Composite material containing FeS2 and reduced iron as well as preparation method and application of the composite material

A technology of composite materials and reduced iron, which is applied in the field of soil pollution remediation, can solve problems such as difficult engineering application, complicated preparation methods, and low remediation efficiency, and achieve the effects of low cost, simple preparation method, and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

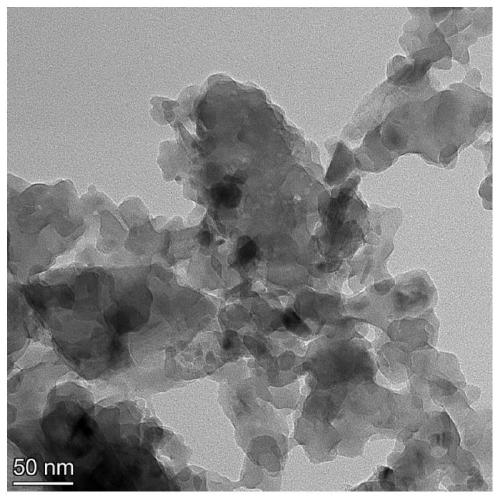

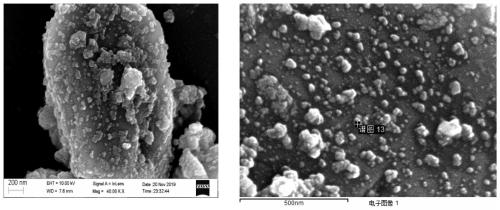

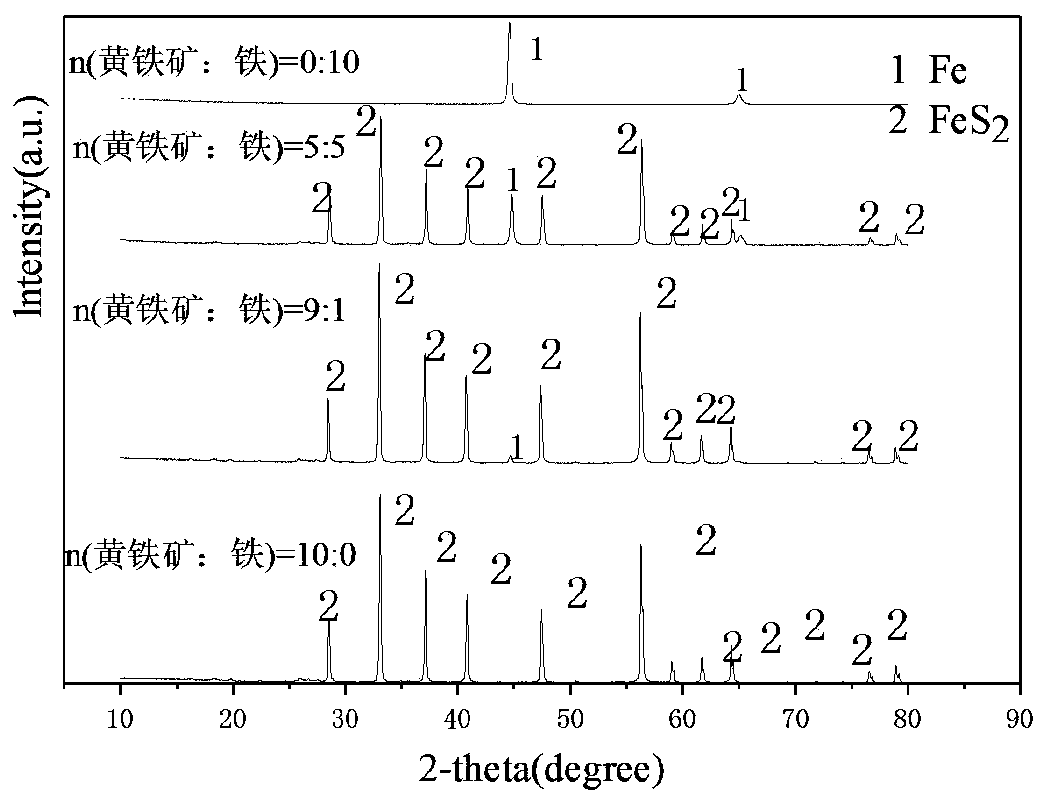

[0060] Select FeS 2 The pyrite whose mass fraction is greater than 95% is dried, vibrating and sieved through 20 mesh to obtain pyrite particles; fully mix the pyrite and iron powder (over 20 mesh) molar ratio of 9:1, add the total mass of The citric acid with a fraction of 1% is put into a hard stainless steel ball mill tank, and balls are added according to a ball-to-material ratio of 15:1. The ball mill is an omnidirectional planetary ball mill, and the ball mill speed is set to 400 rpm. After 4 hours of mechanical ball milling, After sieving through 100 meshes, the required hexavalent chromium-contaminated soil remediation material is obtained.

Embodiment 2

[0062] Select the tailings of an iron ore, crush it, take a high-purity pyrite sample, wash and air-dry it, and then grind it through a 20-mesh sieve (the contents of Fe and S are 47.33% and 51.68%, respectively, according to chemical composition analysis), and obtain Pyrite particles; fully mix according to the molar ratio of pyrite and iron powder (over 20 mesh) 9:1, add citric acid with a total material mass fraction of 1%, put it into a hard stainless steel ball mill tank, and press the ball-to-material ratio of 15 : 1 Add grinding balls, the ball mill is an omnidirectional planetary ball mill, the setting ball milling speed is 400 rpm, after mechanical ball milling for 4 hours, sieve through 100 meshes to obtain the required hexavalent chromium-contaminated soil remediation material.

Embodiment 3

[0064] Weighing 20g of contaminated soil with a hexavalent chromium content of 448.1mg / kg is placed in a polytetrafluoroethylene beaker, adding 1g of the economical and easy-to-preparation hexavalent chromium-contaminated soil restoration material described in Example 1, according to the soil-water mass ratio 2:1 Add pure water and stir until uniform. The samples were taken at the reaction time of 1, 2, 5, 7, 14, and 30 days, and then dried at 60°C for 6 hours. The content of hexavalent chromium in the soil was extracted by alkaline digestion (EPA METHOD 3060B). Phenylcarbazide spectrophotometric determination of hexavalent chromium concentration. Experimental results such as Figure 7 As shown, after 30 days of treatment, the concentration of total hexavalent chromium in the soil was 2.5mg / kg, and the removal rate of total hexavalent chromium in the soil reached 99.44%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com