Insulating oil base oil and preparation method thereof, and insulating oil

A technology of insulating oil and base oil, applied in the petroleum industry, processing hydrocarbon oil, hydrocarbon oil treatment products, etc., can solve the problems of unqualified breakdown voltage of main transformer casing oil, high kinematic viscosity, safety accidents, etc., and achieve excellent Oxidation stability, simple preparation process, and improved versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

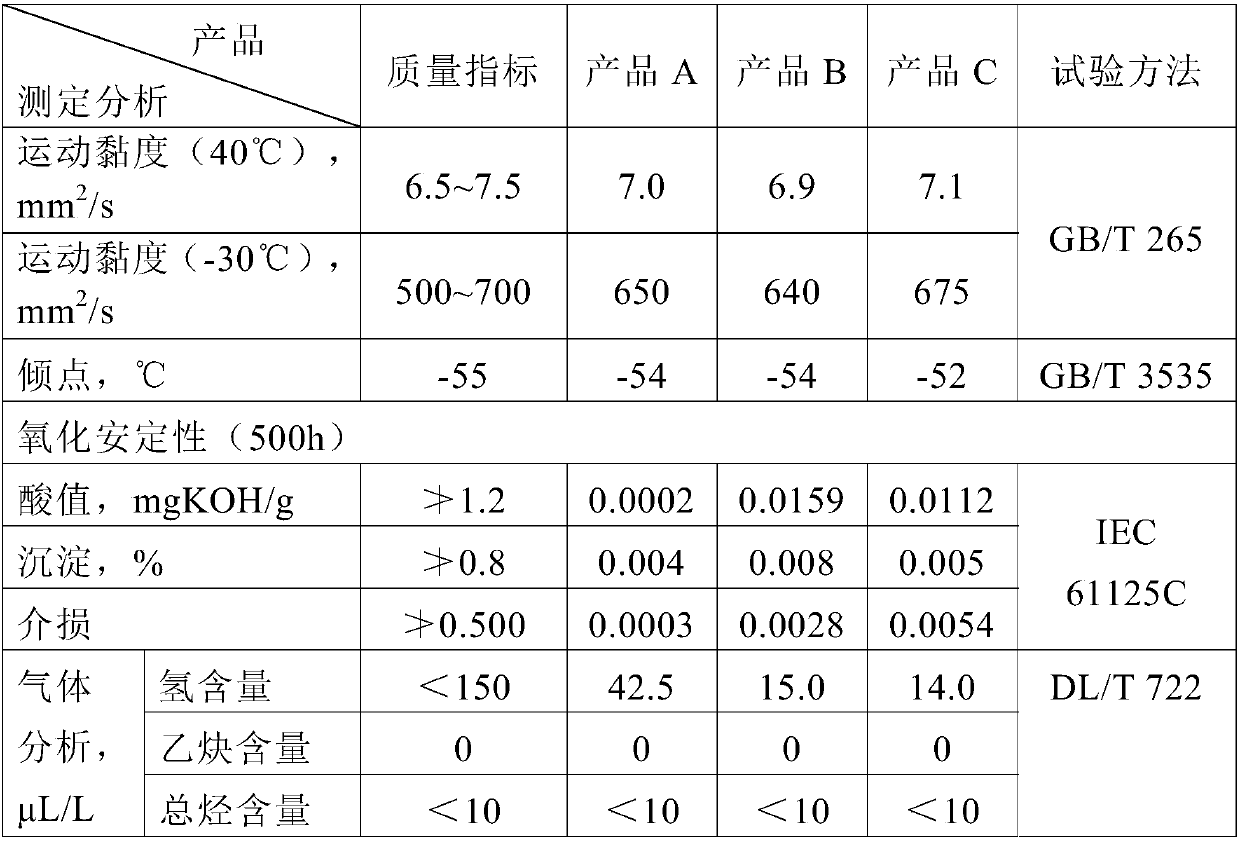

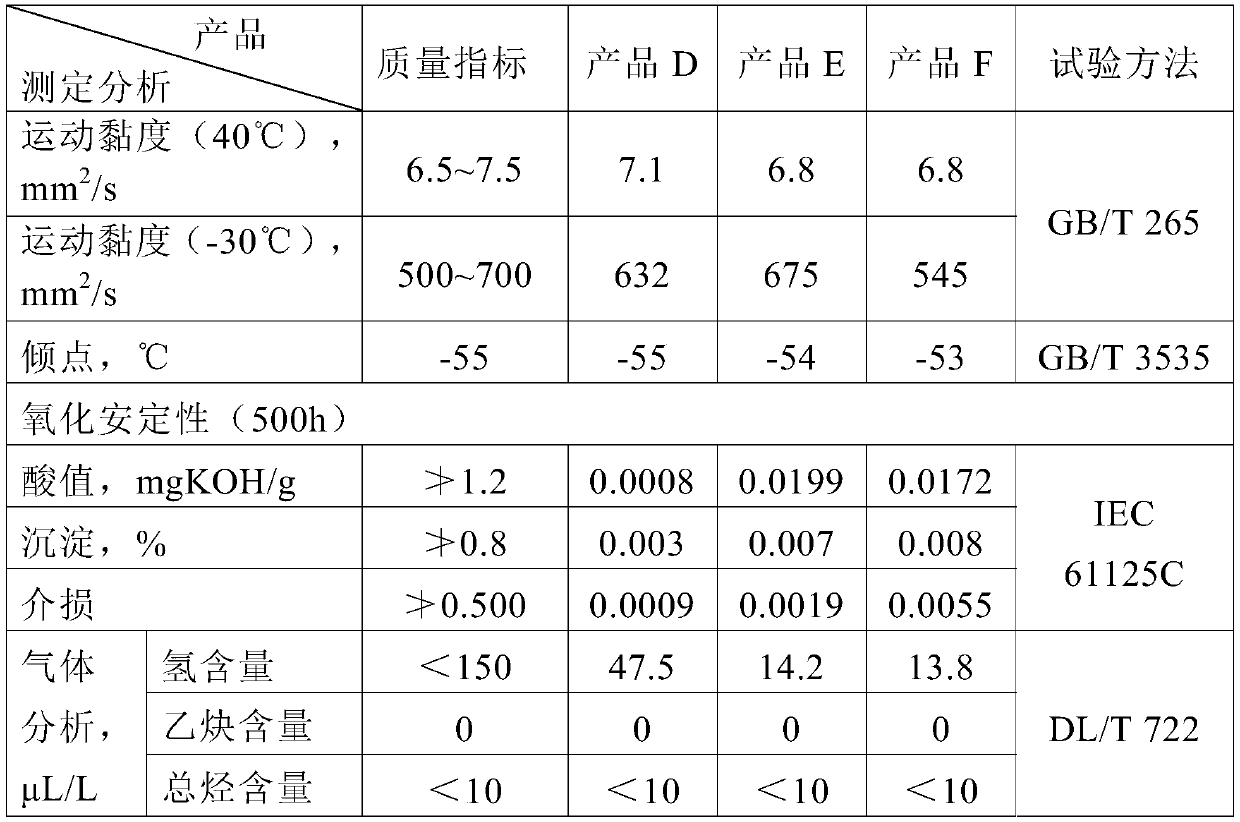

Examples

Embodiment 1

[0059] This embodiment provides a base oil for insulating oil, which includes 70% of the first component, 25% of the second component, and 5% of the third component of synthetic oil benzyltoluene based on the total mass of 100%. . in:

[0060] The first component is prepared by the following steps:

[0061] (1) Hydrofining

[0062] The 280-350°C distillate of the naphthenic feedstock oil described in Table 1 is subjected to hydrotreating to obtain the first refined distillate.

[0063] The conditions for hydrofining are: hydrogen partial pressure 2.0Mpa, reaction temperature 450°C, volumetric space velocity 0.3h -1 , The volume ratio of hydrogen to oil is 2000:1.

[0064] The catalyzer that adopts is nickel-tungsten / amorphous silica-alumina catalyst, accounts for catalyzer weight percentage, and nickel content is 8wt%, and tungsten content is 27wt%, and silica carrier content is 10wt%, and remainder is alumina carrier; The physical parameters are: the average pore diamete...

Embodiment 2

[0082] This embodiment provides a base oil for insulating oil, which includes 75% of the first component, 22% of the second component, and 3% of the third component of synthetic oil benzyltoluene based on the total mass of 100%. . in:

[0083]The first component is prepared by the following steps:

[0084] (1) Hydrofining

[0085] The 280-350°C distillate of the naphthenic feedstock oil described in Table 1 is subjected to hydrotreating to obtain the first refined distillate.

[0086] The conditions of hydrofining are: hydrogen partial pressure 7.0Mpa, reaction temperature 360℃, volume space velocity 1.0h -1 , The volume ratio of hydrogen to oil is 500:1.

[0087] The catalyzer that adopts is nickel-tungsten / amorphous silica-alumina catalyst, accounts for catalyzer weight percentage, nickel content is 10wt%, tungsten content is 25wt%, silica carrier content is 15wt%, remainder is alumina carrier; The physical parameters are: the average pore diameter is The specific sur...

Embodiment 3

[0105] This embodiment provides a method for preparing insulating oil base oil, comprising the following steps:

[0106] 1. Prepare the first component

[0107] (1) Hydrofining

[0108] The 280-350°C distillate of the naphthenic feedstock oil described in Table 1 is subjected to hydrotreating to obtain the first refined distillate.

[0109] The conditions of hydrofining are: hydrogen partial pressure 5.0MPa, reaction temperature 340℃, volume space velocity 0.8h -1 , The volume ratio of hydrogen to oil is 300:1.

[0110] The catalyzer that adopts is nickel-tungsten / amorphous silica-alumina catalyst, accounts for catalyzer weight percentage, nickel content is 5wt%, tungsten content is 28wt%, silica carrier content is 13wt%, balance is alumina; The physical property of catalyst The parameters are: average pore diameter Specific surface area 120cm 2 / g, pore volume 0.3cm 3 / g, strength 28N / mm.

[0111] (2) furfural refining

[0112] The first refined distillate oil is sub...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com