Laundry condensation beads, processing device and processing method

A technology of laundry beads and processing equipment, which is applied to chemical instruments and methods, detergent materials, detergent compounding agents, etc., and can solve problems such as inability to separate laundry beads

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

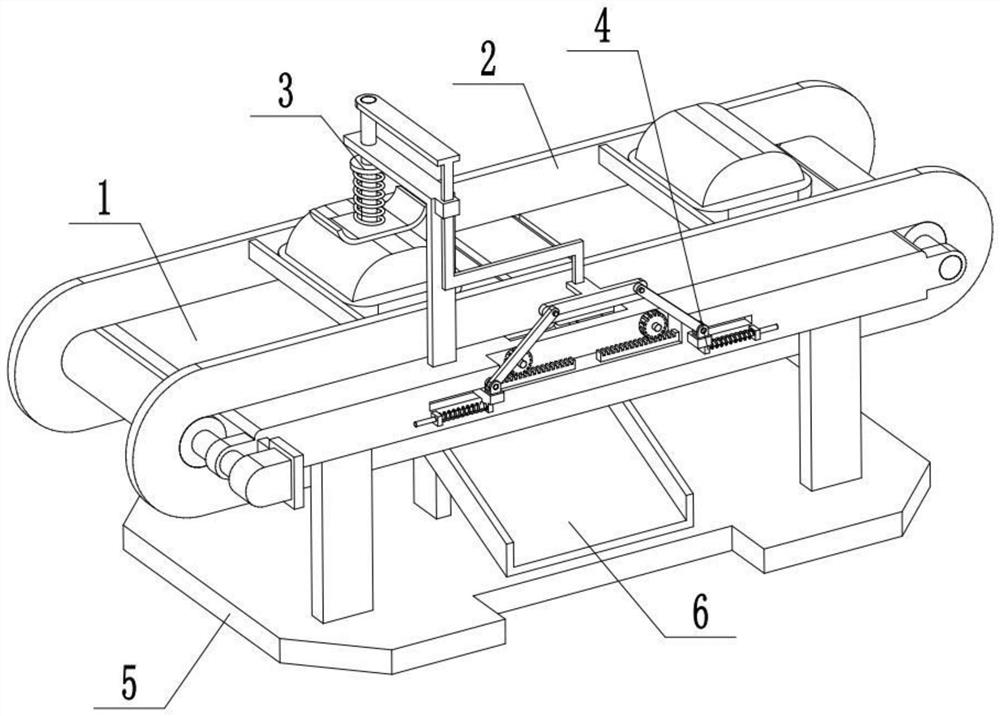

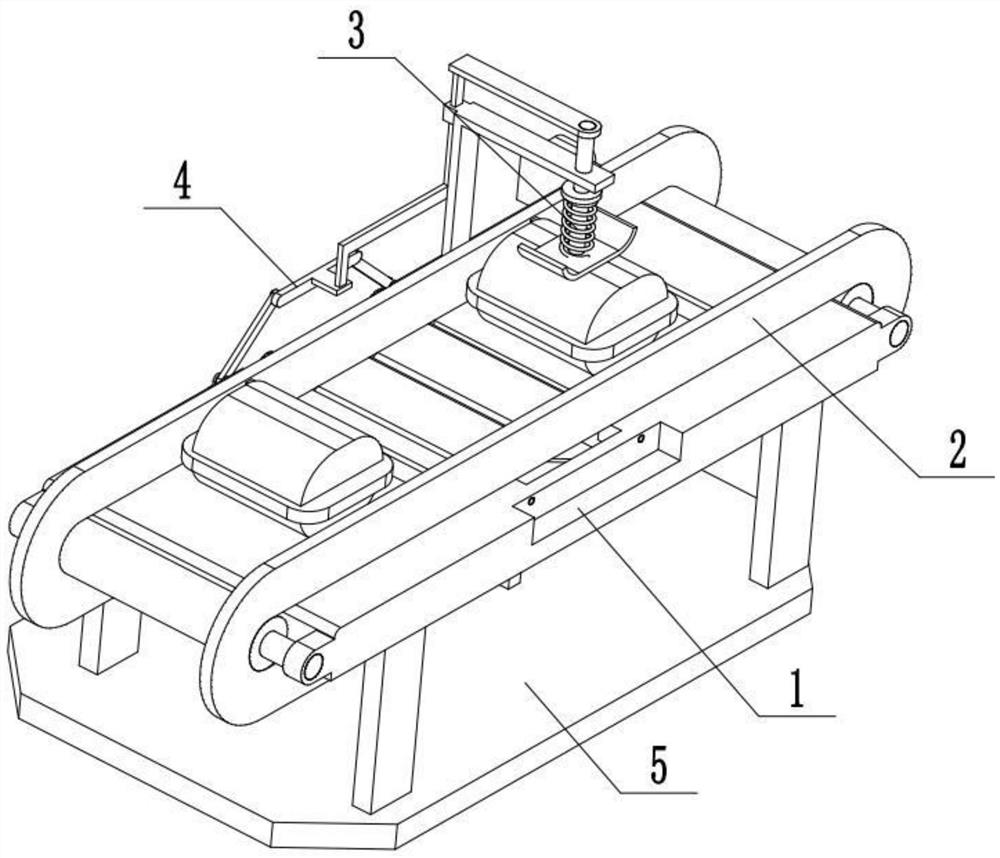

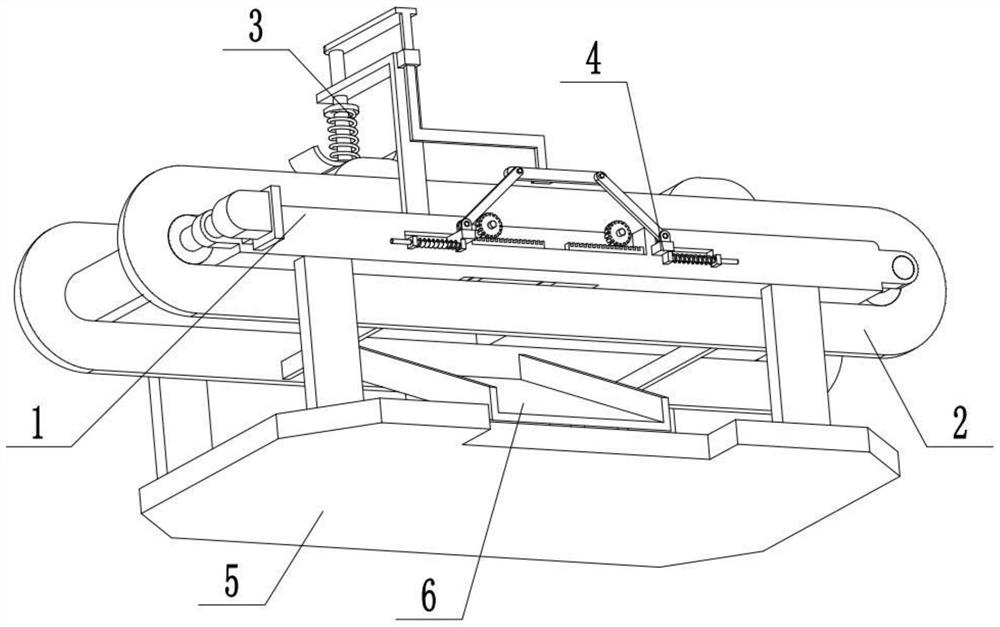

[0031] Combine below Figure 1-8Illustrating this embodiment, a processing device for laundry beads includes a horizontal frame plate 1 , a bead conveying mechanism 2 , a detection mechanism 3 , an opening and closing baffle assembly 4 , a bottom plate 5 and a material guide inclined plate 6 . The bead conveying mechanism 2 is matched and connected to the horizontal frame plate 1, the condensed bead conveying mechanism 2 is arranged on the horizontal frame plate 1, the detection mechanism 3 is connected to the opening and closing baffle assembly 4, and the opening and closing baffle assembly 4 is matched and connected to the horizontal frame plate. In the middle of 1, the horizontal frame plate 1 is arranged on the bottom plate 5, and the bottom plate 5 is provided with a material guide inclined plate 6, and the material guide inclined plate 6 is located at the lower end of the opening and closing baffle assembly 4, and the detection mechanism 3 is used to detect unqualified co...

specific Embodiment approach 2

[0032] Combine below Figure 1-8 Illustrating this embodiment, the cross frame plate 1 is provided with a condensate discharge groove 1-1, a side groove 1-2, a rack chute 1-3 and a side slide groove 1-4; There is a condensate discharge groove 1-1, the front and rear ends of the condensate discharge groove 1-1 are respectively provided with a side groove 1-2, and the two ends of the two side grooves 1-2 are respectively provided with a rack chute 1 -3, the outer ends of the two rack chute 1-3 are respectively provided with a side chute 1-4, the side chute 1-2, the rack chute 1-3 and the side chute 1-4 are all connected ; The opening and closing baffle assembly 4 is connected with the middle of the horizontal frame plate 1, and the bead conveying mechanism 2 is connected with the two ends of the horizontal frame plate 1. Under the push of the bead conveying mechanism 2, the laundry beads are pushed and slid to the right on the horizontal frame plate 1, and the unqualified laund...

specific Embodiment approach 3

[0033] Combine below Figure 1-8 Illustrating this embodiment, the condensate conveying mechanism 2 includes a motor 2-1, a first rotating shaft 2-2, a second rotating shaft 2-3, a roller 2-4, a conveyor belt 2-5 and a partition push rod 2- 6; the output shaft of the motor 2-1 is connected to the first rotating shaft 2-2 through a coupling, the first rotating shaft 2-2 and the second rotating shaft 2-3 are respectively connected to the two ends of the horizontal frame plate 1 in rotation, and the first rotating shaft 2 A roller 2-4 is fixedly connected to the -2 and the second rotating shaft 2-3 respectively. The two rollers 2-4 are connected by transmission through two conveyor belts 2-5, and there are evenly arranged between the two conveyor belts 2-5. A plurality of partition push rods 2-6, the motor 2-1 is fixedly connected to the horizontal frame plate 1 through the motor frame. Laundry beads are located between two adjacent partition push rods 2-6; motor 2-1 starts to d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com