Surface-emitting semiconductor laser chip and preparation method thereof

A surface-emitting, semiconductor technology, applied in the field of surface-emitting semiconductor laser chips and their preparation, to achieve the effects of easy production, improved beam quality, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

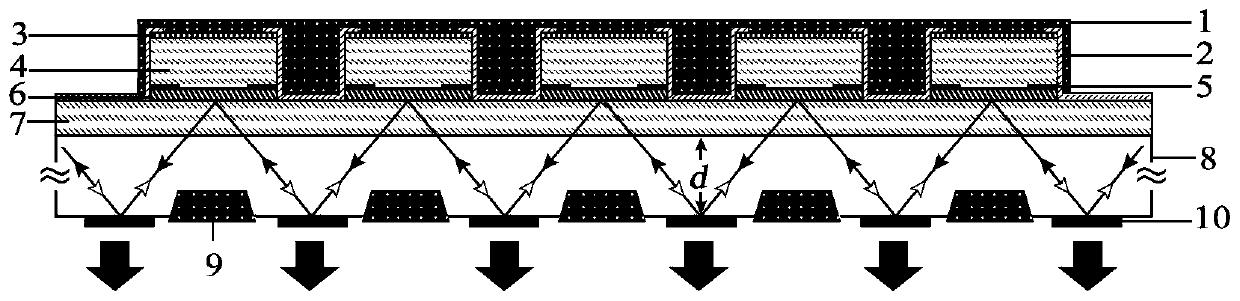

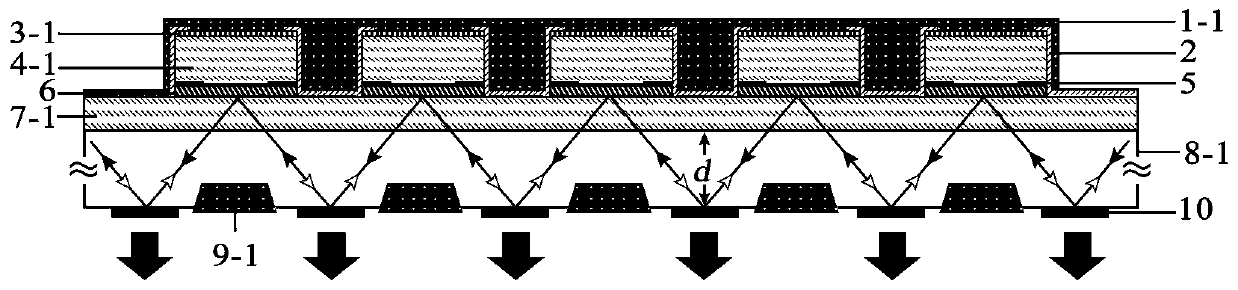

[0065] The invention discloses a surface-emitting semiconductor laser chip and a preparation method thereof. The semiconductor laser chip is a surface-emitting two-dimensional array light source chip which emits laser light from the bottom of a substrate layer. The surface emitting two-dimensional array light source of this embodiment consists of such as figure 2 and 3 The surface emitting light sources 11 shown are arranged in a quadrangular matrix. Such as Picture 1-1 As shown, the surface-emitting semiconductor laser chip with high beam quality in this embodiment includes: P-type electrode 1-1 (first electrode), passivation layer 2, P-type ohmic contact layer 3-1, P-type rear mirror 4-1, Oxidation optical confinement layer 5, active layer 6, N-type front mirror 7-1, N-type substrate layer 8-1, N-type electrode 9-1 (second electrode), semi-reflective and semi-transparent film 10; chip from bottom to bottom N-type substrate layer 8-1, N-type front mirror 7-1, active laye...

Embodiment 2

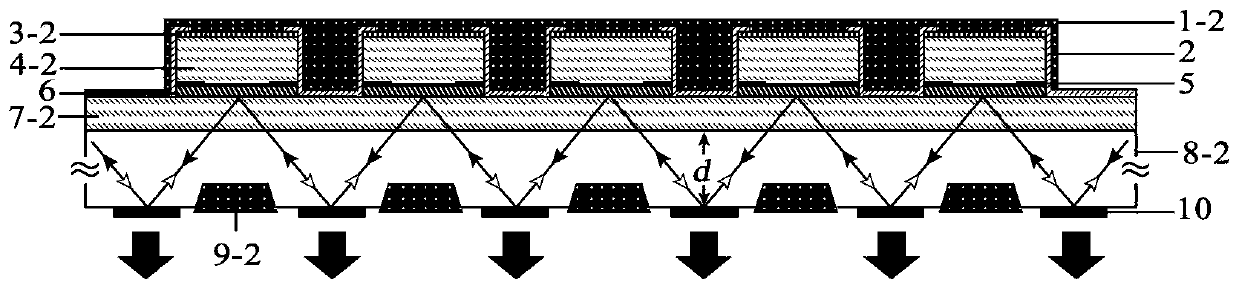

[0074] The invention discloses a surface-emitting semiconductor laser chip and a preparation method thereof. The semiconductor laser chip is a surface-emitting two-dimensional array light source chip which emits laser light from the bottom of a substrate layer. The surface emitting two-dimensional array light source of this embodiment consists of such as figure 2 and 3 The surface emitting light sources 11 shown are arranged in a quadrangular matrix. Such as Figure 1-2 As shown, the surface-emitting semiconductor laser chip with high beam quality in this embodiment includes: N-type electrode 1-2 (first electrode), passivation layer 2, N-type ohmic contact layer 3-2, N-type rear mirror 4-2, Oxidation optical confinement layer 5, active layer 6, P-type front mirror 7-2, P-type substrate layer 8-2, P-type circular electrode 9-2 (second electrode), semi-reflective and semi-transparent film 10; the chip consists of From bottom to top, there are P-type substrate layer 8-2, P-ty...

Embodiment 3

[0082] The invention discloses a surface-emitting semiconductor laser chip and a preparation method thereof. The semiconductor laser chip is a surface-emitting two-dimensional array light source chip which emits laser light from the bottom of a substrate layer. The surface emitting two-dimensional array light source of this embodiment consists of such as Figure 4 and 5 The surface emitting light sources 11 shown are arranged in a hexagonal matrix. Such as Picture 1-1 As shown, the surface-emitting semiconductor laser chip with high beam quality in this embodiment includes: P-type electrode 1-1 (first electrode), passivation layer 2, P-type ohmic contact layer 3-1, P-type rear mirror 4-1, Oxidation optical confinement layer 5, active layer 6, N-type front mirror 7-1, N-type substrate layer 8-1, N-type electrode 9-1 (second electrode), semi-reflective and semi-transparent film 10; chip from bottom to bottom N-type substrate layer 8-1, N-type front mirror 7-1, active layer 6...

PUM

| Property | Measurement | Unit |

|---|---|---|

| reflectance | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com