Microbial fuel cell anode biochar composite material and preparation method thereof

A fuel cell and composite material technology, applied in battery electrodes, circuits, electrical components, etc., can solve problems such as low power density and current density, low power density and current density, and low power production, and achieve improved power production performance. Material cost, effect of reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

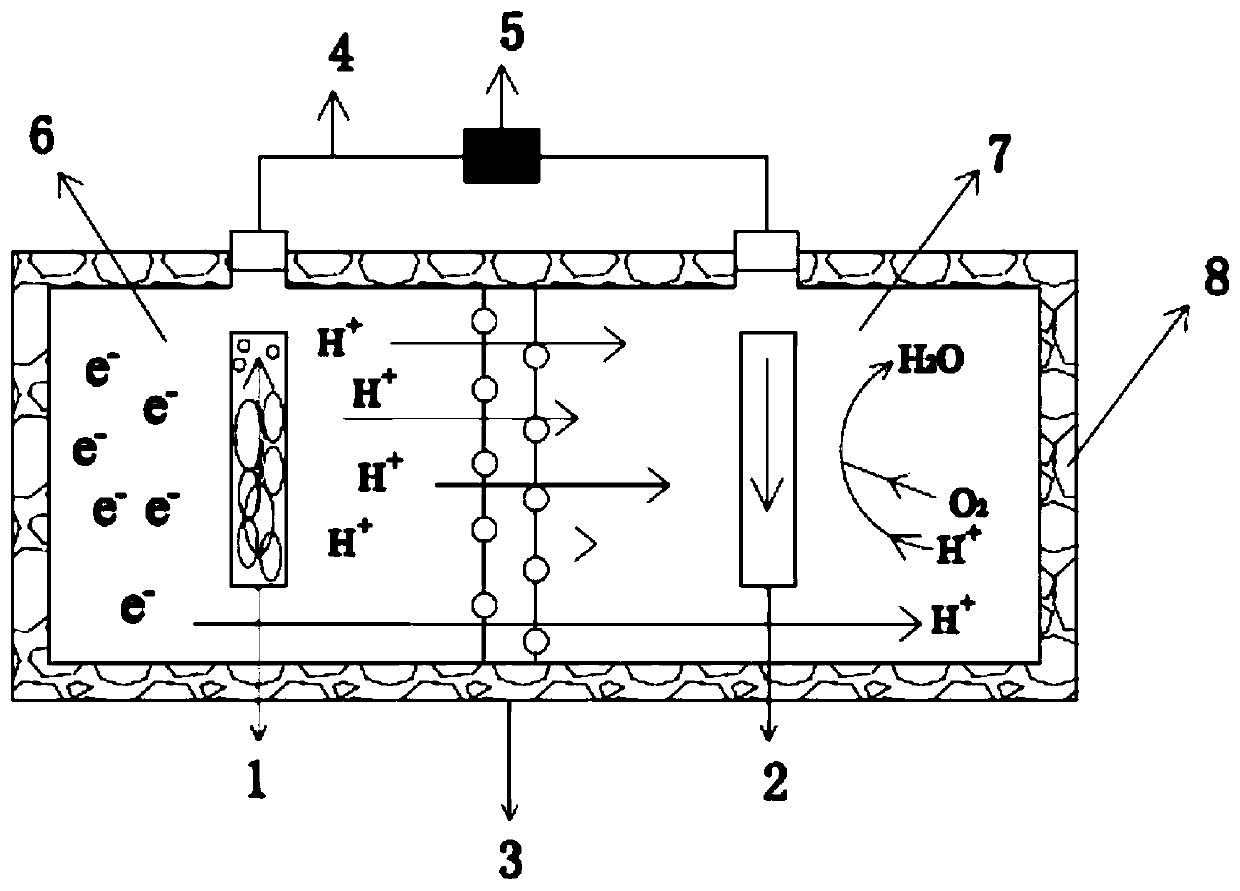

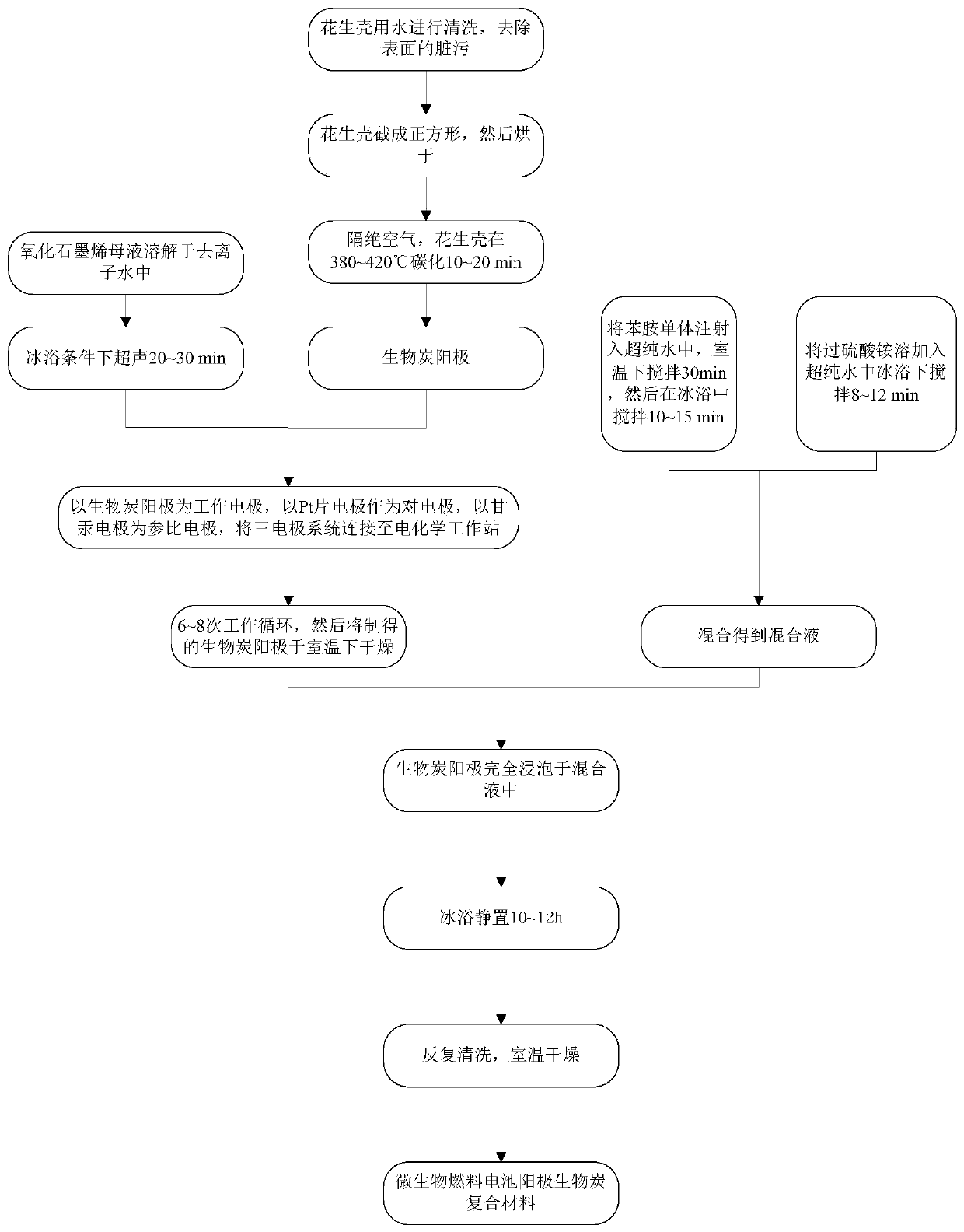

[0049] Such as figure 2 Shown: a preparation method of microbial fuel cell anode biochar composite material, comprising the following steps:

[0050] (1) Preparation of biochar anode:

[0051] (11) Wash the peanut shells with water to remove the dirt on the surface, then cut the peanut shells into squares, then dry them at 85°C for 1.5 hours, and dry them for later use;

[0052] (12), under the condition of isolating the air, the electric resistance furnace is heated to 400° C., and then the dried peanut shells obtained in step (11) are placed therein for carbonization for 15 minutes, and then cooled to room temperature with the furnace to obtain a biochar anode;

[0053] (2) Preparation of microbial fuel cell anode biochar composite material:

[0054] (21), dissolving the graphene oxide mother liquor in deionized water, and configuring it to a concentration of 0.075mg / ml -1 Graphene oxide aqueous solution, after ultrasonic 25min under ice bath condition, enter step (22) a...

specific Embodiment 2

[0065] A preparation method of microbial fuel cell anode biochar composite material, comprising the following steps:

[0066] (1) Preparation of biochar anode:

[0067] (11) Wash the peanut shells with water to remove the dirt on the surface, then cut the peanut shells into squares, then dry them at 80°C for 2 hours, and dry them for later use;

[0068] (12), the electric resistance furnace is heated to 380° C. under the condition of isolating the air, and then the dried peanut shells obtained in step (11) are placed therein for carbonization for 20 minutes, and then cooled to room temperature with the furnace to obtain a biochar anode;

[0069] (2) Preparation of microbial fuel cell anode biochar composite material:

[0070] (21) Dissolve the graphene oxide mother liquor in deionized water and configure it to a concentration of 0.05mg / ml -1 Graphene oxide aqueous solution, after ultrasonic 20min under ice bath condition, enter step (22) after finishing;

[0071] (22) Use a...

specific Embodiment 3

[0081] A preparation method of microbial fuel cell anode biochar composite material, comprising the following steps:

[0082] (1) Preparation of biochar anode:

[0083] (11) Wash the peanut shells with water to remove the dirt on the surface, then cut the peanut shells into squares, then dry them at 90°C for 1 hour, and dry them for later use;

[0084] (12), under the condition of air isolation, the electric resistance furnace is heated to 420° C., and then the dried peanut shells obtained in step (11) are placed therein for carbonization for 10 minutes, and then cooled to room temperature with the furnace to obtain a biochar anode;

[0085] (2) Preparation of microbial fuel cell anode biochar composite material:

[0086] (21), dissolving the graphene oxide mother liquor in deionized water, and configuring it to a concentration of 0.1mg / ml -1 Graphene oxide aqueous solution, after ultrasonic 30min under ice bath condition, enter step (22) after finishing;

[0087] (22) Use ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com