Magnetic Fe2O3/BN composite material as well as preparation method and application thereof

A composite material, fe2o3 technology, applied in chemical instruments and methods, water/sludge/sewage treatment, water/sewage treatment, etc., to achieve good removal effect, reduce loss and promote separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

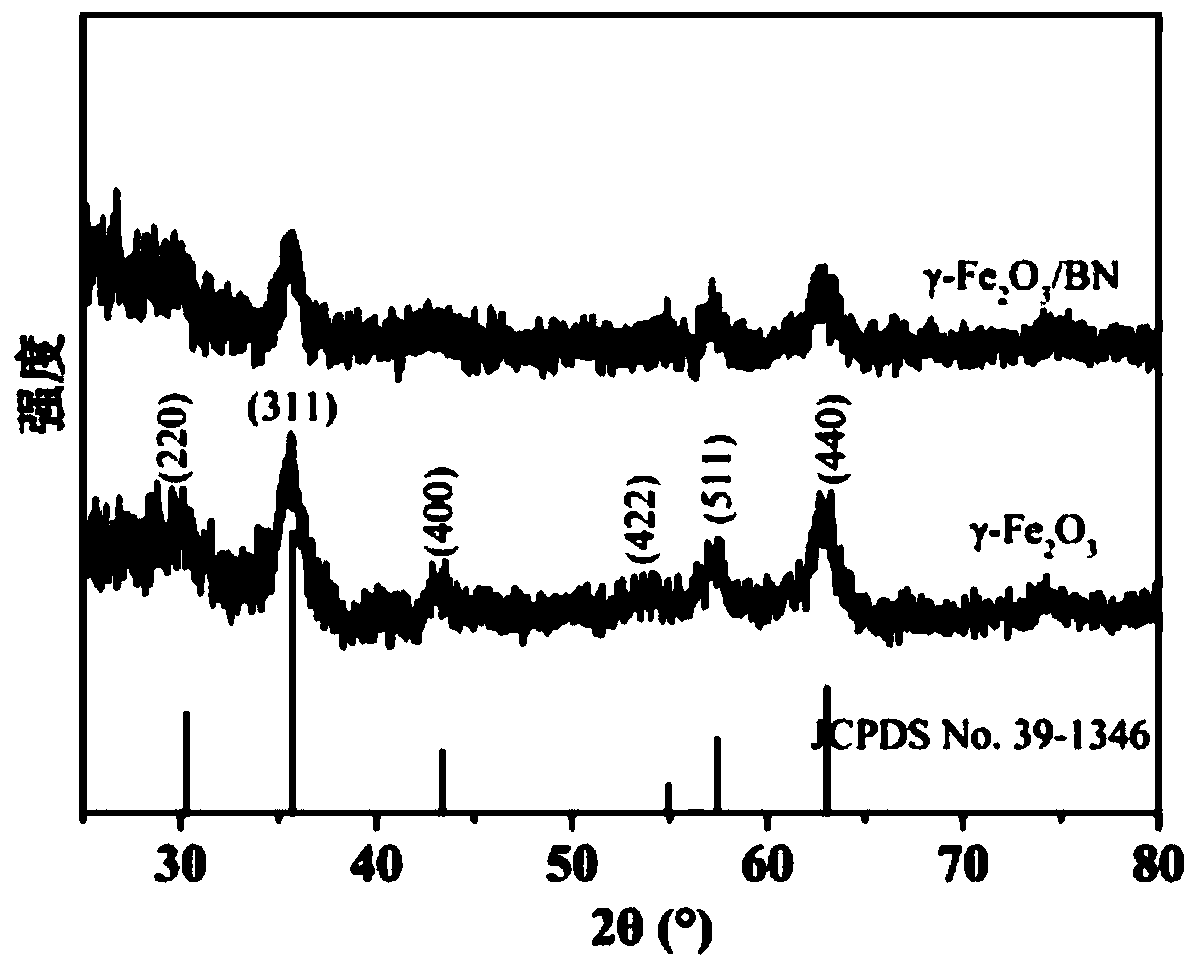

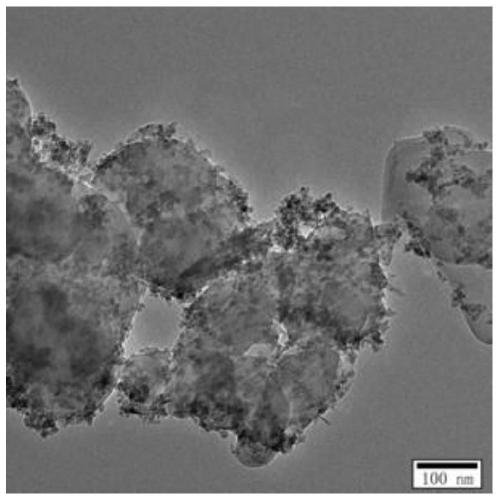

[0030] Ultrasonically disperse 0.026 g ferrous chloride tetrahydrate, 0.108 g ferric chloride hexahydrate and 7.0 mg BN in 80 mL deionized water, heat to 70 °C in an oil bath, add 4 mL ammonia solution, and react for 30 min. After washing with ion water and ethanol, it is recovered by magnet, and then dried to obtain magnetic Fe 2 o 3 / BN composites.

[0031] 10 mg of prepared magnetic Fe 2 o 3 The / BN composite material was put into a photochemical reaction apparatus for photocatalytic degradation test, and the total removal rate of tetracycline by the composite material reached 44% in 90 minutes.

Embodiment 2

[0033]0.026 g ferrous chloride tetrahydrate, 0.108 g ferric chloride hexahydrate and 9.8 mg BN were ultrasonically dispersed in 80 mL deionized water, heated to 90 °C in an oil bath, added 4 mL ammonia solution, and continued to react for 20 min. After washing with deionized water and ethanol, it is recovered by a magnet, and then dried to obtain magnetic Fe 2 o 3 / BN composites.

[0034] 10 mg of prepared magnetic Fe 2 o 3 The / BN composite material was put into a photochemical reaction apparatus for photocatalytic degradation test, and the total removal rate of tetracycline by the composite material reached 54% in 90 minutes.

Embodiment 3

[0036] 0.026 g of ferrous chloride tetrahydrate, 0.108 g of ferric chloride hexahydrate and 14 mg of BN were ultrasonically dispersed in 80 mL of deionized water, heated to 80 °C in an oil bath, 4 mL of ammonia solution was added, and the reaction was continued for half an hour, the product After washing with deionized water and ethanol, it is recovered by a magnet, and then dried to obtain magnetic Fe 2 o 3 / BN composites.

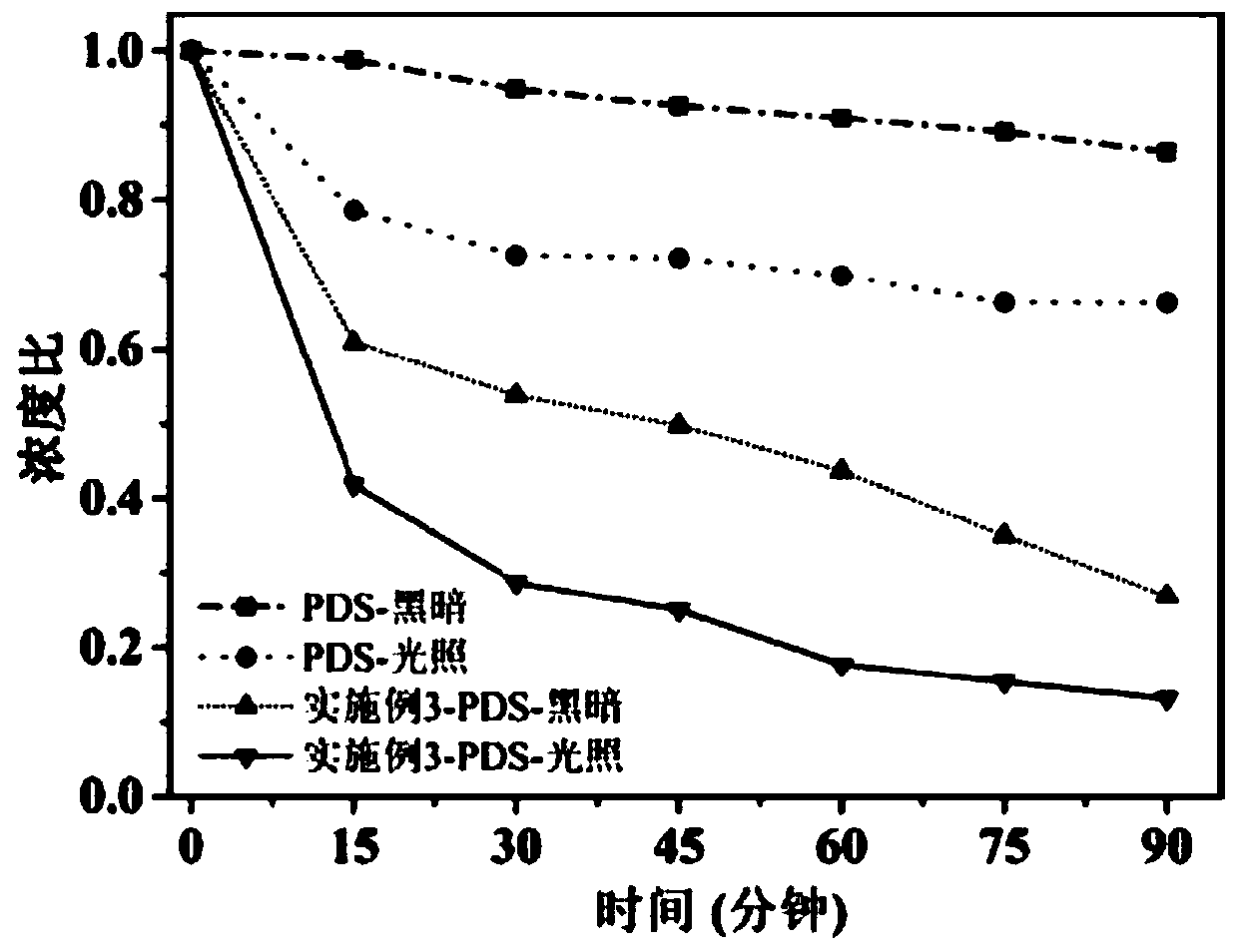

[0037] Take 10 mg of the prepared magnetic Fe 2 o 3 The / BN composite material was put into a photochemical reaction apparatus for photocatalytic degradation test, and it was measured that the total removal rate of tetracycline by the composite material reached 70% in 90 minutes.

[0038] Take 10 mg of the prepared magnetic Fe 2 o 3 / BN composites were placed in a photochemical reaction apparatus under dark conditions, and 50 mg PDS was added. It was measured that the removal rate of tetracycline reached 74% in 90 minutes under this condition.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com