Tin disulfide-black phosphorus composite material as well as preparation method and application thereof

A composite material and tin disulfide technology, applied in chemical instruments and methods, tin compounds, phosphorus compounds, etc., can solve the problems of ppb-level gas detection and high working temperature, and achieve large-scale production and application, combined stability, The effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

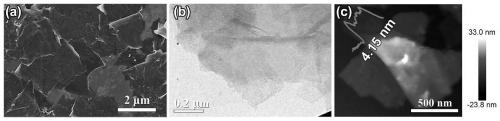

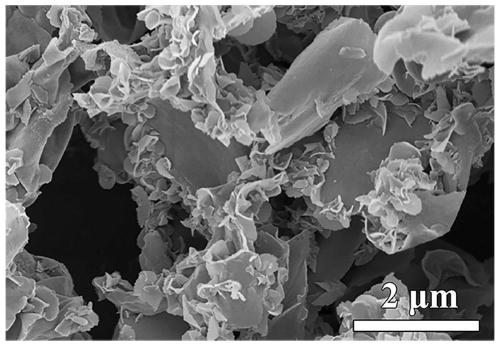

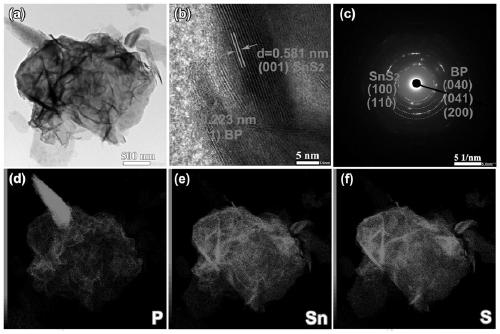

Image

Examples

Embodiment 1

[0044] 1) The present invention adopts electrochemical method to peel off and prepare black phosphorus nanosheet, concrete operation is as follows:

[0045] The platinum wire is used as the counter electrode, and the black phosphorus block material is used as the working electrode to form a two-phase working circuit. The voltage of 10V is provided through the electrochemical workstation and kept for 30 minutes; the electrolyte is dimethyl sulfoxide dissolved in tetramethylammonium tetrafluoroborate Solution, every 50mL of dimethyl sulfoxide is added with 300mg of tetramethylammonium tetrafluoroborate; the black phosphorus block expands into a sponge.

[0046] 2) Disperse the spongy black phosphorus in the cell crusher, set the time to 7min, the power to 270W, and the working time and rest time to be 5s respectively.

[0047] 3) Centrifuge the dispersed black phosphorus nanosheets at a rotational speed of 2000 rpm for 5 minutes, and then take the suspension above it to remove t...

Embodiment 2

[0062] 1) In the two-phase electrolyzer device, the platinum wire is used as the counter electrode, and the black phosphorus block material is used as the working electrode, and the voltage of 15V is provided through the electrochemical workstation and kept for 15min; the electrolyte used is dissolved tetramethyl ammonium tetrafluoroborate dimethyl sulfoxide solution, 100 mg of tetramethylammonium tetrafluoroborate was added to every 30 mL of dimethyl sulfoxide.

[0063] 2) The spongy black phosphorus obtained after electrochemical stripping was crushed in a cell crusher for 6 minutes with a power of 240W, and the working time and resting time were 4s respectively.

[0064] 3) Centrifuge the dispersed black phosphorus nanosheets at a rotation speed of 1500 rpm for 8 minutes, and then take the suspension above it.

[0065] 4) The suspension dispersed with black phosphorus nanosheets was centrifuged and washed in absolute ethanol at a rotation speed of 10000 rpm for 8 minutes, c...

Embodiment 3

[0070]1) Use the platinum wire as the positive electrode and the black phosphorus block material as the negative electrode in the two-phase electrolyzer device, use the platinum wire as the counter electrode, and the black phosphorus block material as the working electrode, provide 25V voltage through the electrochemical workstation, and keep it for 10min The block black phosphorus expands into a spongy shape, and the electrolyte used is a dimethyl sulfoxide solution containing tetramethylammonium tetrafluoroborate, and 200mg of tetramethylammonium tetrafluoroborate is added to every 40mL of dimethyl sulfoxide.

[0071] 2) Disperse the spongy black phosphorus in the cell crusher, set the time to 10min, the power to 210W, and the working time and rest time to be 3s respectively.

[0072] 3) Centrifuge the dispersed black phosphorus nanosheets at a rotation speed of 1800 rpm for 6 minutes, and then take the suspension above it.

[0073] 4) The ultrasonicated black phosphorus nan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| band gap | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com