Interpenetrating network polymer type super porous aquogel, its prepn. method and application

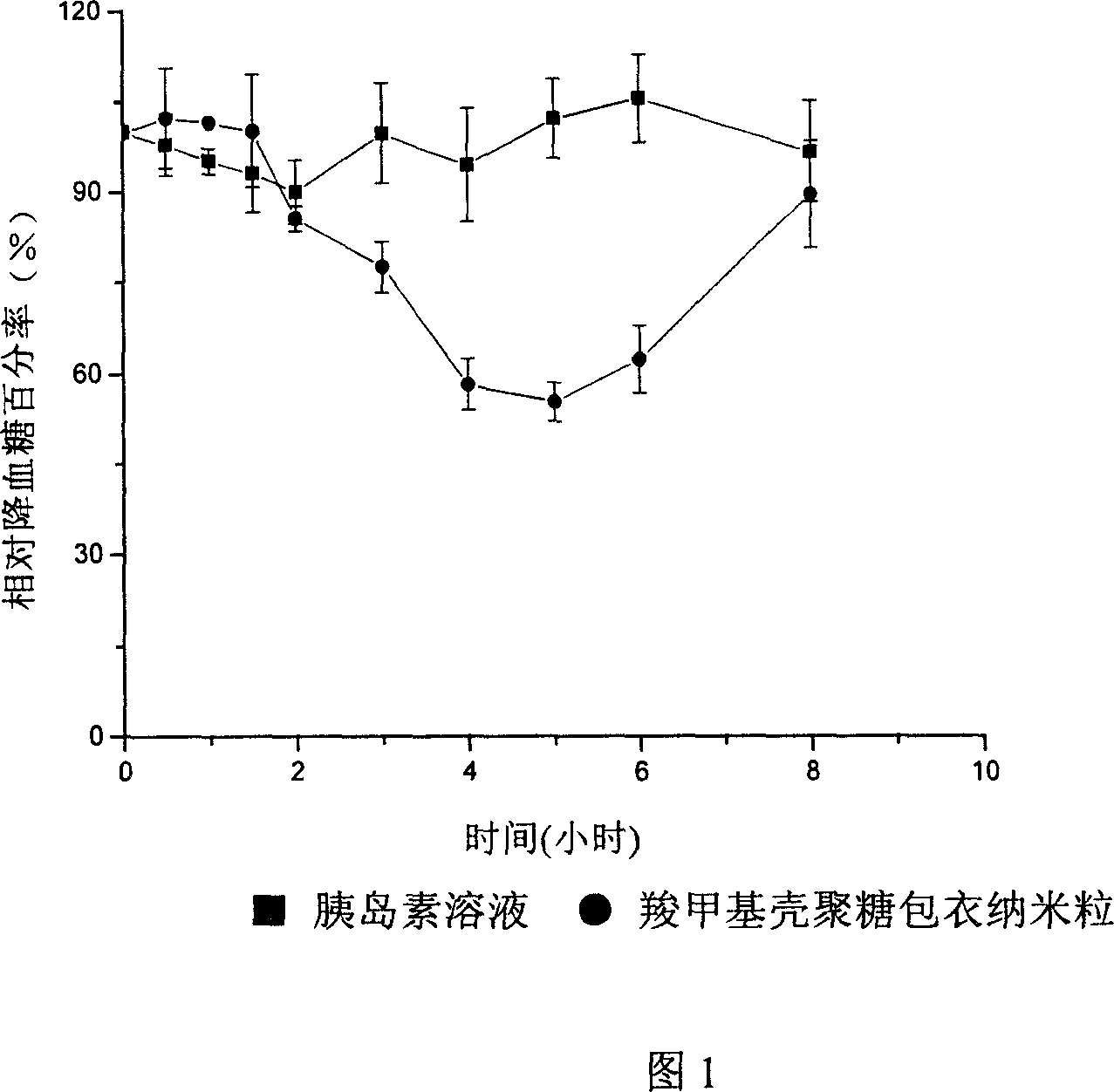

A technology of porous hydrogel and interpenetrating network is applied in the field of interpenetrating network polymer superporous hydrogel and its preparation, which can solve the problems of inflexibility, brittleness, and inappropriate oral administration of protein and polypeptide drugs, etc. Achieve the effect of increasing mechanical strength, inhibiting protease, and protecting protein and polypeptide substances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Embodiment 1 poly(acrylic acid-acrylamide) IPN-SPH containing chitosan

[0048] In a tall weighing bottle (40mm×25mm), add the following components in sequence: 300μl 50% AM (acrylamide); 200μl 50% AA (acrylic acid); 100μl 2.5% BIS (N, N'-methylene -bisacrylamide); 300 μl DDW (double distilled water); 30 μl 10% Pluronic F127 (PF127, poloxamer); 25 μl 20% APS (ammonium persulfate); 25 μl 20% TEMED (N,N,N',N'-tetramethylethylenediamine); 300 μl 4% shell Glycans (dissolved in 2% acetic acid). After each ingredient is added, the solution is vortexed to mix. Add 120 mg of sodium bicarbonate 2 minutes before gelation occurs and vortex. Place the above-mentioned ultraporous hydrogel polymer containing chitosan in HCl / absolute ethanol (3:7, v / v) containing 1% glutaraldehyde for 2h to obtain the poly( Acrylic acid-acrylamide) IPN-SPH.

Embodiment 2

[0049] Embodiment 2 contains poly(acrylic acid-acrylamide) IPN-SPH of chitosan hydrochloride

[0050] In a tall weighing bottle (40mm × 25mm), add the following ingredients in turn: 300μl 50% AM (acrylamide): 200μl 50% AA (acrylic acid); 100μl 2.5% BIS (N, N'-methylene -bisacrylamide); 300 μl DDW (double distilled water); 30 μl 10% Pluronic F127 (PF127, poloxamer); 25 μl 20% APS (ammonium persulfate); 25 μl 20% TEMED (N,N,N',N'-tetramethylethylenediamine); 300 μl 4% shell Polysaccharide hydrochloride. After adding each ingredient, the solution was vortexed to mix. Add 120 mg of sodium bicarbonate 2 minutes before gelation occurs and vortex. Place the above-mentioned ultraporous hydrogel polymer containing chitosan hydrochloride in HCl / absolute ethanol (3:7, v / v) containing 1% glutaraldehyde for 2h to obtain chitosan-containing Poly(acrylic acid-acrylamide) IPN-SPH hydrochloride.

Embodiment 3

[0051] Embodiment 3 contains the poly(acrylic acid-acrylamide) IPN-SPH of chitosan trimethyl quaternary ammonium salt (TMC)

[0052] In a tall weighing bottle (40mm×25mm), add the following components in sequence: 300μl 50% AM (acrylamide); 200μl 50% AA (acrylic acid); 100μl 2.5% BIS (N, N'-methylene -bisacrylamide); 300 μl DDW (double distilled water); 30 μl 10% Pluronic F127 (PF127, poloxamer); 25 μl 20% APS (ammonium persulfate); 25 μl 20% TEMED (N, N, N', N'-tetramethylethylenediamine); 300 μl 8% TMC . After adding each ingredient, the solution was vortexed to mix. Add 120 mg of sodium bicarbonate 2 minutes before gelation occurs and vortex. The above-mentioned superporous hydrogel polymer containing TMC is placed in HCl / dehydrated alcohol (3:7, v / v) containing 1% glutaraldehyde for 4h, and then trimethyl quaternary ammonium containing chitosan can be obtained. Poly(acrylic acid-acrylamide) IPN-SPH of salt (TMC).

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com