Catalyst for room-temperature catalytic oxidation of formaldehyde and preparation method thereof

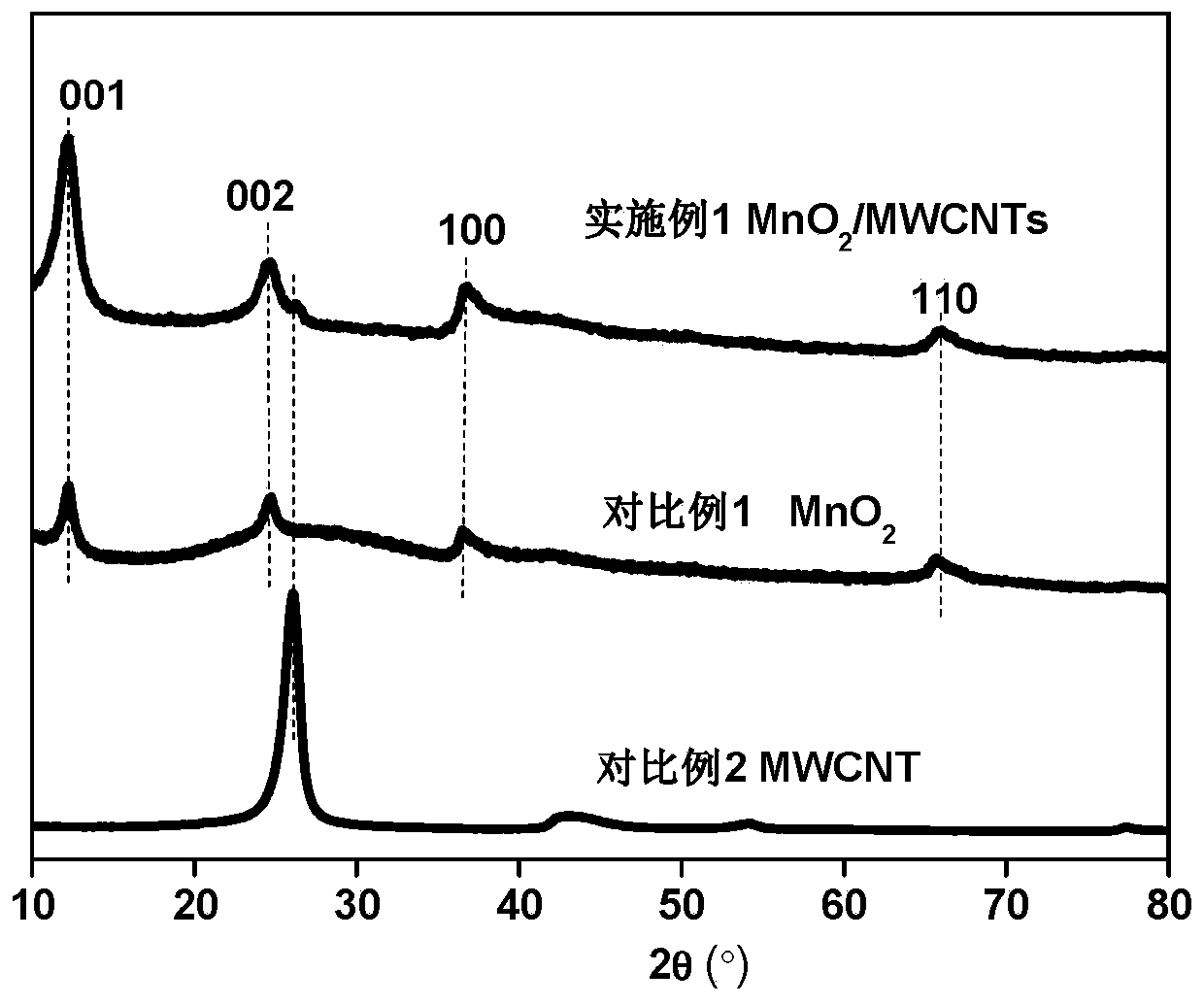

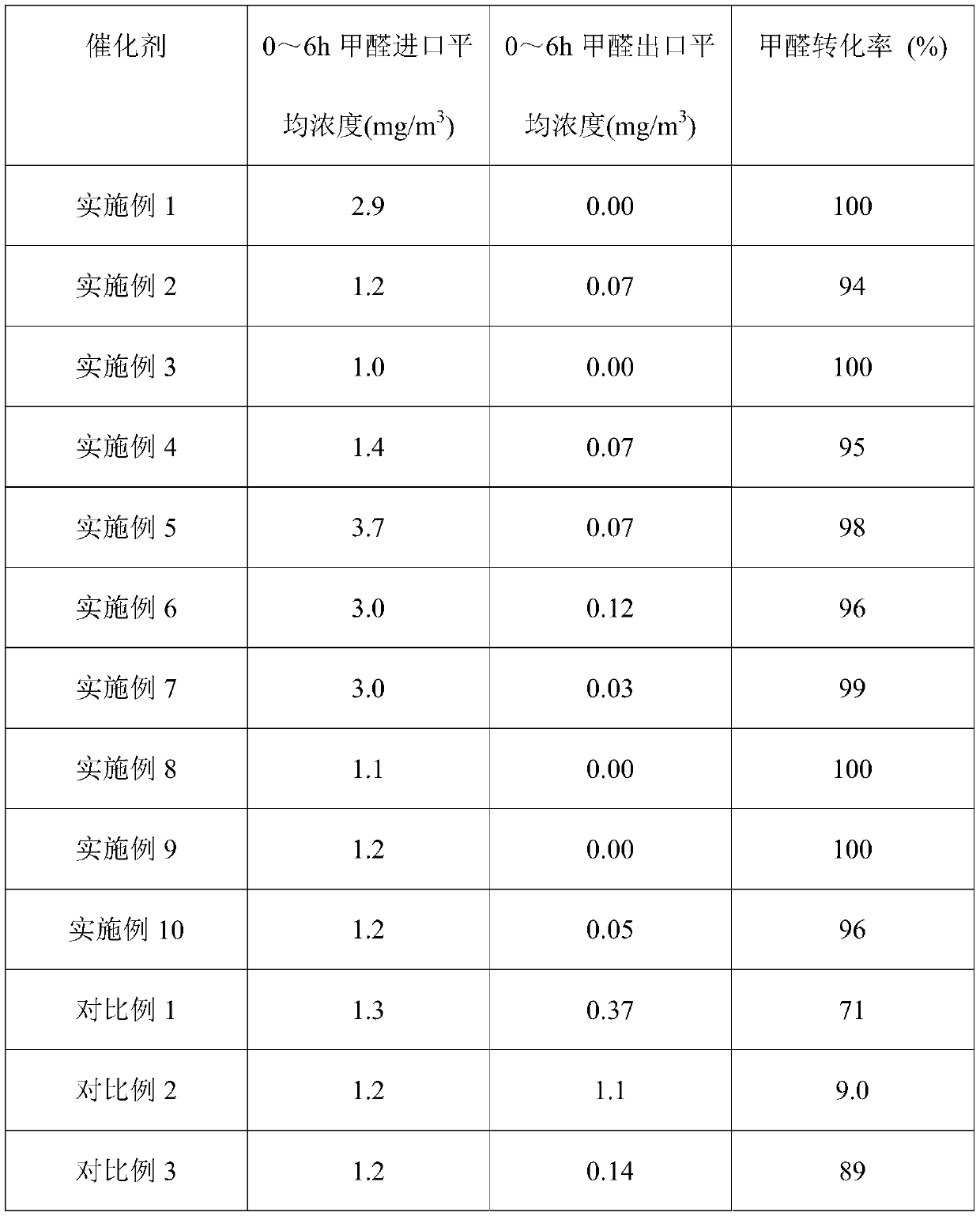

A catalytic oxidation and catalyst technology, applied in the direction of physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, etc., can solve the problem that formaldehyde cannot be removed at room temperature, and achieve improved electronic performance. The effects of transmission, activity improvement, and catalytic oxidation activity improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

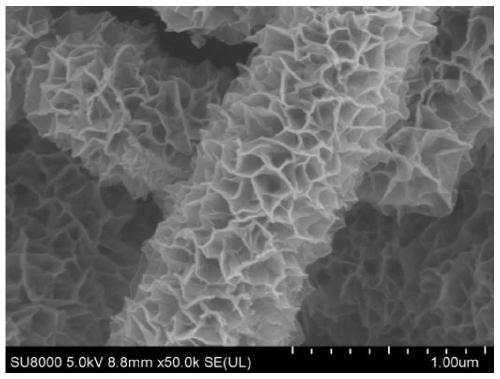

[0035] A preparation method of a catalyst for catalytic oxidation of formaldehyde at normal temperature, comprising the steps of:

[0036] S1. Dissolve the multi-walled carbon nanotubes in nitric acid solution, the pH of the reaction solution is 3, heat and reflux in a water bath at 50°C for 12 hours under constant stirring, cool, filter, and wash to the pH of the filtrate The value is neutral, and the acidified multi-walled carbon nanotubes MWCNTs were obtained by vacuum drying at 120°C for 12 hours;

[0037] S2. Dissolve the acidified multi-walled carbon nanotubes prepared in step S1 in water, ultrasonically treat for 2h, add potassium permanganate, the mass ratio of acidified multi-walled carbon nanotubes and potassium permanganate is 1:12, stir for 4h, The stirring speed is 350r / min, react in a hydrothermal synthesis reactor at 120°C for 6h, after the reaction is completed, cool, wash and filter repeatedly until the pH value of the filtrate reaches neutral, and dry at 100°...

Embodiment 2

[0039] A preparation method of a catalyst for catalytic oxidation of formaldehyde at normal temperature, comprising the steps of:

[0040] S1. Dissolve the multi-walled carbon nanotubes in nitric acid solution, the pH of the reaction solution is 3, heat and reflux in a water bath at 50°C for 12 hours under constant stirring, cool, filter, and wash to the pH of the filtrate The value is neutral, and vacuum-dried at 120°C for 12 hours to obtain acidified multi-walled carbon nanotubes;

[0041] S2. Dissolve the acidified multi-walled carbon nanotubes prepared in step S1 in water, ultrasonically treat for 2h, add potassium permanganate, the mass ratio of acidified multi-walled carbon nanotubes and potassium permanganate is 1:3, stir for 4h, The stirring speed is 350r / min, react in a hydrothermal synthesis reactor at 150°C for 6h, after the reaction is completed, cool, wash and filter repeatedly until the pH value of the filtrate is neutral, and then dry at 100°C for 12h to obtain ...

Embodiment 3

[0043] A preparation method of a catalyst for catalytic oxidation of formaldehyde at normal temperature, comprising the steps of:

[0044] S1. Dissolve the multi-walled carbon nanotubes in nitric acid solution, the pH of the reaction solution is 3, heat and reflux in a water bath at 50°C for 12 hours under constant stirring, cool, filter, and wash to the pH of the filtrate The value is neutral, and vacuum-dried at 120°C for 12 hours to obtain acidified multi-walled carbon nanotubes;

[0045] S2. Dissolve the acidified multi-walled carbon nanotubes prepared in step S1 in water, ultrasonically treat for 2h, add potassium permanganate, the mass ratio of acidified multi-walled carbon nanotubes and potassium permanganate is 1:20, stir for 4h, The stirring speed is 350r / min, react in a hydrothermal synthesis reactor at 150°C for 6h, after the reaction is completed, cool, wash and filter repeatedly until the pH value of the filtrate is neutral, and then dry at 100°C for 12h to obtain t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com