Integrated circuit structure and forming method thereof

A technology of integrated circuit and epoxy resin, which is applied in circuits, electrical components, electric solid devices, etc., can solve the problems of insufficient waterproof and flame-retardant performance, lack of flame-retardant and waterproof materials, and reduce the volume of circuits, so as to avoid cracking of circuit boards and Damage, Overall Toughness Improvement, Stability Improvement Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

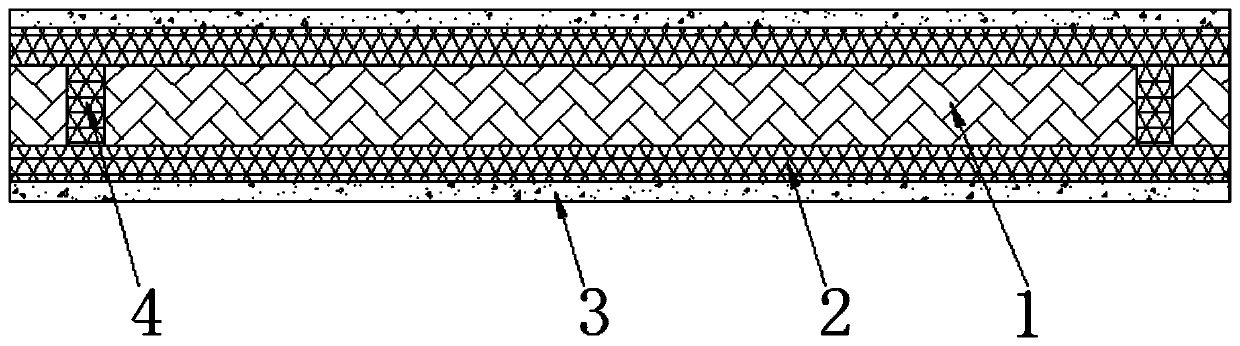

Image

Examples

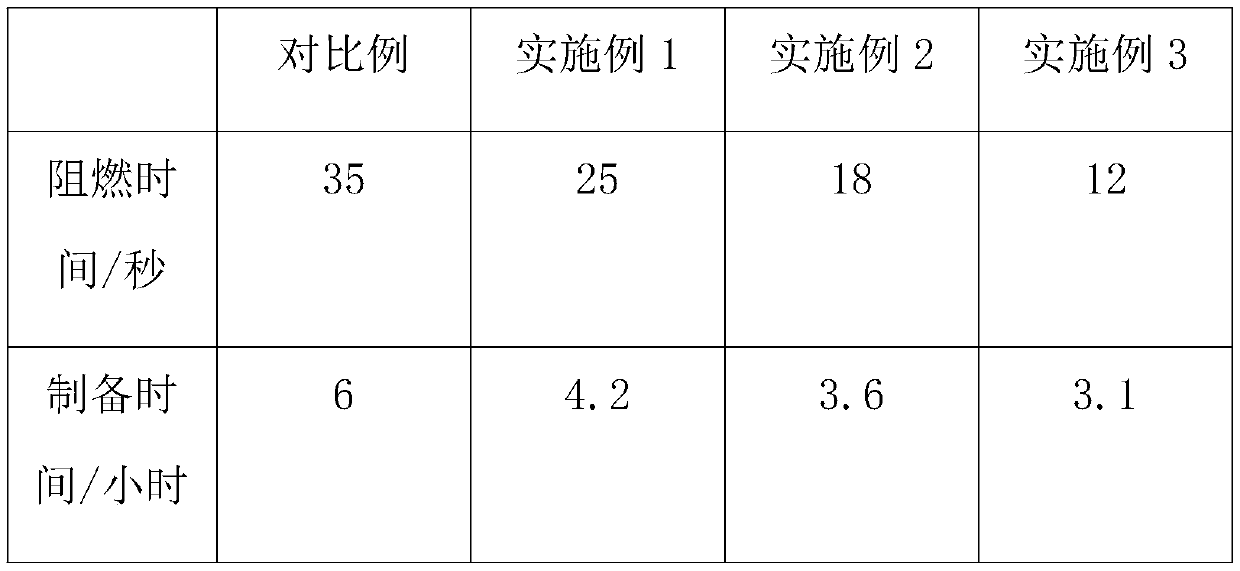

Embodiment 1

[0037] Step 1: Prepare preparation tools: Take out all the production tools involved in the preparation work, wipe them with a clean soft cloth, and place them for use;

[0038] Step 2: Organize and summarize the reaction materials: After taking out all the reaction materials involved in the preparation and weighing, put them on the special preparation table according to the type, and cover and seal them, and then place them for use;

[0039] Step 3: Add the reaction material for the first time: Pour the weighed basic resin (80 parts of cycloaliphatic modified epoxy resin, 20 parts of olfactory epoxy resin, 30 parts of novolac resin) into the reaction crucible, and then slowly heat up To 150 degrees Celsius, then add 20 parts of aromatic polyamide, 10 parts of silica, 15 parts of alumina, 10 parts of aluminum nitride, 12 parts of calcium silicate, 12 parts of polymethylsiloxane, and heat slowly after adding To 260 degrees Celsius, then keep it warm for 5 minutes;

[0040] Step 4: Ad...

Embodiment 2

[0044] Step 1: Prepare preparation tools: Take out all the production tools involved in the preparation work, wipe them with a clean soft cloth, and place them for use;

[0045] Step 2: Organize and summarize the reaction materials: After taking out all the reaction materials involved in the preparation and weighing, put them on the special preparation table according to the type, and cover and seal them, and then place them for use;

[0046] Step 3: Add the reaction material for the first time: Pour the weighed basic resin (100 parts of cycloaliphatic modified epoxy resin, 30 parts of olfactory epoxy resin, and 50 parts of novolac resin) into the reaction crucible, and then slowly heat up To 150 degrees Celsius, then add 45 parts of aromatic polyamide, 15 parts of silica, 25 parts of alumina, 15 parts of aluminum nitride, 18 parts of calcium silicate, 15 parts of polymethylsiloxane, and slowly heat after adding To 260 degrees Celsius, then keep it warm for 5 minutes;

[0047] Step ...

Embodiment 3

[0051] Step 1: Prepare preparation tools: Take out all the production tools involved in the preparation work, wipe them with a clean soft cloth, and place them for use;

[0052] Step 2: Organize and summarize the reaction materials: After taking out all the reaction materials involved in the preparation and weighing, put them on the special preparation table according to the type, and cover and seal them, and then place them for use;

[0053] Step 3: Add the reaction material for the first time: Pour the weighed basic resin (150 parts of cycloaliphatic modified epoxy resin, 40 parts of olfactory epoxy resin, and 80 parts of novolac resin) into the reaction crucible, and then slowly heat up To 150 degrees Celsius, then add 70 parts of aromatic polyamide, 20 parts of silica, 30 parts of alumina, 20 parts of aluminum nitride, 22 parts of calcium silicate, and 18 parts of polymethylsiloxane. After the addition, heat slowly To 260 degrees Celsius, then keep it warm for 5 minutes;

[0054...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com