Graphene geopolymer material as well as preparation method, application and regeneration method thereof

A geopolymer and graphene technology, applied in cement production, etc., can solve the problems of difficult sludge treatment and high treatment cost, and achieve the effects of controllable coagulation time, good toughness and reduced material waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

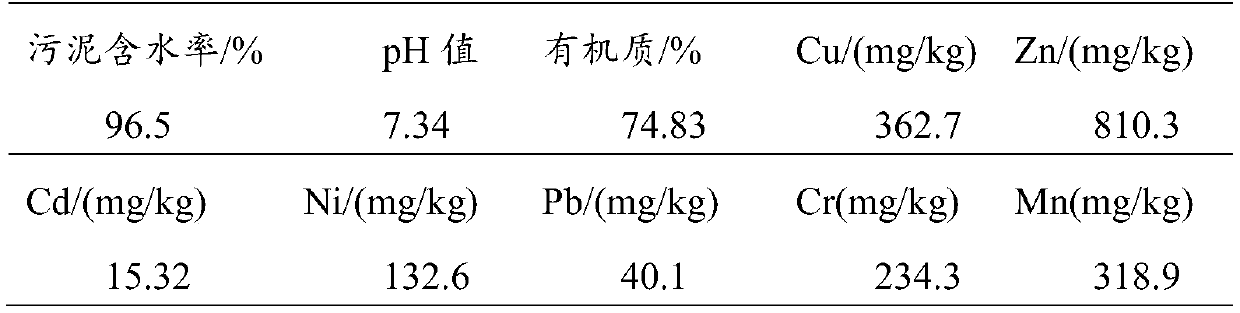

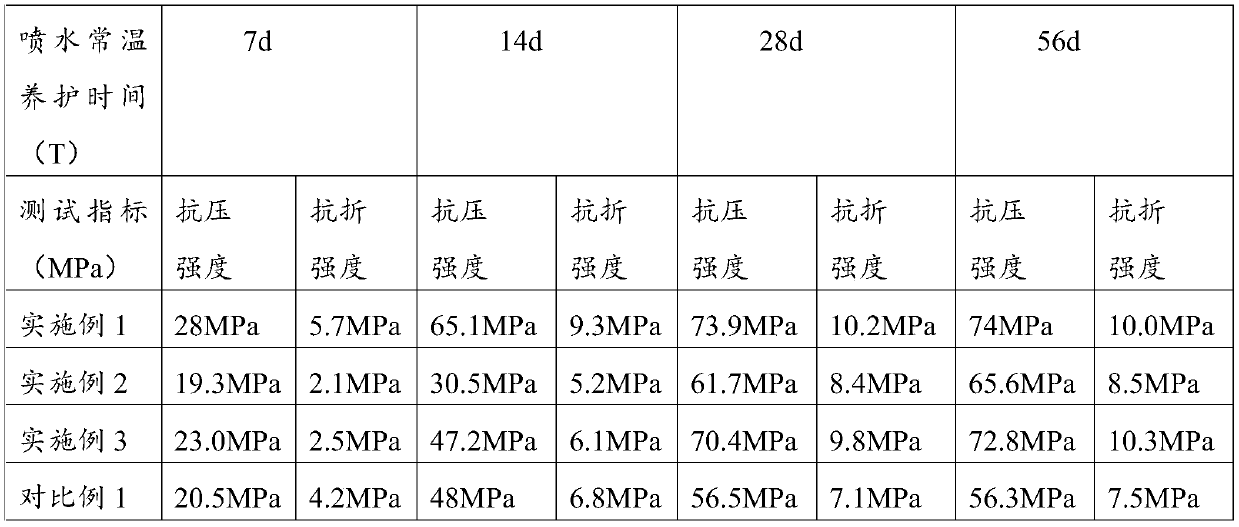

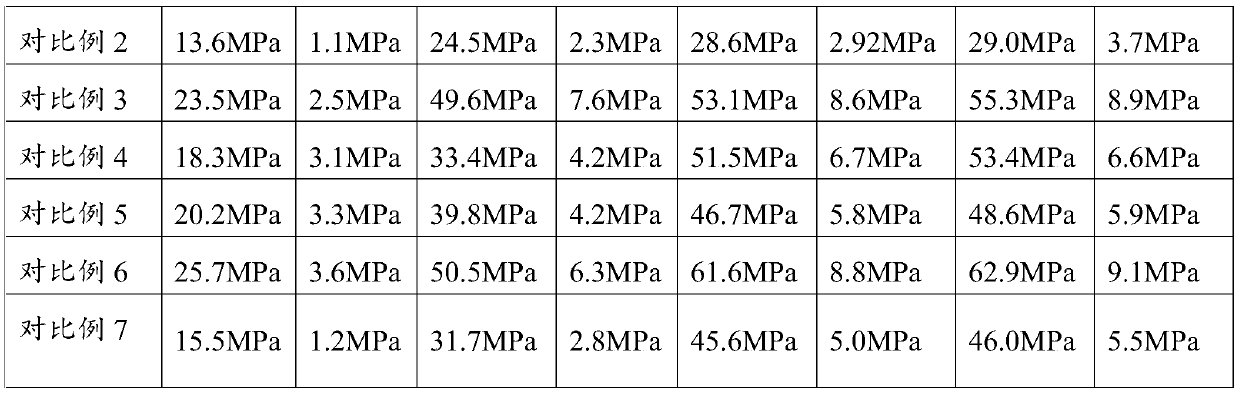

Embodiment 1

[0053] The present embodiment carries out the preparation of graphene geopolymer material, and raw material comprises sludge 0.2kg, activated silica-alumina material calcined kaolin 0.597kg, alkali activator 0.2kg, graphene 0.001kg, tartaric acid 0.0005kg, potassium phosphate 0.0003kg, Naphthalene series water reducer 0.001kg (sodium sulfate content is 10wt%), preparation comprises the following steps:

[0054] 1) Put calcined kaolin into a container, add sludge and mix mechanically at 200rpm for 5min, then add graphene, tartaric acid, potassium phosphate and naphthalene-based water reducer and stir mechanically at 500rpm for 3min, stir well and then add alkali activator , with 100rpm mechanical stirring for 2min to obtain a slurry;

[0055] 2) Pour the slurry into the mold, place it on a shaking table and vibrate for 3 minutes, then place it in a steam curing box for 24 hours of steam curing at 80°C and a relative humidity of 95%, and then spray water at room temperature for ...

Embodiment 2

[0057] This example prepares a graphene geopolymer material, and the difference from Example 1 is that calcined kaolin is replaced by fly ash.

Embodiment 3

[0059] The present embodiment carries out the recycling of graphene geopolymer material, comprises the following steps:

[0060] 1) Putting the graphene geopolymer material of Example 1 into a concrete pulverizer for pulverization, and calcining the graphene geopolymer particles with a particle size of 100 to 2500 meshes to obtain calcined graphene geopolymer materials;

[0061] 2) Return the calcined graphene geopolymer material to the pulverizer, pulverize and sieve, select the powder with a particle size of 1600 mesh, and then use it in combination with calcined kaolin, the mass ratio of calcined graphene geopolymer material to calcined kaolin 1:2, then mixed with sludge, then added graphene, tartaric acid, potassium phosphate and naphthalene-based water reducer, stirred evenly, and then added alkali activator to obtain regeneration slurry;

[0062] 3) Pour the regenerated slurry into the mold, then steam curing, and then spray water at room temperature for curing, use a no...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com