Flame-retardant EPS foam material as well as preparation method and application thereof

A foam material and flame-retardant technology, which is applied in the field of flame-retardant EPS foam material and its preparation, can solve problems such as droplet dripping, threat to life and property safety, and impact on the application of polystyrene, so as to increase flame retardancy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0040] The preparation of preparation example 1 melamine resin prepolymer

[0041] Add 20 mL of deionized water into the three-necked flask equipped with a reflux condensing device, add 10 g of melamine and 25 mL of formaldehyde with a mass concentration of 37% into the three-necked flask, stir and mix evenly, adjust the pH of the system to 8.0 with triethanolamine, and heat up to 70 ℃, stir at 200r / min until the mixed solution is completely transparent, keep it warm for 30 minutes, and cool down to room temperature to prepare a transparent and viscous melamine resin prepolymer solution for later use.

preparation example 2

[0042] Preparation Example 2 Preparation of Surface Modified Microencapsulated Flame Retardant

[0043] S1: Stir and disperse 10g of magnesium hydroxide (MH) and 5g of aluminum hydroxide (ATH) into 10g of bis(2-ethylhexyl) phosphate, stir thoroughly for 3-5min until the dispersion is uniform, and then add polyborosilicate Oxygen 10g and triphenyl phosphate (TPP) 5g, stir rapidly for about 1min to form a mixed flame retardant system;

[0044] S2: Slowly add 15-25 g of the melamine resin prepolymer obtained in Preparation Example 1 dropwise to the mixed flame retardant system prepared in step S1, stir rapidly, adjust the pH of the system to 5.4, raise the temperature to 80° C., and keep it warm for 2 hours;

[0045] S3: Stop stirring, adjust the pH of the system to 7.0, slowly lower to room temperature, filter, wash with deionized water for 3 times, and dry in a 30°C drying oven for 4 hours to obtain a microencapsulated flame retardant;

[0046] S4: Put 10mL of hexamethyldisila...

Embodiment 1

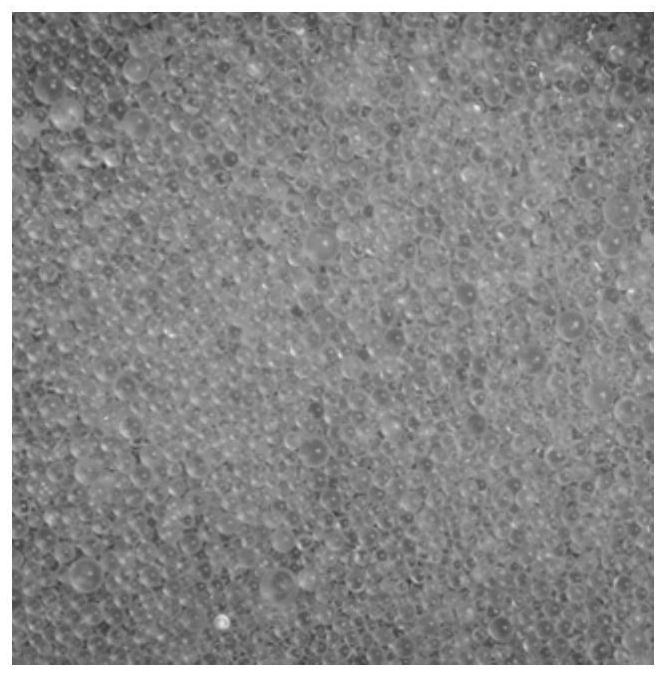

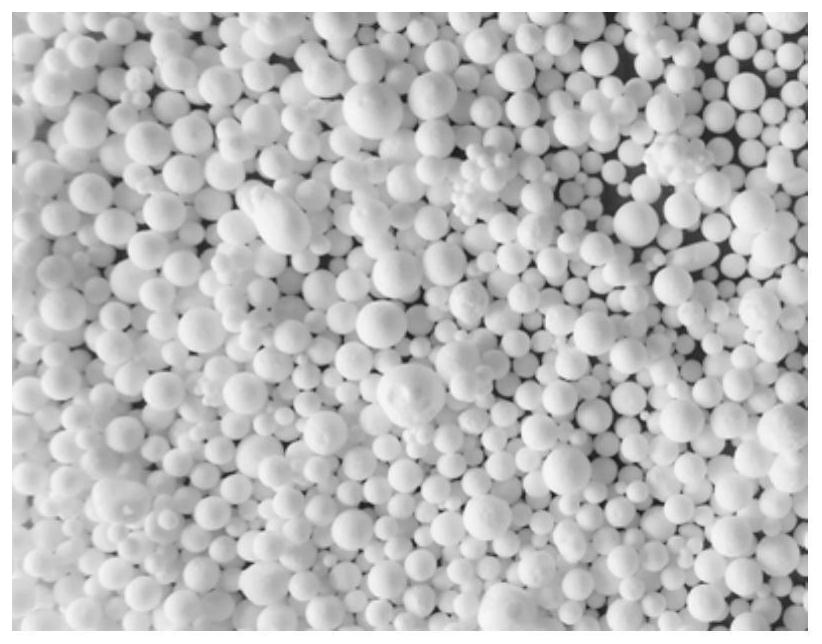

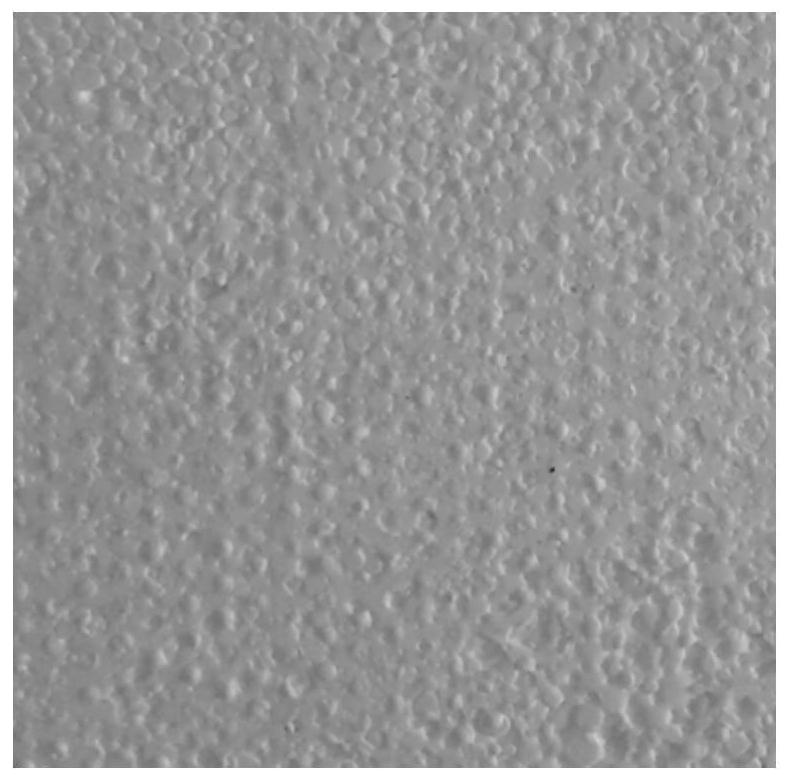

[0051] The preparation of embodiment 1 EPS foam board

[0052] S1: Add 120mL of deionized water into a 5L high-temperature and high-pressure reactor, turn on the agitator, add 0.5g of active calcium phosphate and 0.5g of calcium carbonate as dispersants, add 0.3g of sodium dodecylbenzenesulfonate, and stir for 5 minutes After adjusting the pH of the system to 8.0, add 100 g of styrene monomer, stir to form milky white droplets, slowly add 6 g of the surface-modified microencapsulated flame retardant prepared in Preparation Example 2, and then add dibenzoyl peroxide and dibenzoyl peroxide. 0.5g of cumene respectively, heat up to 90°C, start timing, and react at a constant temperature of 90±0.5°C for 6 hours;

[0053] S2: Add 6 g of n-pentane to the reaction system, raise the temperature to 120°C, and control the reaction at a constant temperature of 120±0.5°C for 3 hours;

[0054] S3: Cool to room temperature, discharge, filter, wash with deionized water three times, and dry a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Relative viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com