Electric liquid beam machining method for super-hydrophobic square column array with liquid drop cake-shaped bouncing

A technology of super-hydrophobic square pillars and processing methods, which is applied in the direction of electric processing equipment, electrochemical processing equipment, metal processing equipment, etc., and can solve problems such as poor discharge of electro-etching products, serious loss of tool electrodes, and affecting processing quality. Achieve the effects of reduced liquid-solid contact time, low price, and low aspect ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

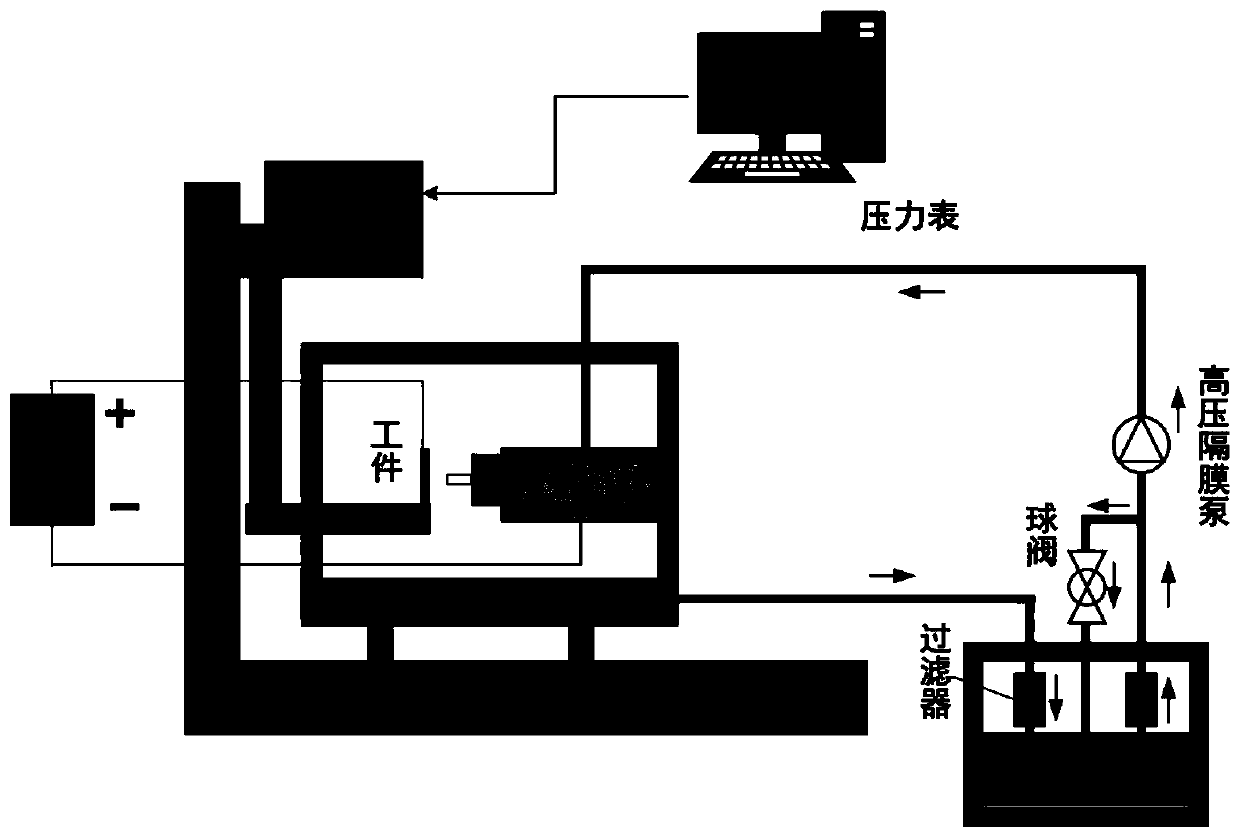

[0020] The method of electrohydraulic beam processing is used to obtain the superhydrophobic square column array that can realize the droplet cake bounce. The schematic diagram of the processing device is as follows figure 1 As shown, the specific method is as follows:

[0021] (1) Pretreatment: use 800# and 1500# sandpaper to polish the 304 stainless steel plate of 65mm×30mm×2mm and ultrasonically clean it with deionized water to remove the surface oxide layer and oil stain, and then dry it for later use;

[0022] (2) Electrohydraulic beam processing: Based on the built electrohydraulic beam processing device, the stainless steel plate and the plexiglass nozzle bonded with a 180 μm quartz capillary are arranged vertically, and the stainless steel plate fixed on the anode fixture is connected to the positive electrode through a lead screw to adjust the organic The machining gap between the end of the glass nozzle and the workpiece is 0.8mm, the high-voltage DC power supply is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com