Circular treatment method suitable for landscaping organic solid waste

A technology for organic solids and cyclic treatment, applied in application, fertilizer mixture, nitrogen fertilizer, etc., can solve the problems of low product quality, high organic carbon content, long fermentation cycle, etc., to reduce the impact of odor gas on the environment and ensure the safety of resources Utilization and zero emissions, to achieve the effect of product diversification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A recycling method suitable for landscaping organic solid wastes, comprising the following steps:

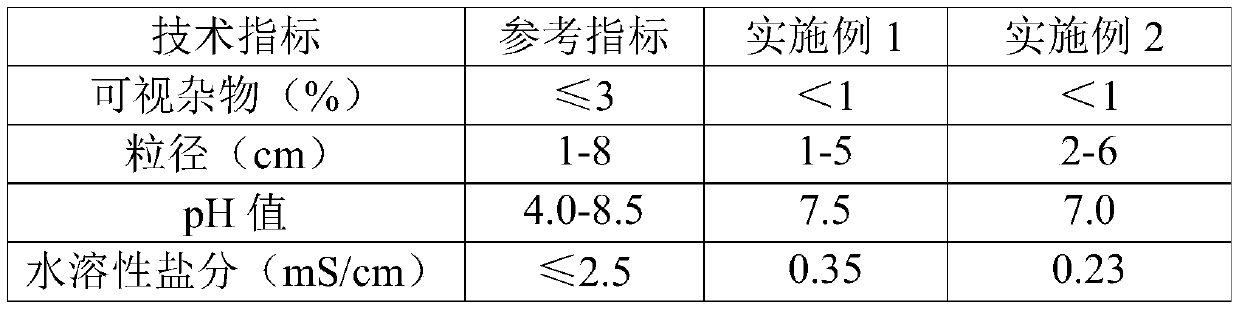

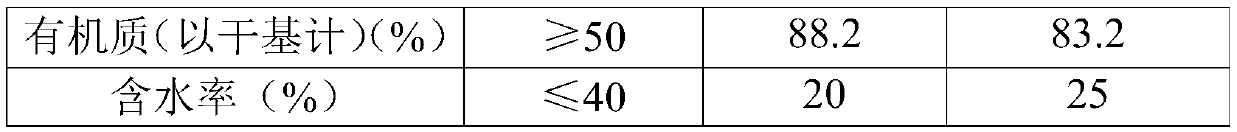

[0027] (1) Collect landscaping waste, including 2000kg of thick branches, 1500kg of branch and leaf trimmings, 500kg of lawn trimmings, and 200kg of plant residues, and grab the landscaping waste with a wooden clamp and enter the crushing equipment. The equipment adopts the crawler produced by the American MORBARK company The horizontal crusher adopts a unique pressure roller hammer grinding process, so that the thick branches are evenly hammered to form a wire-like medium-sized waste, and the remaining branches and leaves, lawn trimmings, and plant residual flowers are hammered and crushed , to form small-sized waste with uniform texture; the crushed mixed product is transported by the loader, and enters the mobile roller screen PRONAR with circular apertures of 1cm and 3cm respectively, and the small-sized waste and the medium-sized waste After sieving, the length of th...

Embodiment 2

[0035] A recycling method suitable for landscaping organic solid wastes, comprising the following steps:

[0036] (1) Collect landscaping waste, including 1500kg of thick branches, 1000kg of branch and leaf trimmings, 800kg of lawn trimmings, 150kg of plant residual flowers, and 50kg of seeds. The green waste is grabbed by a wooden clamp and entered into the hammer mill crushing equipment produced by MORBARK in the United States. Using unique pressure roller hammer grinding process, the particle size can be basically controlled within 10cm after a crushing through a customized screen. The pressure roller welded with wear-resistant and pressure-resistant material teeth and horizontal knives can be lifted and rotated freely through hydraulic power, thick branches After being evenly hammered and milled, it will form a wire-like wood fiber, and the remaining branch and leaf trimmings, lawn trimmings, and plant residual flowers will be hammered and pulverized to form small-sized was...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com