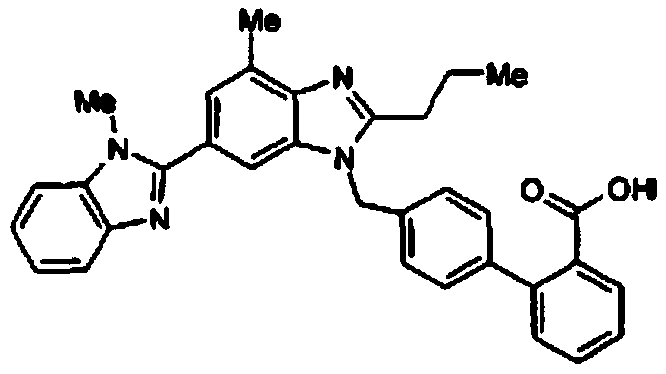

Telmisartan tablets and preparation method thereof

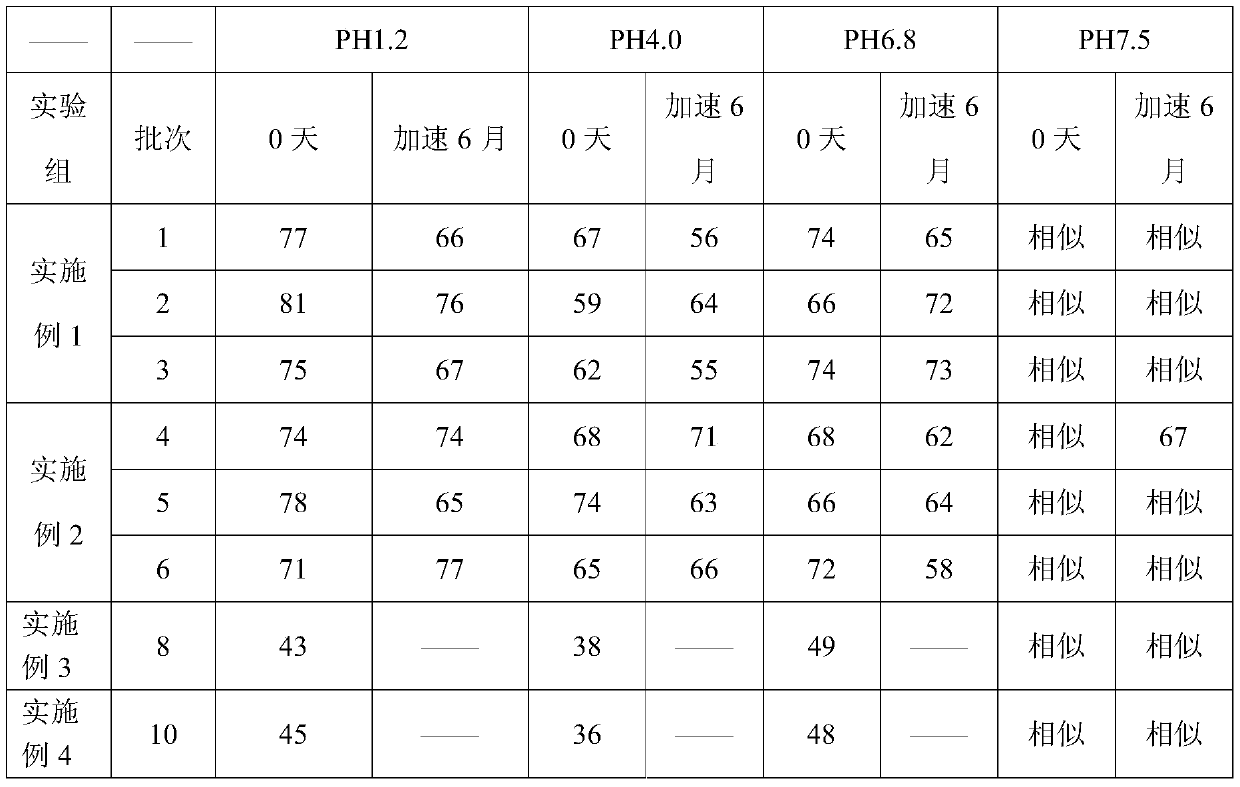

A technology of telmisartan and sodium salt, applied in the field of telmisartan tablets and preparation thereof, can solve the problems of large difference, long time consumption, manpower and material resources, etc., and achieves good product stability, simple process operation, and improved similarity. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] A kind of preparation method of telmisartan tablet comprises the steps:

[0055] 1. 40g telmisartan, 3.3g sodium hydroxide, and 12g meglumine were prepared into 90g ethanol aqueous solution (2:1);

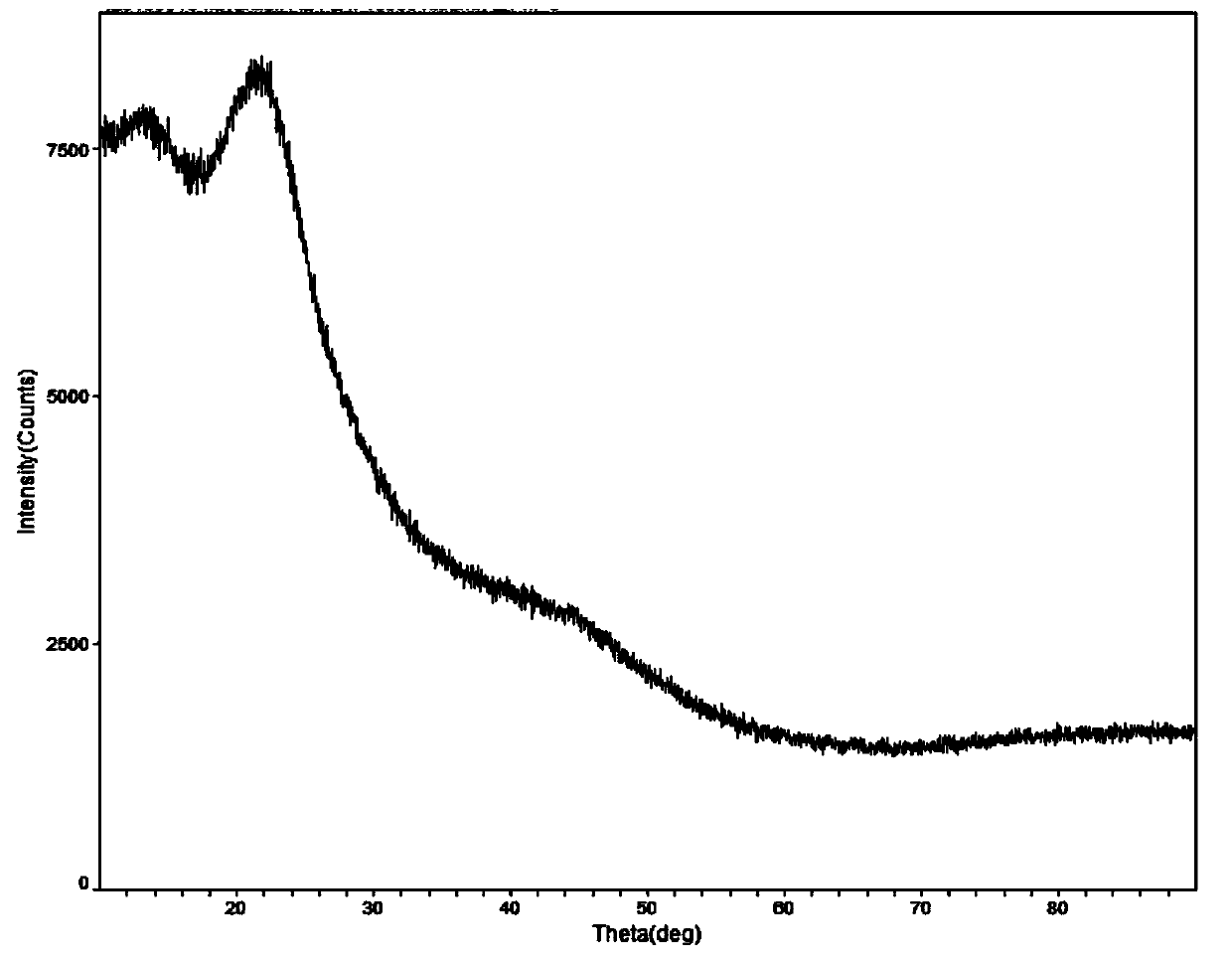

[0056] 2. The prepared solution was distilled under reduced pressure at 80°C, and the precipitated particles were dissolved in 90 g of ethanol, and then evaporated to dryness for recrystallization, finally obtaining an amorphous sodium salt particle;

[0057] 3. Add the prepared sodium salt granules, 160g sorbitol, and 20g povidone K30 into a wet mixing granulator, stir and shear for 20min, add 4.8g purified water to make a soft material, granulate, and fluidize the bed at 60°C For drying, the parameters of the fluidized bed are: the inlet air temperature is 50°C, the fan frequency is 30Hz, and the material temperature is controlled at about 40°C. The moisture content is controlled not to be higher than 3.5% to obtain dry granules; the dried granules are sized and passed th...

Embodiment 2

[0061] A kind of preparation method of telmisartan tablet comprises the steps:

[0062] 1. 80g telmisartan, 7.0g sodium hydroxide, and 30g meglumine were prepared into 180g ethanol aqueous solution (2:1);

[0063] 2. The prepared solution was distilled under reduced pressure at 90°C, and the precipitated particles were dissolved in 180 g of acetone, and then evaporated to dryness again for recrystallization, finally obtaining a crystal form of amorphous sodium salt particles.

[0064] 3. Add the prepared sodium salt granules, 300g sorbitol, and 40g povidone K30 into a wet mixing granulator, stir and shear for 20 minutes, add 14.4g purified water to make a soft material, granulate, and fluidize the bed at 60°C For drying, the parameters of the fluidized bed are: spraying speed 10r / min, air inlet temperature 50°C, fan frequency 30Hz, material temperature controlled at about 40°C. The moisture content is controlled not to be higher than 3.5% to obtain dry granules; the dried gra...

Embodiment 3

[0068] Preparation method I (control group 1) of prior art telmisartan tablet:

[0069] The sodium hydroxide 3.36g that weighed recipe quantity (in 1000 pieces) joins 150mL purified water, after stirring and dissolving, add meglumine 12g, after stirring and dissolving completely, add telmisartan raw material 40g, after stirring and dissolving completely, Finally, 12g of povidone was added, stirred and dissolved, and ultrasonically degassed to obtain a slurry. Weighed 122.24g of mannitol as a substrate and added it to a fluidized bed for granulation, plus 31.92g of mannitol, 12g of hydroxypropyl cellulose, and stearin Magnesium acid 1.68g, talcum powder 4.8g are mixed and compressed into tablets to obtain Telmisartan tablets. Among them, the parameters of the fluidized bed are: the spraying speed is 10r / min, the air inlet temperature is 50°C, the fan frequency is 30Hz, and the material temperature is controlled at about 40°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com