Silver sulfide-based inorganic thermoelectric material and preparation method and application thereof

A technology of thermoelectric materials and silver sulfide, which is applied in the direction of thermoelectric device junction lead-out materials, thermoelectric device manufacturing/processing, thermoelectric devices that only use Peltier or Seebeck effect, etc., can solve the problem of low carrier concentration of silver sulfide, Not suitable for problems such as thermoelectric materials, to achieve the effects of easy mass production, good flexibility, and huge application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

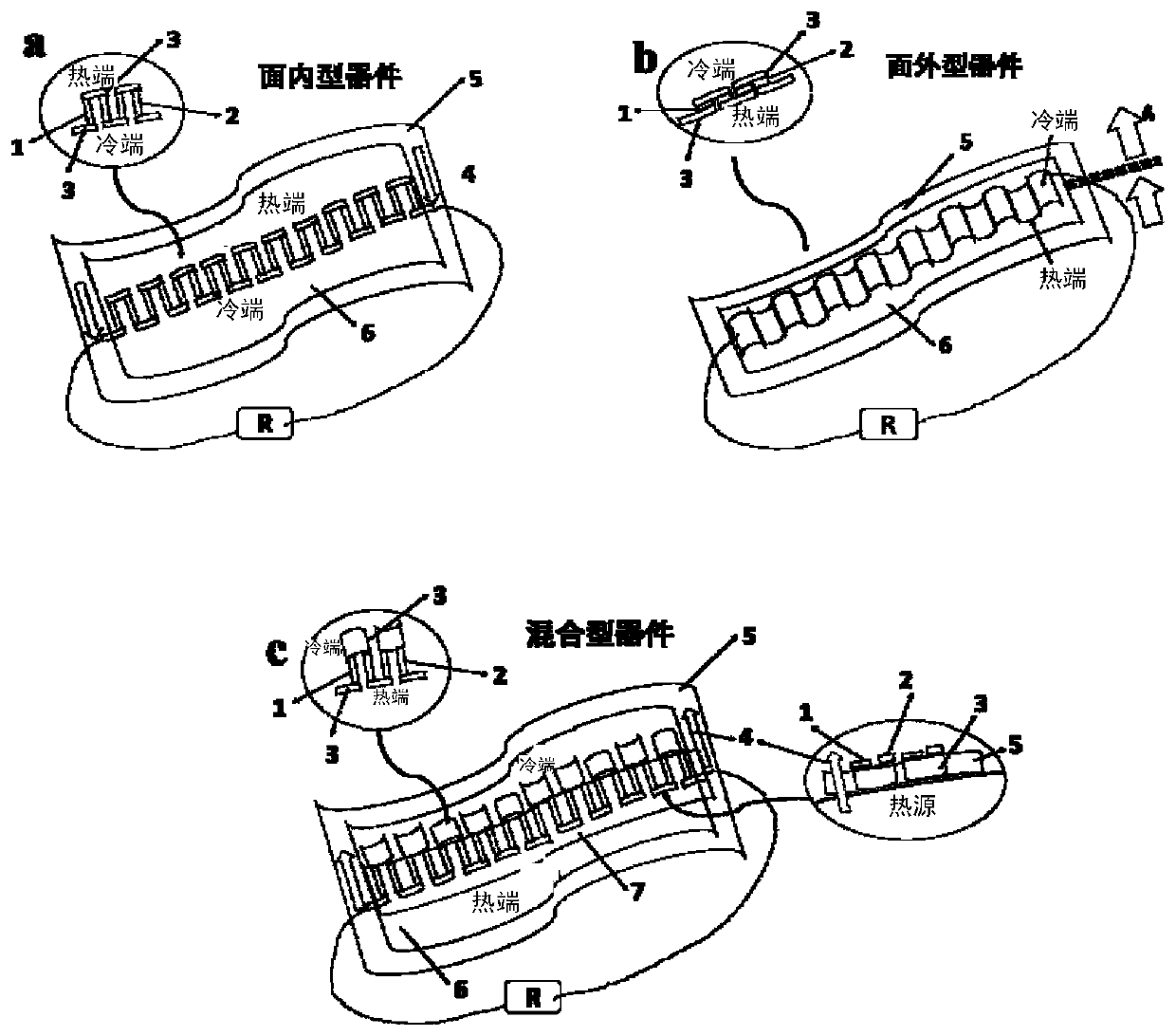

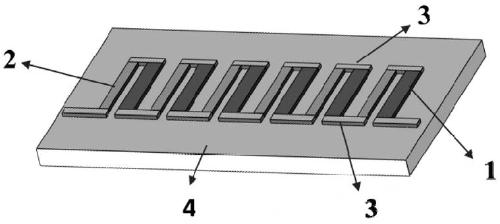

[0038] In one embodiment of the present invention, the preparation method of a flexible thermoelectric device based on silver sulfide-based inorganic thermoelectric material includes: cutting out a thermoelectric arm of a specific size from a dense bulk silver sulfide-based inorganic thermoelectric material. The electrodes are connected with silver sulfide-based thermoelectric arms to form a thermoelectric pair in series. A flexible thermoelectric device is obtained by adhering multiple groups of thermoelectric pairs composed of silver sulfide-based inorganic thermoelectric materials on a flexible substrate.

[0039] The silver sulfide-based inorganic thermoelectric material is prepared as a thermoelectric arm in a silver sulfide-based inorganic flexible thermoelectric device, including: casting an ingot of the silver sulfide-based inorganic thermoelectric material or a dense block of the sintered silver sulfide-based thermoelectric material, using a diamond cutter , Internal ...

Embodiment 1

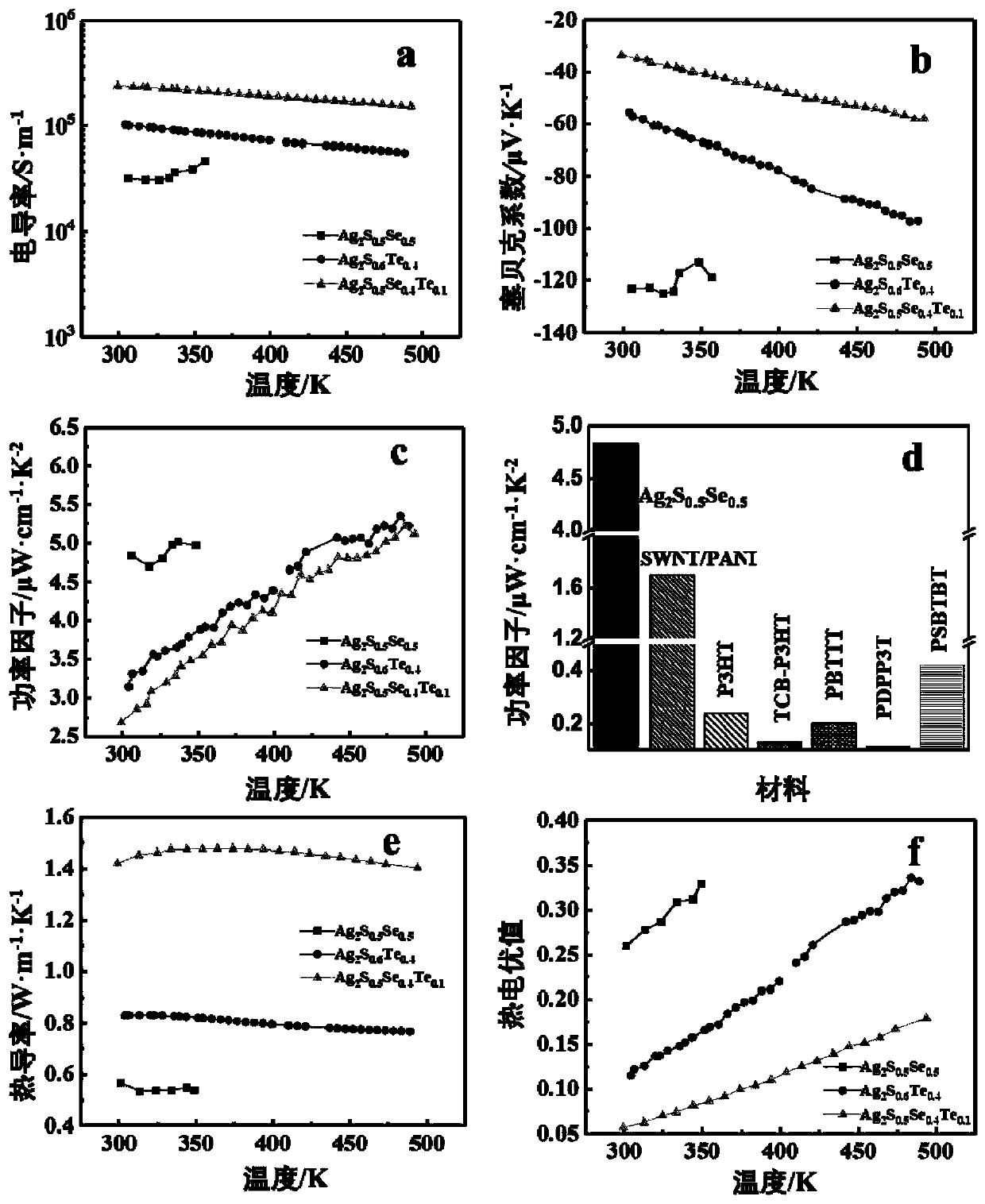

[0049] This Example 1 is an in-plane type device. Preparation of N-type Ag 2 S 0.5 Se 0.5 Materials: Weigh high-purity Ag, S, and Se elements according to the stoichiometric ratio of 4:1:1. It is added into a Φ10 thick quartz tube for vacuum packaging; the packaged quartz tube is heated to 1000°C at a heating rate of 40 hours and kept for 12 hours, then cooled to 100°C within 25 hours, and then the quartz tube is annealed at 450°C for 5 sky. The annealed Ag 2 S 0.5 Se 0.5 The ingot was smashed into powder with a stainless steel pestle under a liquid nitrogen environment. The powder was then sintered at 190 °C for 0.5 h using spark plasma sintering to finally obtain dense N-type Ag 2 S 0.5 Se 0.5 blocks. In the three-point bending test, the dense N-type Ag 2 S 0.5 Se 0.5 The bulk can withstand 12% mechanical strain without rupture; in compression tests, dense N-type Ag 2 S 0.5 Se 0.5 The blocks can withstand up to 55% mechanical strain without breaking. Its th...

Embodiment 2

[0051] This Example 2 is an out-of-plane device. Preparation of N-type Ag 2 S 0.6 Te 0.4 Materials: Weigh high-purity Ag, S, and Te elements according to the stoichiometric ratio of 10:3:2. It is added into a Φ10 thick quartz tube for vacuum packaging; the packaged quartz tube is heated to 1000°C at a heating rate of 40 hours and kept for 12 hours, then cooled to 100°C within 25 hours, and then the quartz tube is annealed at 450°C for 5 sky. The annealed Ag 2 S 0.6 Te 0.4 The ingot was smashed into powder with a stainless steel pestle under a liquid nitrogen environment. The powder was then sintered at 320 °C for 0.5 h using spark plasma sintering to finally obtain dense N-type Ag 2 S 0.6 Te 0.4 blocks. Its thermoelectric properties are as figure 2 As shown, at 300K, its power factor is 3.1μW·cm -1 ·K -2 , much higher than conventional organic thermoelectric materials. In the three-point bending test, a dense N-type Ag 2 S 0.6 Te 0.4 The bulk can withstand 8...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Power factor | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com