Dyeing method of bamboo fiber fabric based on mahonia bealei plant dye

A bamboo fiber fabric, a technology with ten merits, applied in the field of fabric dyeing, can solve the problems of harmful heavy metals in dyes, large water consumption, high processing difficulty, and achieve the effects of easy transportation and use, improved production efficiency, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

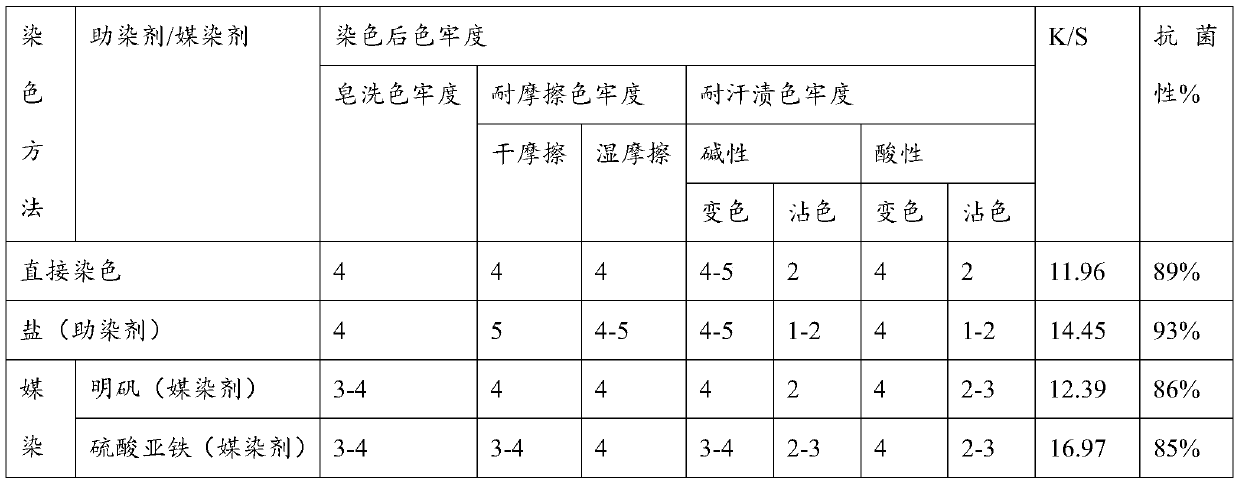

Image

Examples

Embodiment 1

[0054] 1. Fabric pretreatment:

[0055] ①Desizing: α-starch biological enzyme is used in the desizing process, the temperature is controlled above 90℃, the pH range is controlled at 5.0-8.0, the time is 45min, the liquor ratio is 1:35, and the mass fraction is α-starch with a mass fraction of 1.5g / L Bio-enzyme for steam desizing of bamboo fiber fabrics.

[0056] ② Scouring: The scouring process uses scouring enzyme LS, and the scouring optimization process is: scouring enzyme LS 2g / L, surfactant 0.8g / L, liquor ratio 1:15, pH value=9, temperature 60℃ , time 30min.

[0057] ③Bleaching: The bleaching process uses hydrogen peroxide and hydrogen peroxide biological enzymes.

[0058] The first step, with Na 2 CO 3 Concentration 3g / L, Na 2 Si0 3 The concentration of 5g / L and NaOH concentration of 1.2g / L were used as hydrogen peroxide buffer solution. Under the condition of liquor ratio of 1:30, the concentration of hydrogen peroxide was 9g / L, the bleaching temperature was 95°C,...

Embodiment 2

[0065] 1. Fabric pretreatment:

[0066] ①Desizing: α-starch biological enzyme is used in the desizing process, the temperature is controlled above 90°C, the pH range is controlled at 5.0-8.0, the time is 35min, the liquor ratio is 1:40, and the mass fraction is α-starch with a mass fraction of 1.3g / L Bio-enzyme for steam desizing of bamboo fiber fabrics.

[0067] ② Scouring: Scouring enzyme LS is used in the scouring process. The specific process is: scouring enzyme LS 2g / L, surfactant 0.8g / L, liquor ratio 1:13, pH value=10, temperature 65℃, time 28min.

[0068] ③Bleaching: The bleaching process uses hydrogen peroxide and hydrogen peroxide biological enzymes.

[0069] The first step, with Na 2 CO 3 Concentration 2.8g / L, Na 2 Si0 3 The concentration of 4.8g / L and the concentration of NaOH 1g / L were used as hydrogen peroxide buffer solution. Under the condition of liquor ratio of 1:28, the concentration of hydrogen peroxide was 7g / L, the bleaching temperature was 90℃, and ...

Embodiment 3

[0075] 1. Fabric pretreatment:

[0076] ①Desizing: α-starch biological enzyme is used in the desizing process, the temperature is controlled above 90°C, the pH range is controlled at 5.0-8.0, the time is 35min, the liquor ratio is 1:40, and the mass fraction is α-starch with a mass fraction of 1.3g / L Bio-enzyme for steam desizing of bamboo fiber fabrics.

[0077] ② Scouring: The scouring process uses scouring enzyme LS, and the scouring optimization process is: scouring enzyme LS 2.2g / L, surfactant 1.9g / L, liquor ratio 1:16, pH value = 8, temperature 55 ℃, time 32min.

[0078] ③Bleaching: The bleaching process uses hydrogen peroxide and hydrogen peroxide biological enzymes.

[0079] The first step, with Na 2 CO 3 Concentration 3.2g / L, Na 2 Si0 3 The concentration of 4.8g / L and the concentration of NaOH of 1g / L were used as hydrogen peroxide buffer solution. Under the condition of liquor ratio of 1:28, the concentration of hydrogen peroxide was 10g / L, the bleaching temper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com