Gas drainage system of service gallery

A technology for auxiliary tunnels and discharge systems, applied in gas discharge, dust prevention, mining equipment and other directions, can solve problems such as hazards to tunnel safe operation, safety accidents, gas accumulation, etc., to eliminate the risk of gas explosion, improve safety, and reduce gas effect of concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

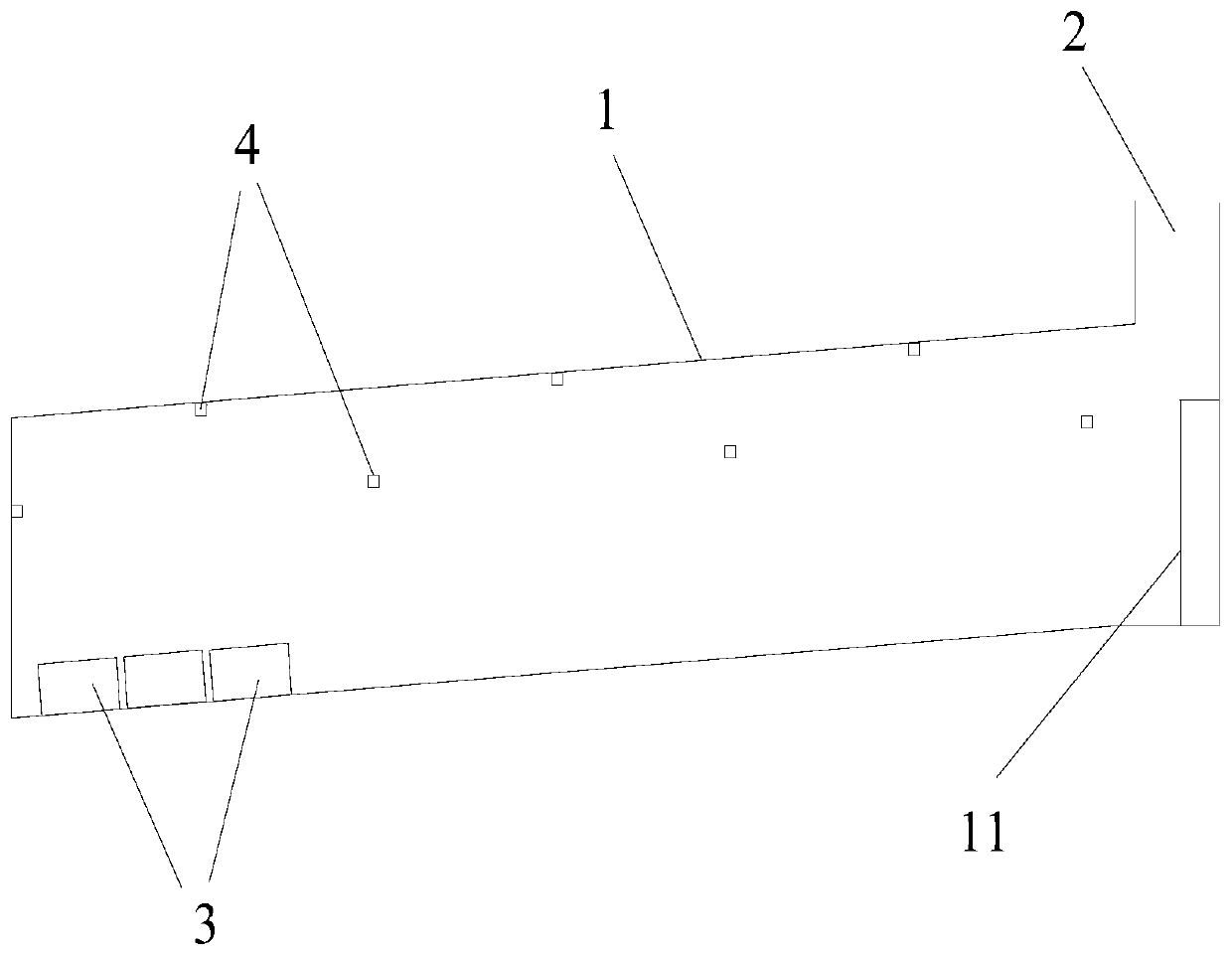

[0040] Such asfigure 1 As shown, the gas discharge system of an auxiliary tunnel according to the present invention includes a ventilation opening 2 connected to the auxiliary tunnel 1, preferably, the ventilation opening 2 is located above the sealing wall 11 of the auxiliary tunnel 1, and the The orientation of the vent 2 is perpendicular to the perennial wind direction at the vent 2, so as to facilitate the discharge of methane gas, and at the same time prevent external air from being poured into the auxiliary tunnel 1 due to the wind direction, and also facilitate the flow of external natural wind to generate negative pressure to suck out all Describe the air in the auxiliary tunnel.

[0041] The size requirement of described vent 2 can be put into storage device 3, and described storage device 3 can store as nitrogen or inert gas or air, promptly as described storage device 3 can be liquid nitrogen tank, high-pressure nitrogen cylinder, inert gas tank , a compressed air t...

Embodiment 2

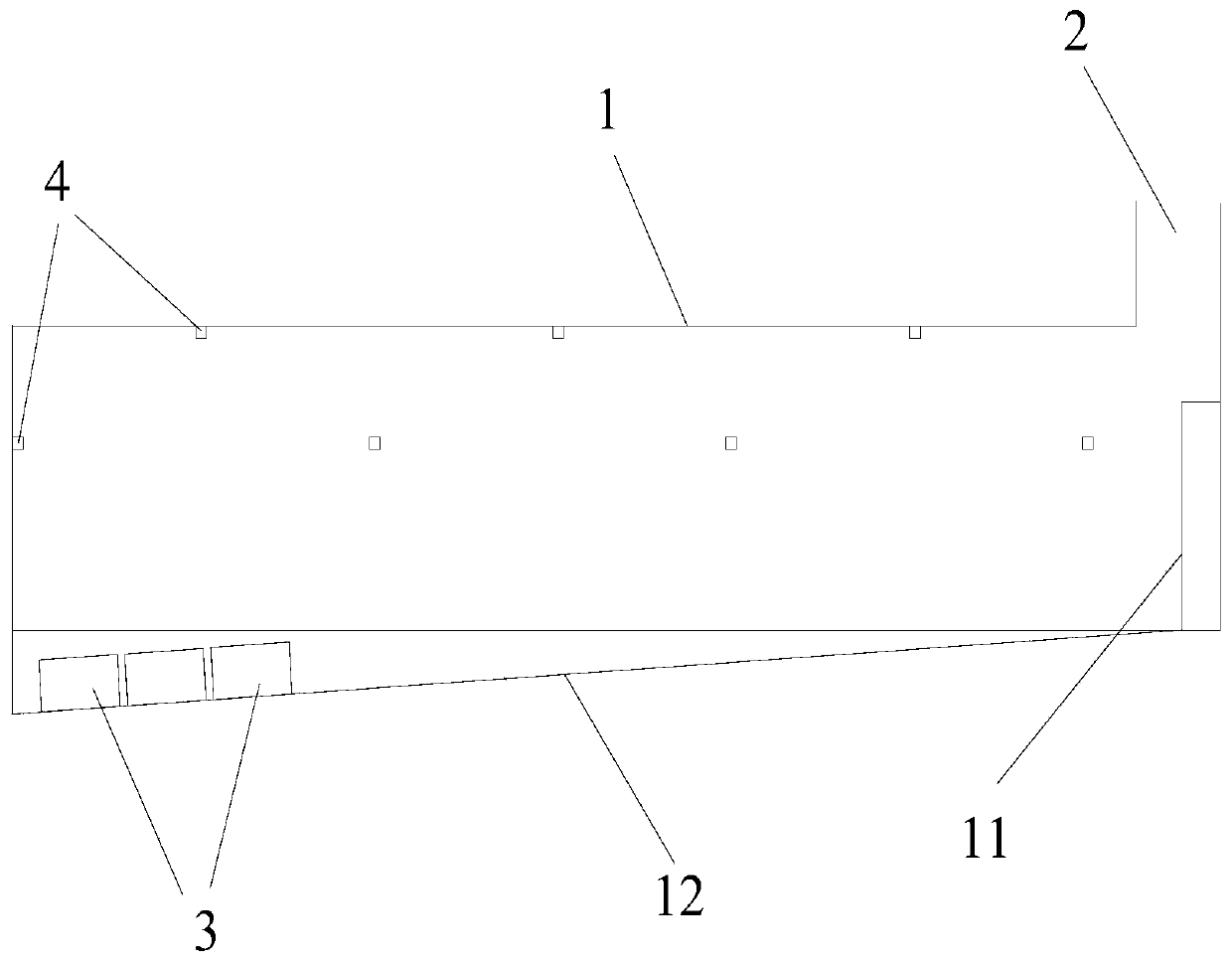

[0047] Such as figure 2 As shown, the gas discharge system of an auxiliary tunnel according to the present invention has the same structure as that of Embodiment 1, the difference is that the auxiliary tunnel 1 is a horizontal hole or other forms of parallel pilot pits, or There are many sundries on the ground of the tunnel, and a chute 12 is arranged in the auxiliary tunnel 1, and the chute 12 is provided throughout the length, and the chute 12 is arranged below the vent 2, and the tail end of the chute 12 Lower than the end of the chute 12 close to the vent 2, the storage device 3 slides to the tail end of the auxiliary tunnel 1 through the chute 12, which is conducive to releasing gas at the end of the auxiliary tunnel 1 and improving Efficiency and effectiveness of gas emissions.

Embodiment 3

[0049] A gas discharge method for an auxiliary tunnel according to the present invention, comprising applying a gas discharge system for an auxiliary tunnel as described in any one of Embodiments 1-2, comprising the following steps:

[0050] a. The gas concentration acquisition part 4 collects the gas concentration data in the auxiliary tunnel 1, and when the gas concentration data continues to be greater than or equal to the first preset threshold within the first preset period, the control system controls the valve of the storage device 3 to open ;

[0051] b. After the storage device 3 releases gas, when the gas concentration data continues to be less than the second preset threshold within the second preset period, the control system controls the valve of the storage device 3 to close;

[0052] c. Repeat steps a-b.

[0053] Because the main components of gas gas are alkanes, among which methane accounts for the vast majority, therefore, if the gas concentration collection...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com