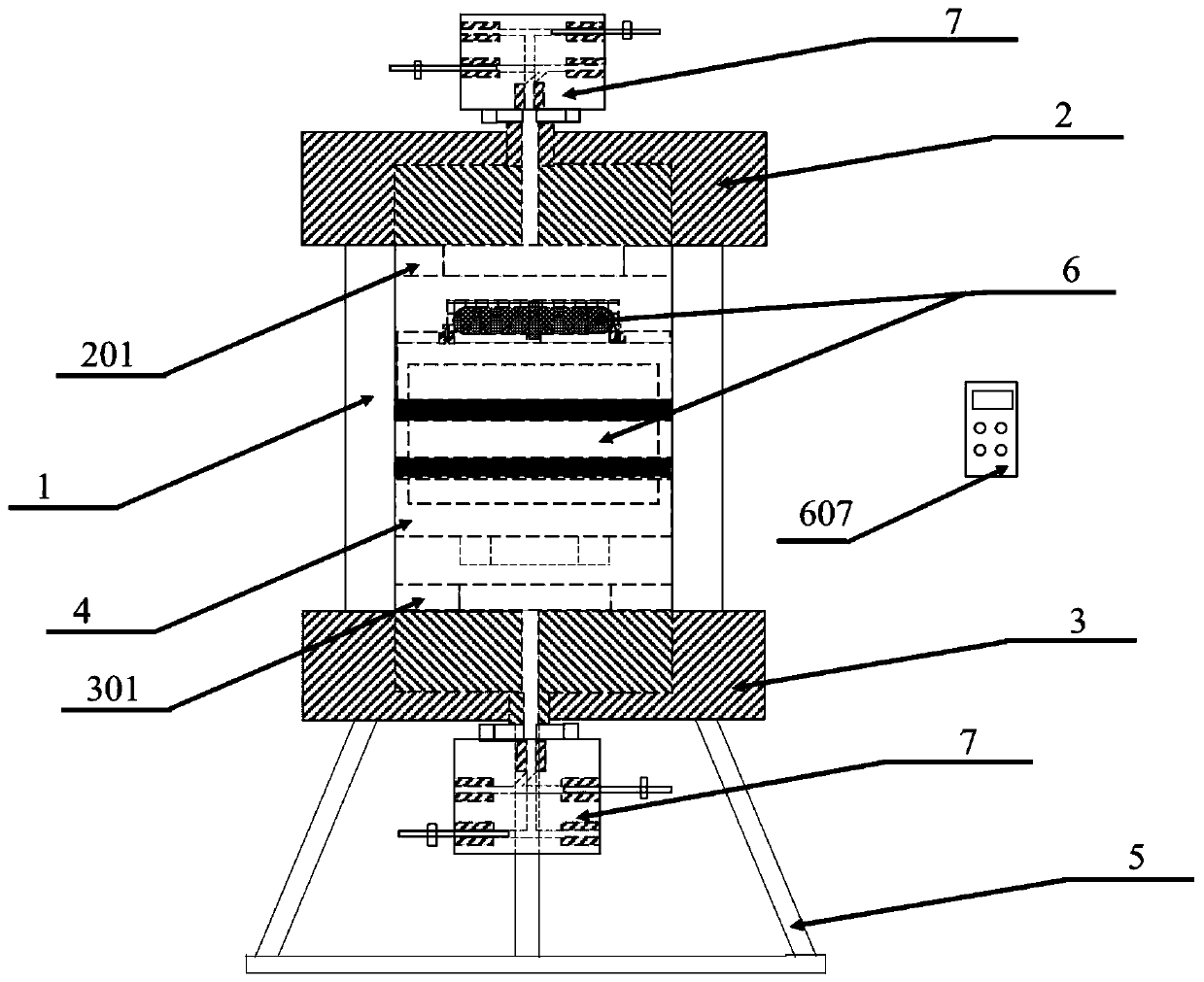

High-temperature-resistant and high-pressure-resistant stirring intermediate container device and porous medium displacement experiment system

A technology for intermediate containers and porous media, which is applied in mixer accessories, chemical instruments and methods, transportation and packaging, etc., and can solve problems affecting the pressure resistance of intermediate containers, poor pressure resistance of intermediate containers, and poor heat resistance of stirring motors, etc. , to achieve the effect of improving stirring stability, solving sealing and pressure bearing problems, and saving space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

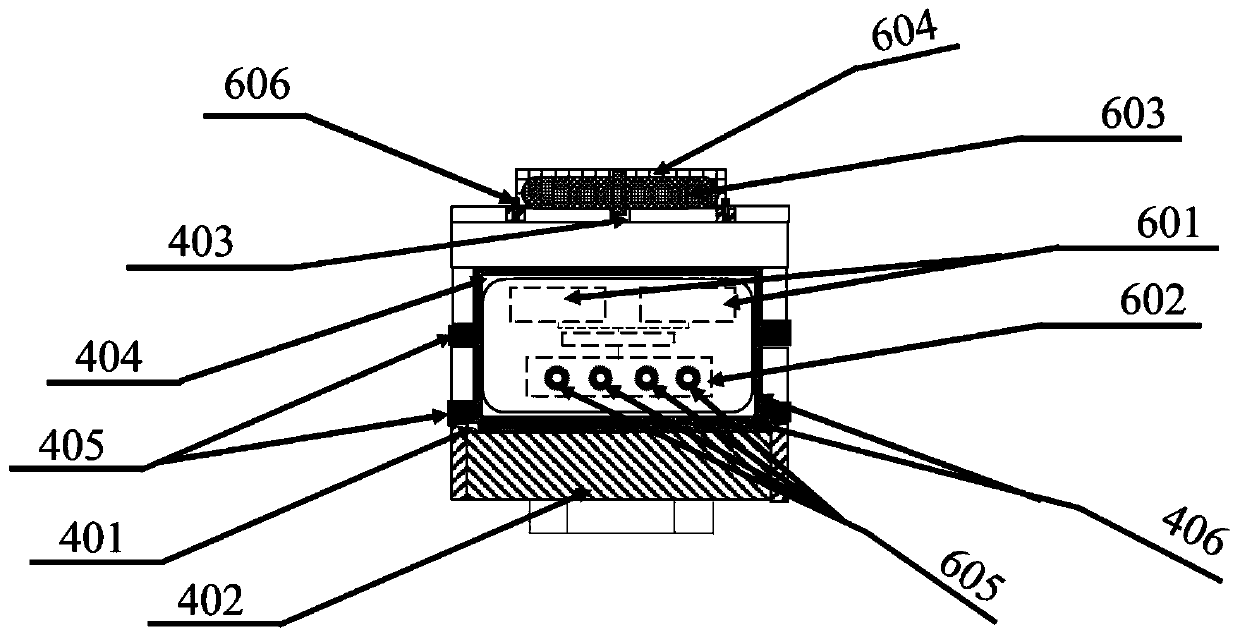

[0051] Such as Figure 6 As shown, before the experiment, in order to further determine the feasibility of the device, the stirring mechanism 6 was taken out separately, and the piston mechanism 4 was removed, and the magnetic rotor 603 was put into a transparent airtight container filled with water, and it was found that the container was filled with water. In the state, the magnetic rotor 603 can still rotate normally. Therefore, when the intermediate container is filled with the experimental fluid and sealed, the magnetic rotor 603 can also work normally, and the experimental stirring function can be achieved.

Embodiment 2

[0053] Such as Figure 7 As shown, in order to further confirm the feasibility of the device, the magnetic rotor 603 is placed in a stainless steel intermediate container with a wall thickness of 1 cm, placed on a magnetic stirrer, and the magnetic stirring can still be performed normally after the saturated water is pressurized to 10 MPa. Therefore, in the process of pressurized displacement, the pressure does not affect the work of the magnetic rotor 603, and the function of continuous mixing and stirring can be realized, and the process temperature is 100°C, and the experimental process is resistant to high temperature and high pressure. This embodiment is to verify the effect of magnetic stirring under pressure, and simulate the situation where the magnetic rotor 603 is stirred after being pressurized in the high-temperature and high-pressure stirrable intermediate container device 9 . Through this embodiment, it is verified that the experiment runs stably and the scheme i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com