Nanowire-shaped spherical alumina with large aspect ratio and preparation method thereof

A spherical alumina, large aspect ratio technology, applied in alumina/aluminum hydroxide and other directions, can solve the problems of high cost of SB powder, pollution, complicated process, etc., and achieve the effect of low price, low cost and simple steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] (1) Take 66g of aluminum isopropoxide, add it into 600ml of deionized water and stir until it is completely hydrolyzed, and then evaporate the isopropanol from the solution at 95°C. Add deionized water to 600g, add 6.2g acetic acid, and stir at 95°C for 0.5h.

[0023] (2) Transfer the obtained reaction mixture into a reaction kettle, seal it, perform a hydrothermal reaction at 150° C. for 6 hours, and obtain a sol after the reaction is completed and cooled to room temperature.

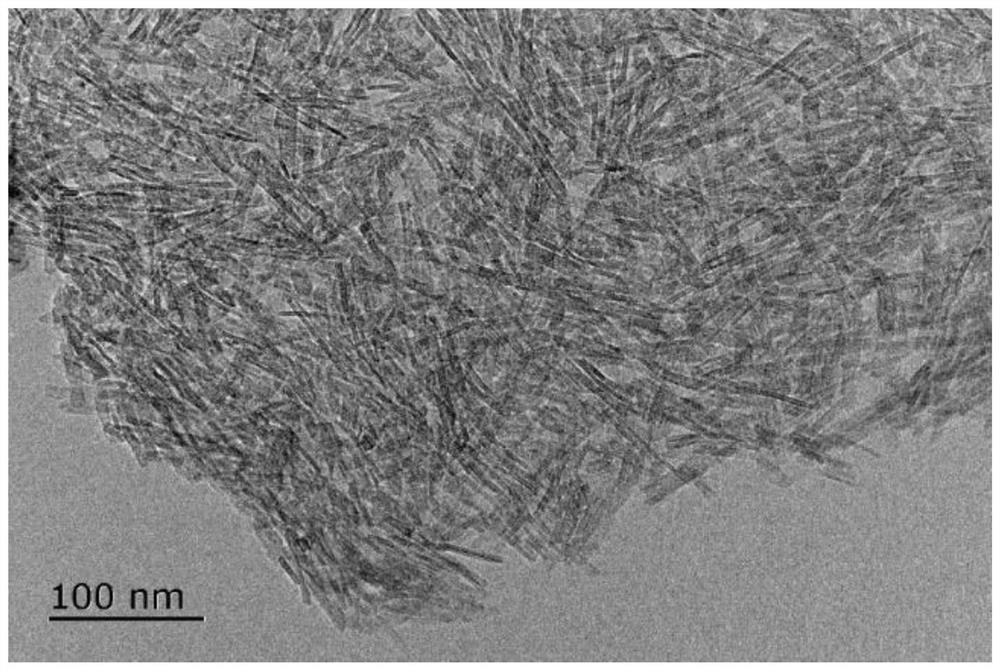

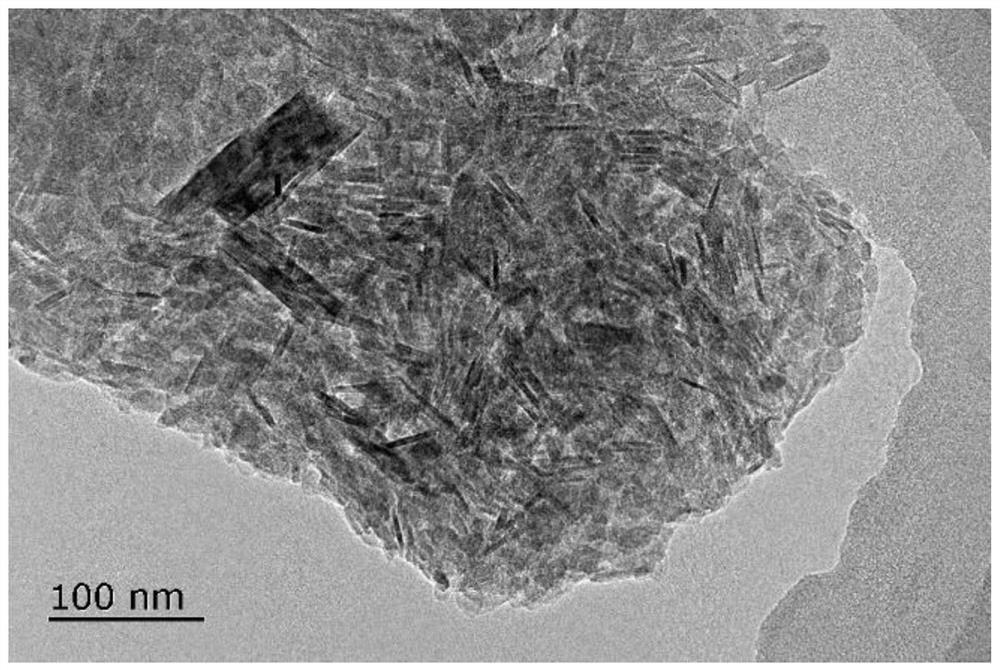

[0024] (3) Rotating the sol at 50° C. to prepare a boehmite sol with a mass fraction of 16.9% for use. The microstructure of the sol was observed by transmission electron microscopy, and the results were as follows: figure 1 shown. It can be seen that the boehmite sol has a one-dimensional nanowire microstructure with a diameter of 2-5 nm, a length of 100-2000 nm, and an aspect ratio of 20-1000.

[0025] (4) In the oleylamine column with a length of 1.5m and a diameter of 40mm, first add 8% a...

Embodiment 2

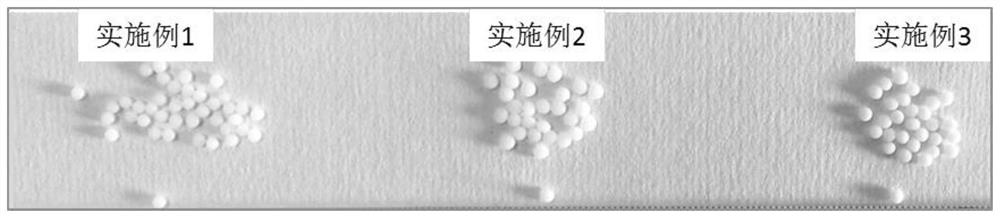

[0027] Al prepared by the method of embodiment 1 2 o 3 The difference is that the boehmite sol concentration is 25.8% in the step (3), and the diameter of the prepared bead is about 2.5mm, and the appearance is visible. image 3 ,From image 3 It can be seen from the figure that the outer surface of the pellets is smooth, spherical and uniform in particle size, and their physical properties are shown in Table 1.

Embodiment 3

[0029] Al prepared by the method of embodiment 1 2 o 3 Beads, the difference is that the boehmite sol concentration is 30.35% in the step (3), and the diameter of the made bead is about 3mm, and the outward appearance sees image 3 ,From image 3 It can be seen from the figure that the outer surface of the pellets is smooth, spherical and uniform in particle size, and their physical properties are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com