Environment-friendly building board and preparation method thereof

A technology for building panels and environmental protection, which is applied in the field of environmentally friendly building panels and its preparation, can solve the problems of moldy panels, composite panels without antibacterial properties, and germs endangering the health of installers, etc., achieving good environmental protection, simple and easy preparation methods, Excellent effect of weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

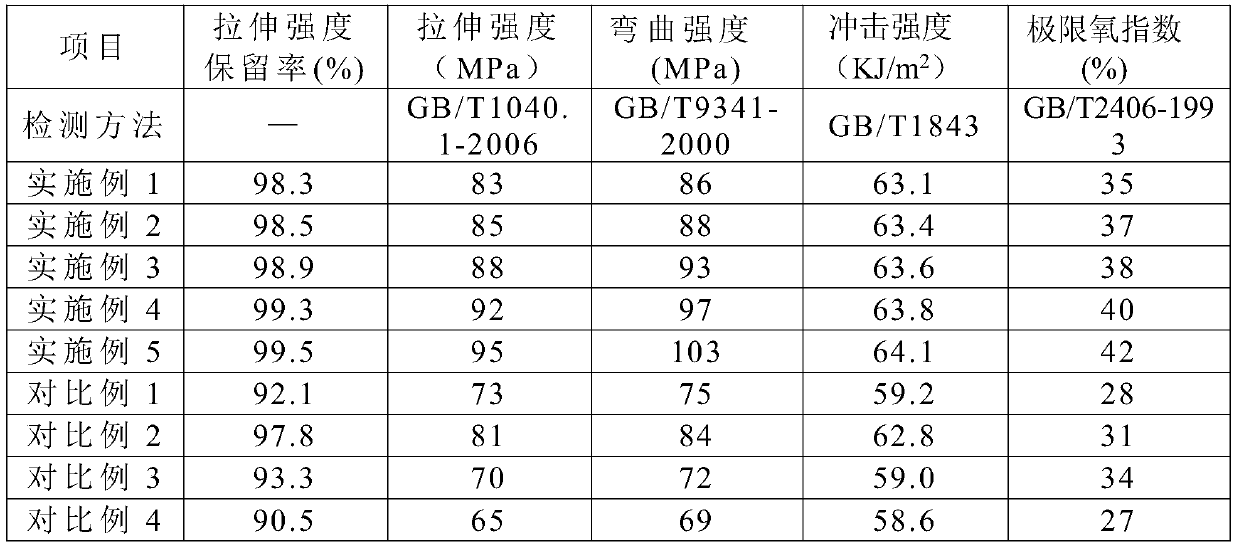

Examples

Embodiment 1

[0033] An environmentally friendly building board, characterized in that it is made of the following raw materials in parts by weight: 20 parts of waste thermoplastic ABS plastics, modified 9-fluorenone-2,7-dicarboxylic acid / 3,6-diamino 60 parts of carbazole condensation polymer, 10 parts of 1,3-divinyltetraethoxydisilane modified glass fiber / mullite fiber composite material, 1 part of azobisisobutyronitrile, 2 parts of allylbenzothiazole, 5 parts of epoxidized soybean oil.

[0034] The preparation method of the 1,3-divinyltetraethoxydisilane modified glass fiber / mullite fiber composite material comprises the following steps: dispersing 300g of glass fiber and 100g of mullite fiber in 1500g of ethanol, Then add 50g of 1,3-divinyltetraethoxydisilane, stir and react at 30°C for 6 hours, and then remove the solvent by rotary evaporation to obtain 1,3-divinyltetraethoxydisilane modified glass fiber / mullite fiber composite.

[0035] The preparation method of the modified 9-fluore...

Embodiment 2

[0040] An environmentally friendly building board, characterized in that it is made of the following raw materials in parts by weight: 23 parts of waste thermoplastic ABS plastics, modified 9-fluorenone-2,7-dicarboxylic acid / 3,6-diamino 65 parts of carbazole condensation polymer, 11 parts of 1,3-divinyltetraethoxydisilane modified glass fiber / mullite fiber composite material, 1.5 parts of azobisisoheptanonitrile, 2.5 parts of allylbenzothiazole, 6 parts of epoxy butyl furfurate.

[0041] The preparation method of the 1,3-divinyltetraethoxydisilane modified glass fiber / mullite fiber composite material comprises the following steps: dispersing 300g of glass fiber and 100g of mullite fiber in 1650g of tetrahydrofuran, Then add 50g of 1,3-divinyltetraethoxydisilane, stir and react at 35°C for 6.5 hours, and then remove the solvent by rotary evaporation to obtain 1,3-divinyltetraethoxydisilane modified glass fiber / mullite fiber composite.

[0042] The preparation method of the mo...

Embodiment 3

[0047] An environmentally friendly building board, characterized in that it is made of the following raw materials in parts by weight: 25 parts of waste thermoplastic ABS plastics, modified 9-fluorenone-2,7-dicarboxylic acid / 3,6-diamino 70 parts of carbazole condensation polymer, 13 parts of 1,3-divinyltetraethoxydisilane modified glass fiber / mullite fiber composite material, 2 parts of azobisisobutyronitrile, 3 parts of allylbenzothiazole, 8 parts of methyl epoxy acetyl linoleate.

[0048] The preparation method of the 1,3-divinyltetraethoxydisilane modified glass fiber / mullite fiber composite material comprises the following steps: dispersing 300g of glass fiber and 100g of mullite fiber in 1750g of acetone, Then add 50g of 1,3-divinyltetraethoxydisilane, stir and react at 40°C for 7 hours, and then remove the solvent by rotary evaporation to obtain 1,3-divinyltetraethoxydisilane modified glass fiber / mullite fiber composite.

[0049] The preparation method of the modified ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com