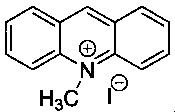

10-methyl acridine iodide and sodium citrate composite scale and corrosion inhibitor

A technology of scale and corrosion inhibitor, sodium citrate, applied in descaling and water softening, chemical instruments and methods, special treatment targets, etc. Degradability and poor scale inhibition performance, etc., to achieve the effect of good scale and corrosion inhibition comprehensive performance, broad market application prospects, and simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Corrosion inhibition performance measurement method: prepare composite scale and corrosion inhibitor solutions with concentrations as shown in Table (1) respectively with seawater. At 40°C, fix the carbon steel sheet on the plate mounter, completely immerse it in the test solution, keep the rotating speed at 75rpm for 72h, and record the weight of the test piece before and after the experiment. According to the formula: v = (w 1 -w 2 ) / (s×t) to calculate the corrosion efficiency, where w 1 and w 2 (mg) is the weight loss of the sample before and after soaking, s (cm -2 ) is the area of the steel sample, and t(h) is the soaking time; η w =(v 0 -v) / v 0 Calculate the corrosion inhibition efficiency, where v and v 0 are the corrosion rates without and with inhibitors, respectively.

Embodiment 2

[0020] Calcium carbonate scale performance test method: Calcium carbonate deposition method is used to measure the scale inhibition performance according to the national standard GB / T16632-2008. Put the compound scale and corrosion inhibitor solution prepared in Table (2) in a water bath at 70°C for 10 hours. After the solution is cooled to room temperature, filter it, and titrate the residual Ca in the filtrate with EDTA. 2+ Concentration, and make a blank sample at the same time. According to the formula η s =([Ca 2+ ] f -[Ca 2+ ] o ) / ([Ca 2+ ] i -[Ca 2+ ] o ) to calculate the scale inhibition efficiency, where [Ca 2+ ] f is the Ca in the filtrate after heating in the presence of antiscalant 2+ concentration, [Ca 2+ ] o Indicates Ca in the filtrate after heating without antiscalant 2+ concentration, [Ca 2+ ] i is the Ca in the starting solution 2+ concentration.

[0021] The corrosion and scale inhibition rates of the above two examples of scale and corrosi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com