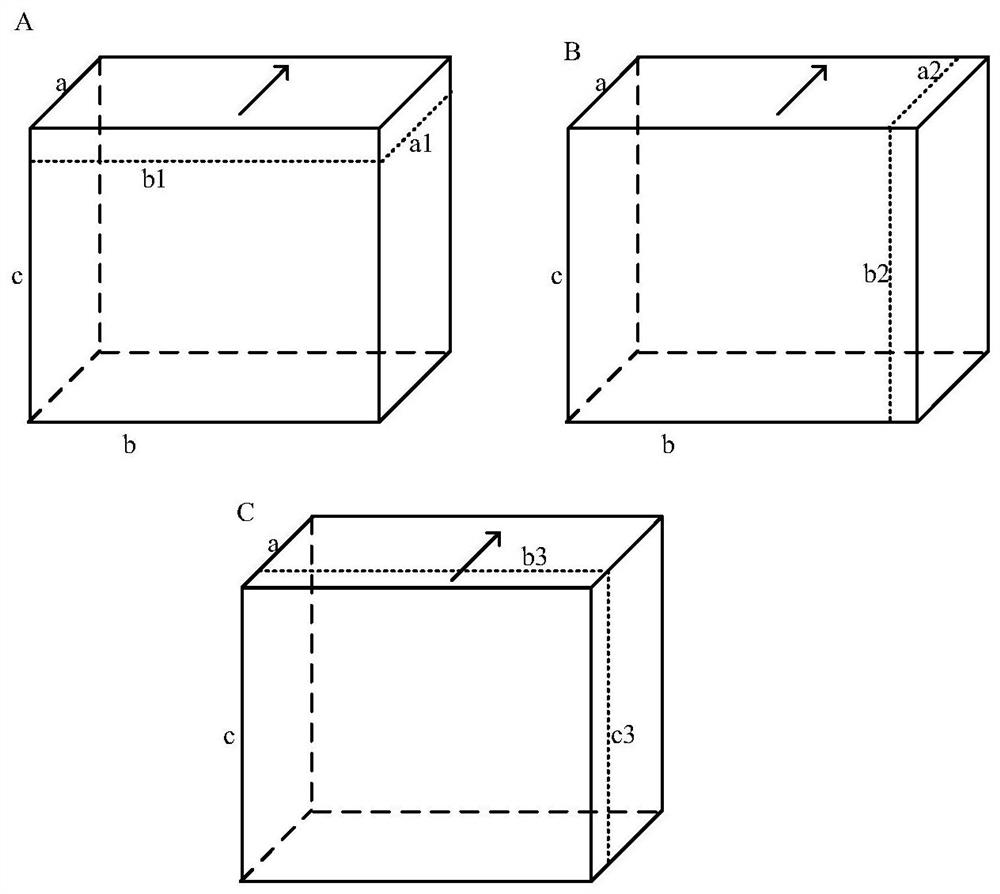

[0093] (1) According to the raw material formula in Table 1, a blank was prepared by smelting, casting, hydrogen crushing, pressing and sintering. The size of the blank was 65 (length)×50 (pressing direction)×40mm (orientation direction).

[0094] Among them, smelting and casting: the raw material formula for smelting in Table 1 is placed in an intermediate frequency vacuum induction quick-setting belt furnace for smelting and casting, and the frequency of the intermediate frequency is 1500-2500 Hz. The melting temperature is 1450-1550°C, and the casting temperature is 1350-1500°C. Alloy flakes of 0.2-0.4mm are obtained after melting and casting.

[0095] Hydrogen powder making: Introduce hydrogen gas with a purity of 99.9% into the hydrogen furnace, maintain the hydrogen pressure at 0.15Mpa, after fully absorbing hydrogen, heat up w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com