Tail water advanced treatment device and treatment method

A sewage treatment device and advanced treatment technology, applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problem of large mud production, large floor area, and inconvenient maintenance and management And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

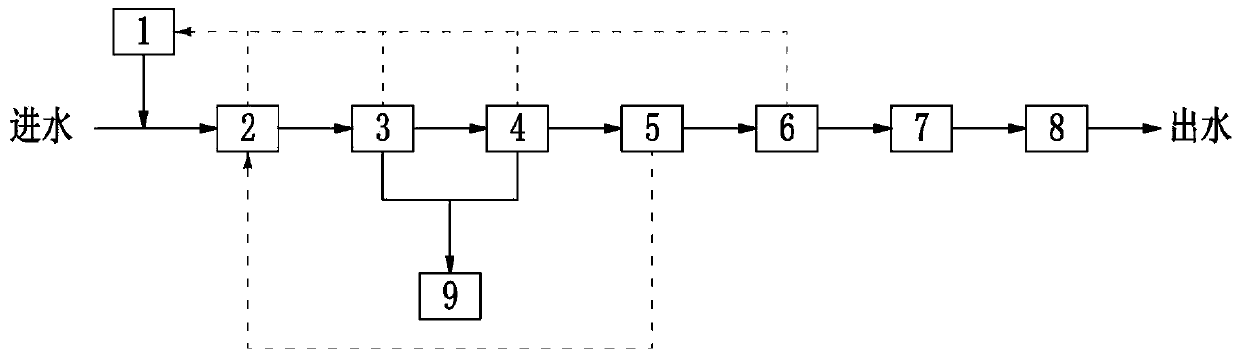

[0095] use as figure 1 The tail water advanced treatment device shown is for township sewage treatment; among them, the design flow rate is 1000m 3 / d, the average daily treated water volume is 800m 3 / d;

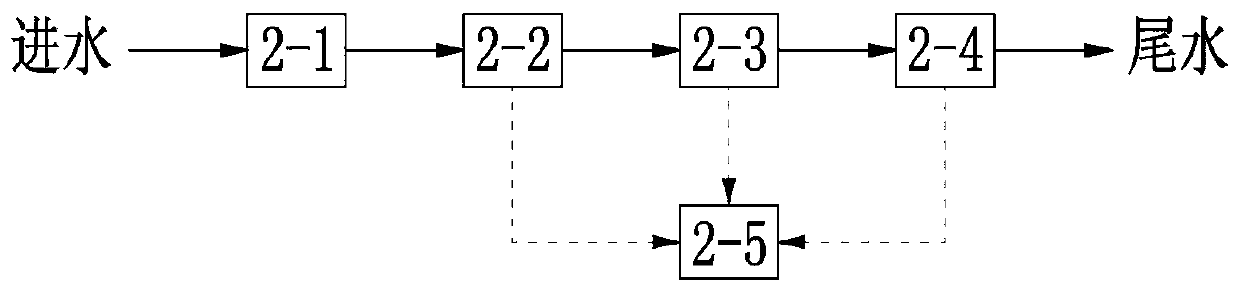

[0096] The sewage treatment device 2 is a DMBR double-membrane integrated equipment based on the MBR process, such as figure 2 As shown, it includes a grille 2-1, a denitrification adjustment tank 2-2, a biochemical reaction tank 2-3 and a filter tank 2-4 connected in sequence; the denitrification adjustment tank 2-2 is provided with a first sludge outlet , the biochemical reaction tank 2-3 is provided with a second sludge outlet, the filter tank 2-4 is provided with a third sludge outlet, the first sludge outlet, the second sludge outlet and the third sludge outlet The outlet is independently connected to the feed port of the sludge thickening tank 2-5; the sewage outlet of the sludge thickening tank 2-5 is connected to the feed port of the excess sludge liquefaction d...

Embodiment 2

[0109] use as figure 1 The tail water advanced treatment device shown is used for township sewage treatment; among them, the design flow rate is 800m 3 / d, the average daily treated water volume is 500m 3 / d;

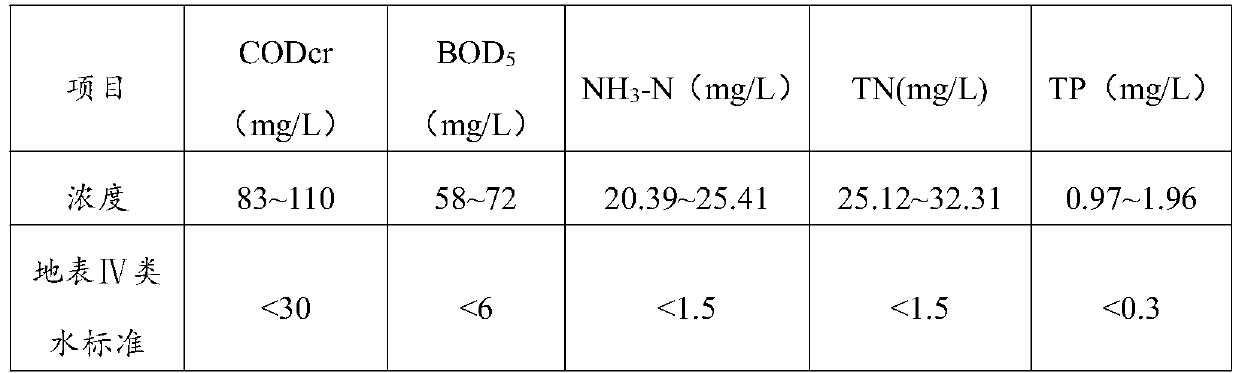

[0110] The sewage treatment device 2 is a DMBR double-membrane integrated equipment based on the MBR process, such as figure 2 shown. Due to the discharge of slaughter wastewater into the pipe network, the concentration of ammonia nitrogen and total phosphorus pollutants in the water is relatively high. figure 1 The water quality of influent water is shown in Table 3;

[0111] The water quality of table 3 embodiment 2 inlet water

[0112]

[0113] Tail water advanced treatment method is as follows:

[0114] (1) Sludge liquefaction and recovery of carbon sources: the excess sludge of the sludge concentration unit of the sewage treatment plant 2 enters the excess sludge liquefaction plant 1 for hydrolysis and acidification to obtain a hydrolyzate; the hydrolysis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com