Multistage carbon nanostructure anchored Ni-N4 monatomic catalyst as well as preparation method and application thereof

A carbon nanostructure and catalyst technology, applied in structural parts, electrical components, battery electrodes, etc., can solve the problems of difficult control of particle size on the surface of catalysts, uneven particle distribution, low atom utilization, etc., to achieve easy promotion and The effect of large-scale production, simple and effective preparation process, and excellent catalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035]Mix 570mg of EMIM-dca with 100mg of nickel nitrate and stir magnetically at room temperature (25°C) for 12h to form a homogeneous blue mixture; place the mixture in a tube furnace and pyrolyze it for 2h at 1000°C under an argon atmosphere (heating rate is 5°C / min), cooled to room temperature to obtain a black solid; use sulfuric acid (2mol / L, 80mL) to acidify the gained black solid at 80°C for 24h to remove the active metal Ni and its oxides in the material; The acid-washed material was centrifuged to collect the solid, washed with water (until the pH value of the washing liquid reached 7) and dried (4h) in a vacuum drying oven (80°C); the dried product was subjected to secondary high-temperature pyrolysis , under an argon atmosphere at 1000°C, pyrolyze for 2h (heating rate is 5°C / min), and cool to room temperature to obtain NiN 4 -C single atom catalyst.

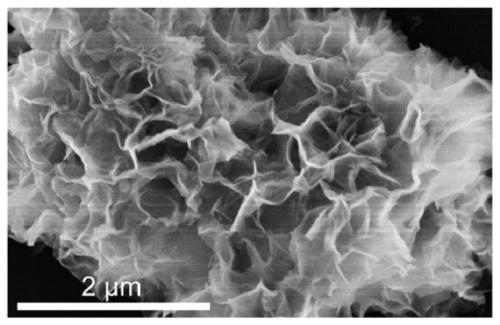

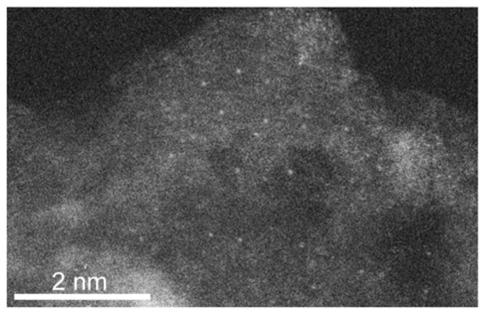

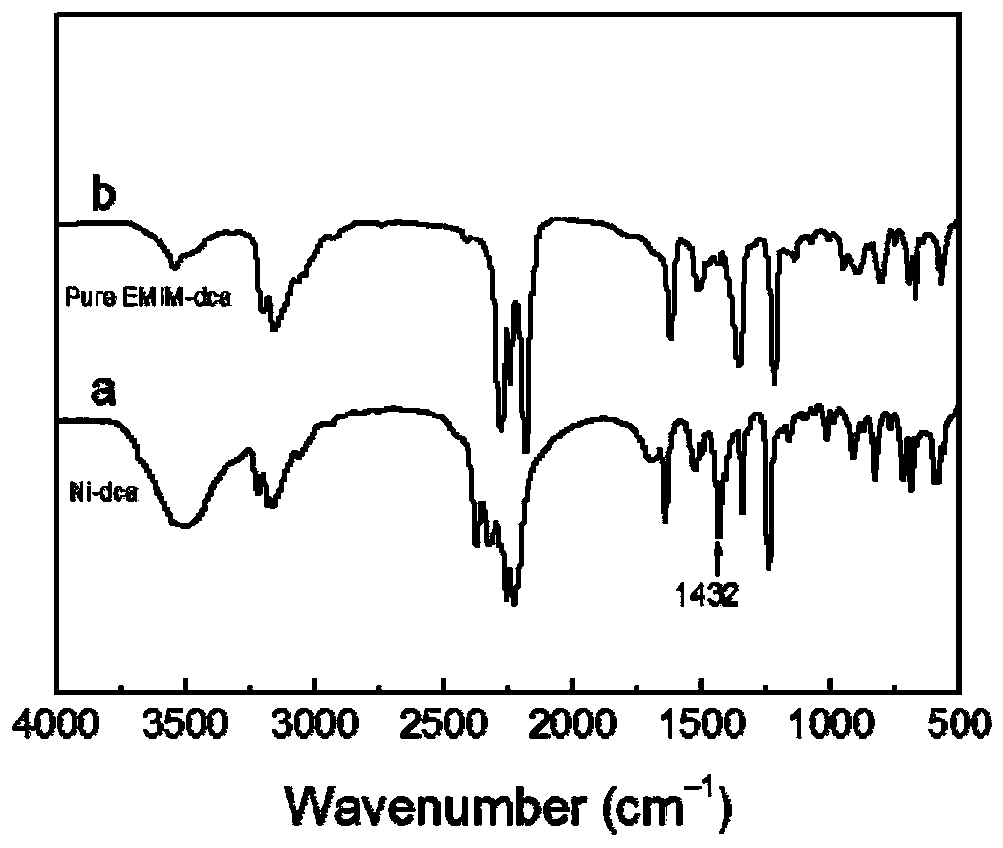

[0036] The NiN of embodiment 1 preparation-C single-atom catalyst, scanning electron microscope result (SEM) such ...

Embodiment 2

[0038] Mix 570mg of EMIM-dca with 100mg of nickel nitrate and stir magnetically at room temperature (20°C) for 24h to form a homogeneous blue mixture; place the mixture in a tube furnace and pyrolyze it for 4h at 700°C under an argon atmosphere (heating rate is 5°C / min), cooled to room temperature to obtain a black solid; hydrochloric acid (6mol / L, 80mL) was used to acidify the gained black solid at 100°C for 12h to remove the active metal Ni and its oxides in the material; The acid-washed material was centrifuged, washed (until the pH value of the washing liquid reached 7) and dried (2h) in a vacuum oven (100°C); the dried product was subjected to secondary pyrolysis at 700 Under an argon atmosphere at ℃, pyrolyze for 4h (heating rate is 5℃ / min), and cool to room temperature to obtain NiN 4 -C single atom catalyst.

Embodiment 3

[0040] Mix 570mg EMIM-dca with 100mg nickel acetate, and stir magnetically at room temperature (25°C) for 12h to form a homogeneous blue mixture; place the mixture in a tube furnace and pyrolyze it for 3h at 900°C under an argon atmosphere (heating rate is 5°C / min), cooled to room temperature to obtain a black solid; use sulfuric acid (4mol / L, 80mL) to acidify the gained black solid at 90°C for 20h to remove the active metal Ni and its oxides in the material; The acid-washed material was centrifuged, washed (until the pH value of the washing liquid reached 7) and dried (3h) in a vacuum oven (90° C.); the dried product was subjected to secondary pyrolysis at 900 Under an argon atmosphere at ℃, pyrolyze for 3h (heating rate is 5℃ / min), and cool to room temperature to obtain NiN 4 -C single atom catalyst.

PUM

| Property | Measurement | Unit |

|---|---|---|

| current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com