Method for preparing light-colored conductive TiO2 whisker/superpolymer composite antistatic fiber

An antistatic fiber and high polymer technology, applied in the manufacture of conductive/antistatic filaments, fiber chemical characteristics, single-component synthetic polymer rayon, etc., can solve problems such as the dispersion and persistence of conductive nanoparticles, and achieve Good corona discharge effect, excellent antistatic performance, and high whiteness value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

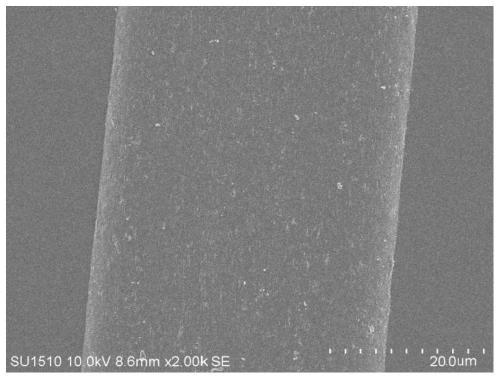

[0028] Example 1: Light-colored conductive TiO based on corona discharge effect 2 The preparation method of whisker / polymer composite antistatic fiber, concrete steps are as follows:

[0029] (1) Dissolve tin tetrachloride and antimony trichloride in 2mol / L hydrochloric acid solution at a molar ratio of 1:10 and stir until the solution is clear, and add 8mol / L H 2 o 2 solution until H 2 o 2 : Hydrochloric acid molar ratio is 1:1, obtain solution A after fully mixing, set aside. Configure a certain 2M sodium hydroxide solution for standby;

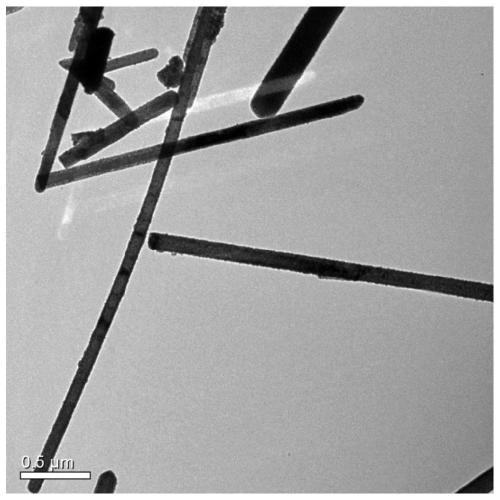

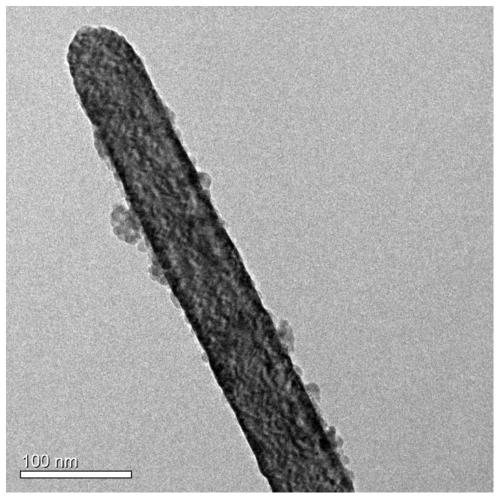

[0030] (2) TiO with an average diameter of 150 nm and an average length of 3 μm was prepared using a chemical method 2 Whiskers, and surface treatment with 5M sodium hydroxide solution. The treatment time is 8h, and the temperature is 80°C. to TiO 2 Whiskers were suction filtered at 0.05MPa; then the TiO 2 Wash the whiskers until neutral, dry at room temperature for 8 hours, and set aside.

[0031] (3) Light-colored conductive TiO...

Embodiment 2

[0039] Example 2: Light-colored conductive TiO based on corona discharge effect 2 The preparation method of whisker / polymer composite antistatic fiber, concrete steps are as follows:

[0040] (1) Dissolve tin tetrachloride and antimony trichloride in 2.5mol / L hydrochloric acid solution at a molar ratio of 1:10 and stir until the solution is clear, and add 12mol / L H 2 o 2 solution until H 2 o 2 : Hydrochloric acid molar ratio is 1:1, obtain solution A after fully mixing, set aside. Configure a certain 2M sodium hydroxide solution for standby;

[0041] (2) TiO with an average diameter of 150 nm and an average length of 3 μm was prepared using a chemical method 2 Whiskers were treated with 5 M NaOH solution. The treatment time was 8 h and the temperature was 80 °C. to TiO 2 Whiskers were suction filtered at 0.1MPa; then the TiO 2 Wash the whiskers until neutral, dry at room temperature for 8 hours, and set aside.

[0042] (3) Light-colored conductive TiO 2 Whisker prep...

Embodiment 3

[0050] Example 3: Light-colored conductive TiO based on corona discharge effect 2 The preparation method of whisker / polymer composite antistatic fiber, concrete steps are as follows:

[0051] (1) Dissolve tin tetrachloride and antimony trichloride in 2.2mol / L hydrochloric acid solution at a molar ratio of 1:10 and stir until the solution is clear, and add 10mol / L H 2 o 2 Solution, get solution A after thorough mixing, set aside. Configure a certain 2 M sodium hydroxide solution for standby;

[0052] (2) Using a chemical method to prepare TiO with an average diameter of 150 nm and an average length of 3 μm 2 Whiskers were treated with 5 M NaOH solution. The treatment time is 8h, and the temperature is 80°C. to TiO 2 Whiskers were suction filtered at 0.08MPa; followed by distilled water with a weak acid of 0.02mol / L 2 Wash the whiskers until neutral, dry at room temperature for 10 h, and set aside.

[0053] (3) Light-colored conductive TiO 2 Whisker preparation:

[005...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com