Polyaniline@silver nanowire/polyimide porous gradient composite film, and preparation method and application thereof

A technology of silver nanowires and polyimide, applied in the direction of instruments, analytical materials, measuring devices, etc., can solve the problems of hindering the contact between sensitive materials and gases, achieve good flexibility, increase adsorption active sites, and increase specific surface area Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

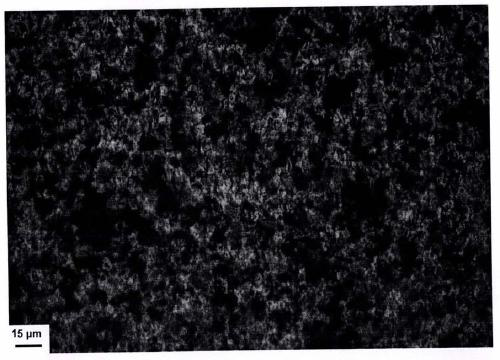

Image

Examples

Embodiment 1

[0028] The preparation method of the polyaniline@silver nanowire / polyimide porous gradient composite film in this embodiment is as follows:

[0029] (1) Preparation of the blend: 0.1g sodium chloride and 0.05g silver nanowires are added to the polyamic acid / dimethylformamide solution, and the stirring is continued to disperse evenly to form a blend; wherein, the chlorinated The mass ratio of sodium, polyamic acid and silver nanowires is 0.1:1:0.25; (2) Spin coating for the first time: Spin coating the above blend on a glass substrate to form a film, wherein the rotating speed is 700rmp / s, The time is 70s; (3) Spin coating for the second time: the polyamic acid / dimethylformamide solution that is not doped with sodium chloride and silver nanowires is spin-coated on the above-mentioned film, wherein, the rotating speed is 700rmp / s, Time 50s; (4) Curing: followed by heating and curing, in which, maintain at 100°C for 10 minutes, then maintain at 150°C for 20 minutes, then maintain...

Embodiment 2

[0031] The preparation method of the polyaniline@silver nanowire / polyimide porous gradient composite film in this embodiment is as follows:

[0032] (1) Preparation of the blend: Add 1g of sodium chloride and 0.2g of silver nanowires into the polyamic acid / dimethylformamide solution, and keep stirring to disperse evenly to form a blend; wherein, sodium chloride , the mass ratio of polyamic acid and silver nanowire is 0.7: 1: 0.65; (2) Spin coating for the first time: above-mentioned blend is spin-coated film-forming on glass substrate, and wherein, rotating speed is 700rmp / s, time (3) Spin coating for the second time: the polyamic acid / dimethylformamide solution that is not doped with sodium chloride and silver nanowires is spin-coated on the above-mentioned film, wherein, the rotating speed is 700rmp / s, and the time 50s; (4) Curing: followed by temperature rise curing, in which, maintain at 100°C for 10 minutes, then maintain at 150°C for 20 minutes, then maintain at 180°C fo...

Embodiment 3

[0034] The preparation method of the polyaniline@silver nanowire / polyimide porous gradient composite film in this embodiment is as follows:

[0035] (1) Preparation of the blend: 0.5g sodium chloride and 0.1g silver nanowires are added to the polyamic acid / dimethylformamide solution, and the stirring is continued to disperse evenly to form a blend; wherein, the chlorinated The mass ratio of sodium, silver nanowires and polyamic acid is 1.1:1:0.8; (2) Spin coating for the first time: spin-coat the above-mentioned blend on a glass substrate to form a film, wherein the rotating speed is 700rmp / s, The time is 70s; (3) Spin coating for the second time: the polyamic acid / dimethylformamide solution that is not doped with sodium chloride and silver nanowires is spin-coated on the above-mentioned film, wherein, the rotating speed is 700rmp / s, Time 50s; (4) Curing: followed by heating and curing, in which, maintain at 100°C for 10 minutes, then maintain at 150°C for 20 minutes, then mai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com