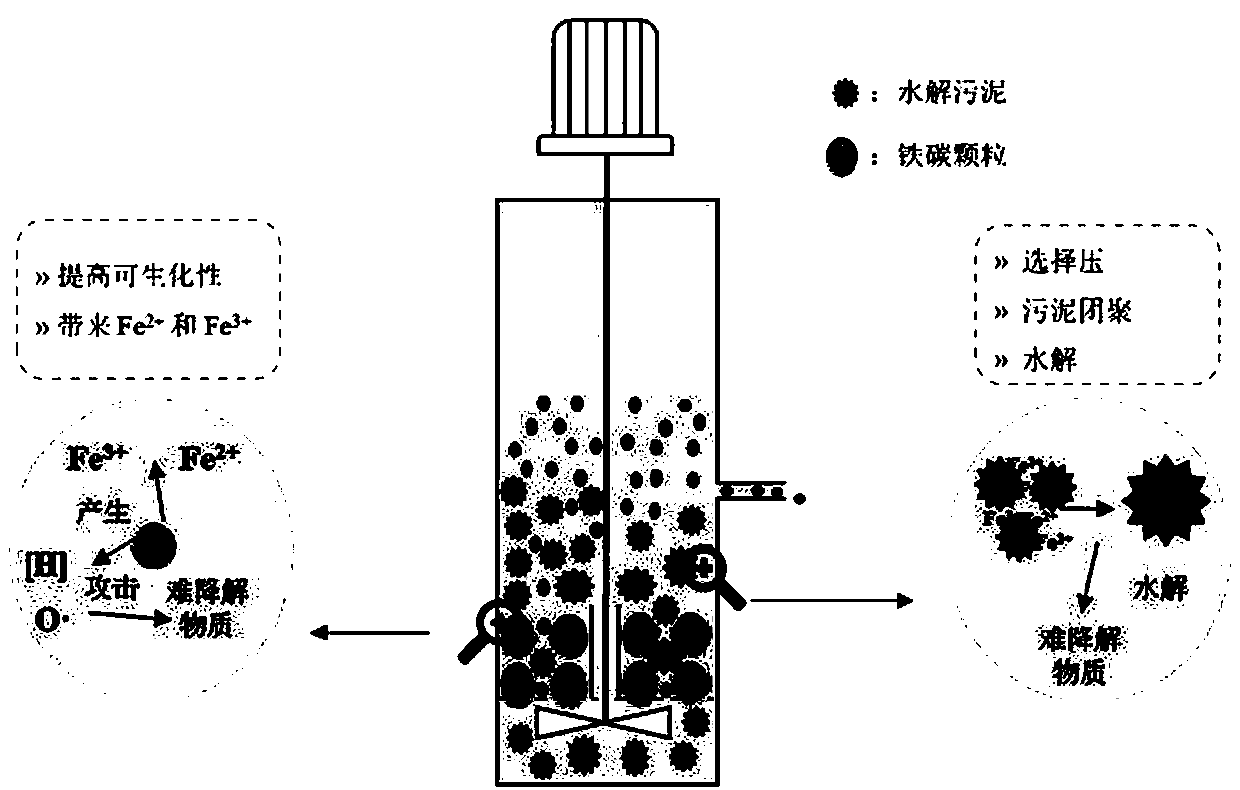

Technology for pretreating degradation-resistant sewage by coupling iron carbon and hydrolyzed granular sludge

A technology of granular sludge and pretreatment, applied in water/sludge/sewage treatment, biological water/sewage treatment, special compound water treatment, etc. It can solve the problem of large iron dissolution and achieve the effect of promoting the formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A technology that uses iron-carbon and hydrolyzed granular sludge coupling to treat refractory wastewater. Two sets of sequencing batch hydrolysis reactors with the same operating conditions are set up, and the effective volume is 3L. Add a fixed layer at the middle and lower part of the water level of one of the hydrolysis tanks, add 400g of iron carbon on the fixed layer, choose the refractory wastewater as aquaculture wastewater, COD is about 700mg / L, B / C is about 0.2, NH 4 + -N concentration is about 450mg / L, TP is about 15mg / L; during the operation of the system, the pretreatment effect of the iron-carbon filler group is significantly better than that of the non-addition iron-carbon group, and the B / C average of the iron-carbon filler group is increased to 0.30, while the group without adding iron-carbon filler only increased to 0.25; and the group adding iron-carbon filler had a certain phosphorus removal effect, which could remove 2.2mg / L phosphorus on average; t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com