Preparation method and application of nano-selenium

A technology of nano-selenium and sodium selenite, applied in the field of nano-selenium, can solve the problems of increased free radical content and harmful protein, and achieve the effects of good crystallinity, short reaction time, good water solubility and biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

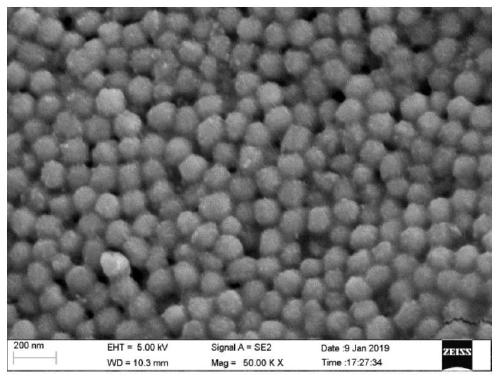

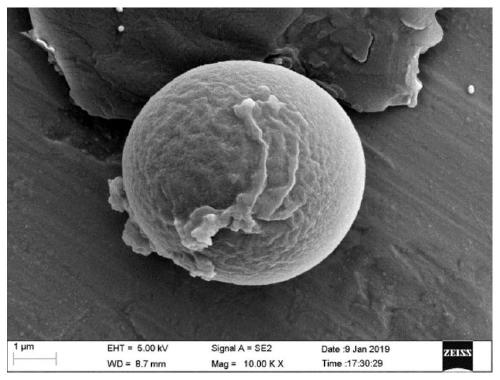

[0029] Preparation and characterization of embodiment 1 nano-selenium

[0030] 1. Preparation of nano-selenium

[0031] 1.1 Preparation of solution

[0032] 1.1.1 0.1M sodium selenite solution

[0033] Accurately weigh 1.729g of sodium selenite, use deionized water as solvent, dissolve it in a beaker with an appropriate amount of deionized water, transfer it to a 100mL volumetric flask, and add deionized water to make it up to the mark.

[0034] 1.1.2 0.1M ascorbic acid solution

[0035] Accurately weigh 0.440 g of ascorbic acid, use deionized water as solvent, dissolve in a beaker with an appropriate amount of deionized water, transfer it to a 25mL volumetric flask, and add deionized water to make it up to the mark.

[0036] 1.1.3 0.5% polyvinyl alcohol solution

[0037] Precisely weigh 0.500g of polyvinyl alcohol, use deionized water as the solvent, dissolve it in a beaker with an appropriate amount of deionized water, transfer it to a 100mL volumetric flask, and add dei...

Embodiment 2

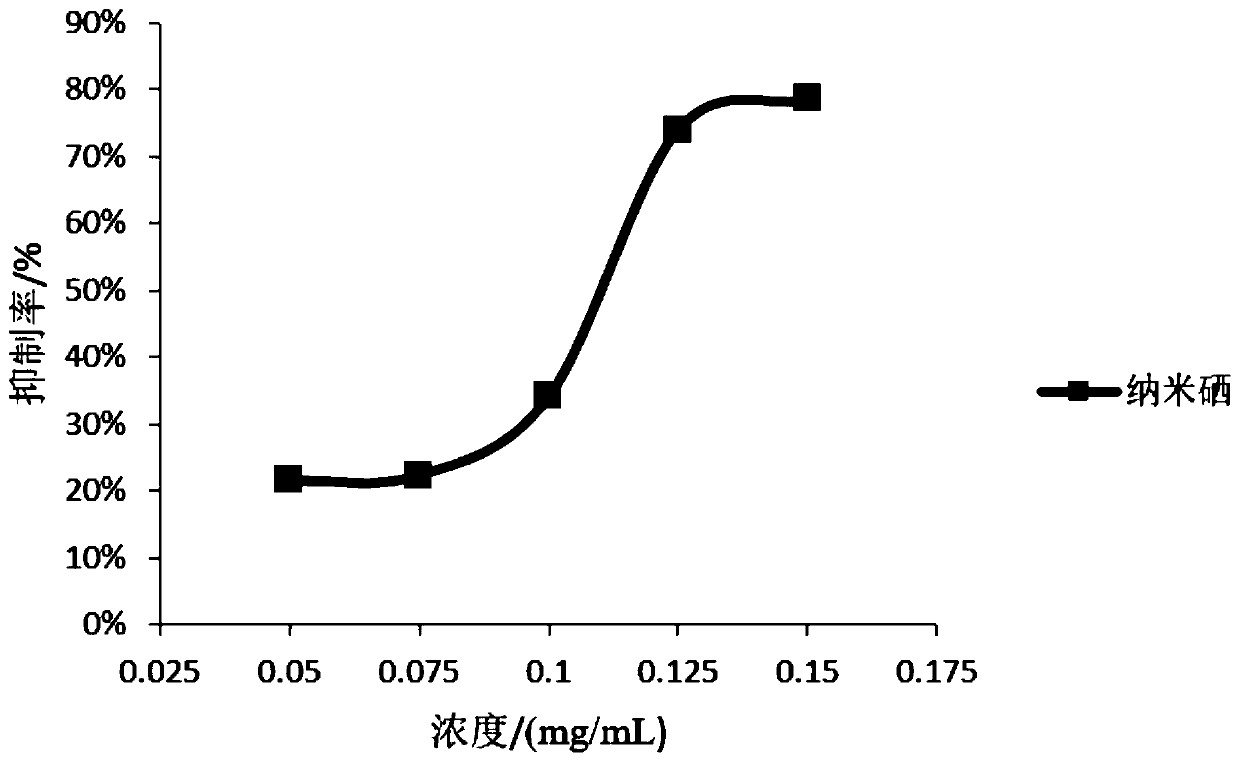

[0043] Embodiment 2 nano-selenium antioxidant test

[0044] 2.1 DPPH free radical scavenging experiment

[0045] 2.1.1 Solution preparation

[0046](1) Accurately weigh 0.0025g of 1,1-diphenyl-2-trinitrophenylhydrazine (DPPH), dissolve it with a small amount of 70% ethanol, transfer it to a 50ml brown volumetric flask, and dilute to volume with 70% ethanol to obtain 0.05mg / mLDPPH test solution, stored in the refrigerator, ready for immediate use;

[0047] (2) Take the above-mentioned nano-selenium solution and prepare solutions with concentrations of 0.5, 1.0, 1.5, 2.0 and 2.5 mg / mL.

[0048] 2.1.2 Determination of clearance rate

[0049] Accurately draw 5.00mL of sample solution, add 5.00mL of DPPH solution (0.05mg / mL), shake fully, and stand in the dark for 30min. Measure the absorbance value A of the test solution at 517nm i . After fully mixing 5.00mL of sample solution with 5.00mL of solvent, the absorbance at 517nm is A j . After fully mixing 5.00mL of DPPH solut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com