Polymer foam particles with skin and dilatancy and preparation method thereof

A technology of polymer particles and foam particles, applied in the direction of coating, can solve problems such as single performance, and achieve the effect of low density, good energy absorption capacity, and good energy dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0600] In the preparation process of the skin-expandable polymer foam particles, those skilled in the art can choose a suitable foaming method to prepare the polymer foam particles according to the actual preparation situation and the properties of the target polymer.

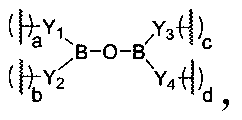

[0601] The present invention provides a preferred and suitable method for preparing skinned dilatant polymer foam particles, which is characterized in that it uses intrinsic dilatant polymer and / or non-dilatant polymer, foaming agent and Optional dispersible dilatant dispersion, optional other additives, optional fillers as raw materials, prepared by the following methods:

[0602] Premix the intrinsic dilatant polymer / non-dilatant polymer, optional other additives, and optional fillers, and use extrusion equipment to extrude and pelletize the resulting polymer particles and foaming agent , Optional dispersible dilatant dispersion liquid and optional suspension are added to a closed reactor to be immersed by heating...

Embodiment 1

[0669] Weigh 20g of hydroxyl-terminated polyethylene oxide in a dry and clean flask, heat it to 110°C to remove water for 1h, then add 0.2g of polyurethane catalyst A-1 and 6.0g of toluene diisocyanate, stir to react, and pour into a suitable mold Keep the mold temperature at 56°C, open the mold after 7 minutes to obtain a polyurethane sample, cut it into polyurethane particles of appropriate size, and then add it to the extruder for extrusion and drawing. The extrusion temperature is 150-170°C. The silk sample is printed with a 3D printer, and the melting temperature of the equipment is controlled to 150°C. After maintaining at this temperature for 15 minutes, it will be ejected from the printer nozzle and printed into foam particles with a pneumatic dilatant structure and an outer skin structure. After the printing is completed , Placed in a constant temperature oven for a period of time, take out the naturally cooled expandable polymer foam particles with skin, the obtained p...

Embodiment 2

[0671]

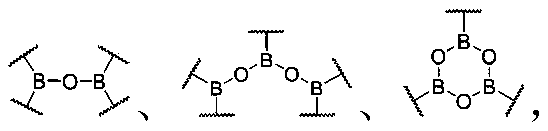

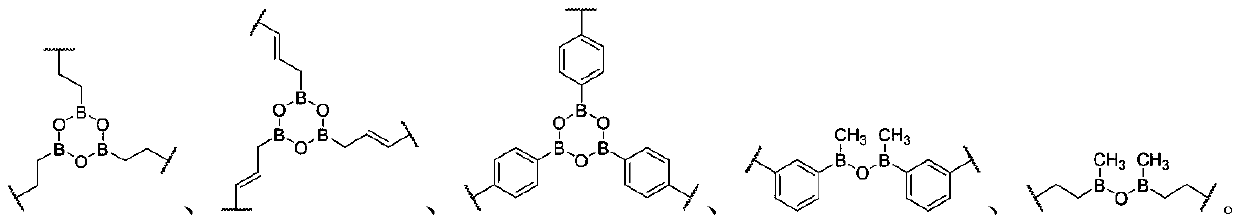

[0672] Using triethylamine as a catalyst, equimolar amounts of [(1E)-6-hydroxy-1-hexen-1-yl]boronic acid and 3-(2-hydroxyethoxy)propane-1,2-diol The condensation reaction is carried out at 50° C. to obtain the organic borate compound (a).

[0673] Mix 2 molar equivalents of polyethylene glycol 500 and 2 molar equivalents of organoborate compound (a) in toluene solvent, add a small amount of triethylamine, stir and heat to 80°C, slowly add 4 molar equivalents of diphenyl Methyl methane diisocyanate, and then continue to react for 2 hours, then add methanol for capping, remove the solvent after the reaction is complete, and prepare dilatant polyurethane elastomer after cooling, which is broken into granules.

[0674] Combine 90 parts by weight of dilatable polyurethane elastomer particles, 10 parts by weight of expandable microspheres (Expancel microspheres from Akzo Nobel), 0.08 parts by weight of zinc borate, and 8 parts by weight of sorbitan monolaurate. Ester, 0.05 part...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com