Production method of fiber-containing ruminant feed and feed produced by production method

A production method and ruminant feed technology, which is applied in the field of ruminant feed processing, can solve the problems of quality reduction, price reduction, and darkening of dried distiller's grains, and achieve the effects of improved degradation rate, good digestion, and high nutritional value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

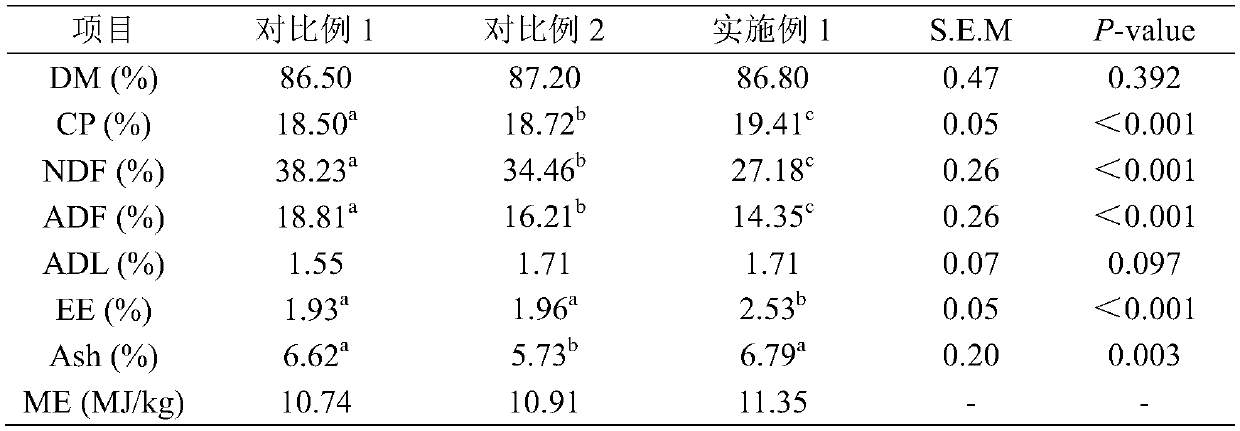

[0080] With straw / liquid alcohol industrial by-product (moisture content is 70wt%) / DDGS / sprayed corn bran / cotton meal / corn germ meal / corn / premix / salt / calcium oxide / calcium hydrogen phosphate=28 / 12 / 14 / 5 / 6 / 20 / 11 / 2 / 1 / 0.6 / 0.4 dry matter weight ratio (i.e. dry weight ratio) Weigh corn stalks, alkali, liquid alcohol industrial by-products and the above-mentioned auxiliary materials, and perform the following operations to repeat Formulated as a full price compounded ruminant feed:

[0081] 1) Add liquid alcohol industrial by-products (the water content of the final mixture is 8.4wt%) to the corn stalks that are crushed into 1-2cm length in advance, and then place the steam explosion tank (the working pressure range of this equipment is 0.1-3.0 MPa), steam explosion pretreatment at a temperature of 150°C and a pressure of 0.48MPa for 25 minutes, and then all the pretreated materials were sprayed out to obtain steam explosion products;

Embodiment 2

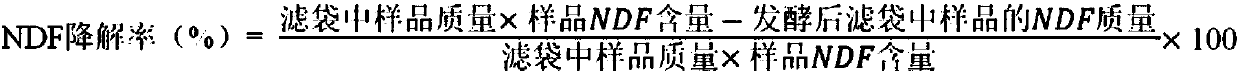

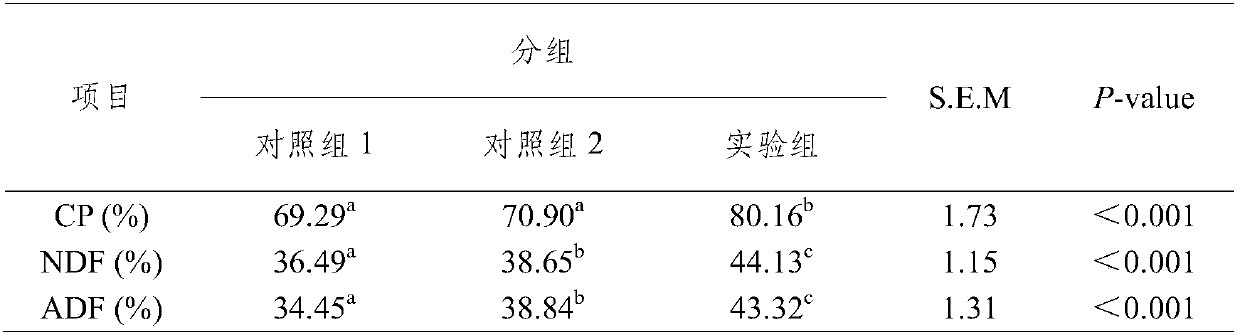

[0093] The impact of the different treatments of embodiment 2 on the degradation rate of feed

[0094] Wheat straw is crushed to a length of 1-2 cm, mixed with liquid alcohol industrial by-products (water content 70wt%) at a dry weight ratio of 7:3, and water is added thereto until the water content of the final mixture is 40wt% , followed by steam explosion pretreatment, steam explosion pretreatment at a temperature of 160°C and a pressure of 0.62MPa for 25 minutes, and then all the pretreated materials were sprayed out, and the dry weight ratio of adding and wheat straw was 1:46.67 The calcium oxide was neutralized, and then the feed obtained after drying at 65°C was used as the experimental group. In addition, the feed obtained with the same operations and materials as the experimental group except that no steam explosion pretreatment was carried out was used as the control group 1; the feed obtained with the same operations and materials as the experimental group except fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com