Multi-element doped platinum-based catalyst and preparation method and application thereof

A catalyst and doping technology, which is applied in the multi-doped platinum-based catalyst and its preparation field, can solve the problems of high price, low storage capacity of Pt metal, and easy poisoning, so as to improve utilization rate, improve durability, The effect of improving catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

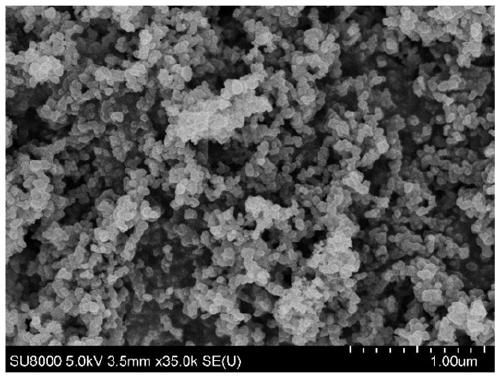

[0060] The preparation method of the multiple-doped platinum-based catalyst:

[0061] (I) Weigh 0.05g Ketjen black carbon powder and place it in a reaction container, add 20mL water to it, then place the mixed solution in an ultrasonic pulverizer homogenizer to disperse evenly, and continue ultrasonication for 10min to obtain Ketjen black carbon powder of the dispersion. Then continue to feed nitrogen into it for 30min, then proceed to the next step;

[0062] (II) Take 400 μL of chloroplatinic acid solution with a platinum element content of 0.1 g / mL, 50 μL of a ferric chloride solution with an iron content of 0.1 g / mL, and 50 μL of a cobalt chloride solution with a Co content of 0.1 g / mL in the In the dispersion liquid of the Ketjen black carbon powder prepared in the step (I), under the protection of nitrogen, continue to stir for 1h to obtain a mixed solution, so that the ions are fully adsorbed to the surface of the Ketjen black carbon powder;

[0063] (Ⅲ) Weigh 0.1 g of...

Embodiment 2

[0080] The preparation method of the multiple-doped platinum-based catalyst:

[0081] (I) Weigh 0.048g of Cabot carbon powder (Vulcan XC-72) and place it in a reaction vessel, add 15mL of water to it, then place the mixed solution in an ultrasonic homogenizer to disperse evenly, and continue ultrasonication for 60min to obtain Dispersion of Cabot toner, then continue to pass argon gas into it for 45 minutes, and then proceed to the next step;

[0082] (II) Take 500 μL of potassium tetrachloroplatinate solution with a platinum content of 0.1 g / mL, 10 μL of a nickel chloride solution with a nickel content of 0.1 g / mL, and 10 μL of a copper solution with a copper content of 0.1 g / mL. Copper chloride solution is added in the dispersion liquid of the prepared Cabot carbon powder of step (I), under argon protection, continue to stir 6h, obtain mixed solution, make ion fully adsorb on the surface of Cabot carbon powder;

[0083] (Ⅲ) Weigh 0.3 g of hydroxylamine hydrochloride, and un...

Embodiment 3

[0087] The preparation method of the multiple-doped platinum-based catalyst:

[0088] (I) Weigh 0.049g of carbon nanotubes and place them in a reaction vessel, add 20mL of water therein, then place the mixed solution in an ultrasonic homogenizer to disperse evenly, and continue ultrasonication for 30min to obtain a dispersion of carbon nanotubes, then Continuously inject helium into it for 30 minutes, and then proceed to the next step;

[0089] (II) Take 450 μL of potassium hexachloroplatinate solution with a platinum content of 0.1 g / mL, 30 μL of a cobalt nitrate solution with a Co content of 0.1 g / mL, and 30 μL of a sulfur solution with a Mo content of 0.1 g / mL. The ammonium molybdate solution is added to the dispersion of carbon nanotubes prepared in step (I), and under the protection of helium, the stirring is continued for 3h to obtain a mixed solution, so that the ions are fully adsorbed to the surface of the carbon nanotubes;

[0090] (Ⅲ) Weigh 0.15 g of potassium boro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Current density | aaaaa | aaaaa |

| Peak power density | aaaaa | aaaaa |

| Peak power density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com