A kind of tissue sealant powder, its preparation process and tissue sealant

A sealing agent and powder technology, applied in the field of biodegradable polymer materials, can solve the problems of inconsistent operation of the push rod, easy formation of thrombus, and blockage of the front end of the applicator, so as to improve the instantaneous liquid absorption ability, avoid related complications, The effect of preventing postoperative adhesions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

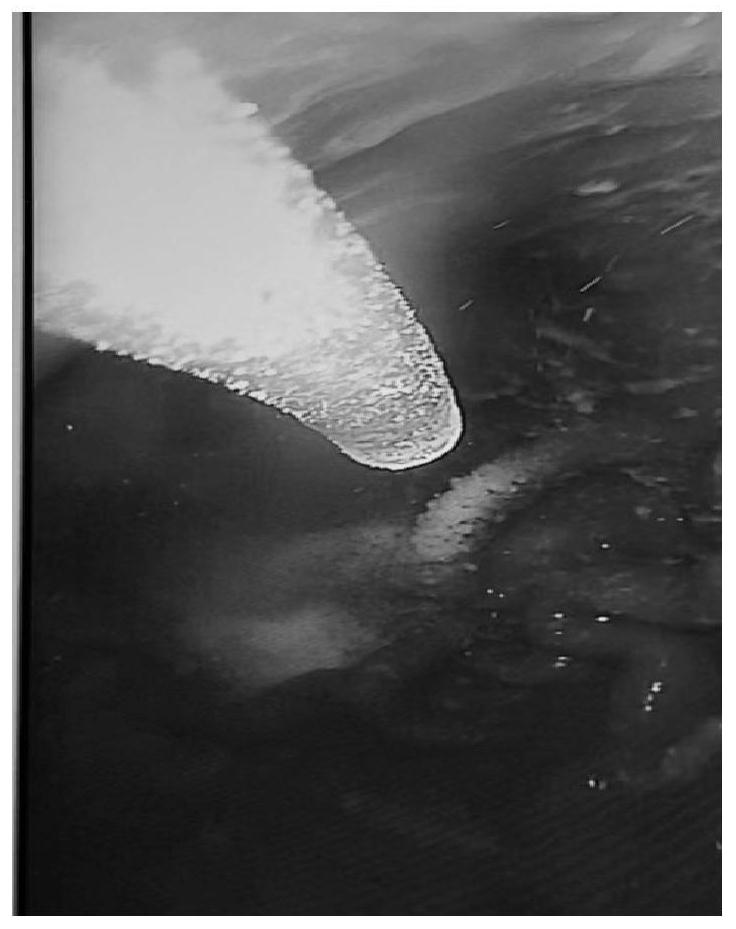

Image

Examples

Embodiment 1

[0045] The physical melting method fully mixes PEG-SS (4, 10000Da) and 4 times the quality of PEG-SS super absorbent carboxymethyl starch sodium powder, and through granulation and other processes to obtain tissue sealant powder or hemostatic material, which is applied to animals with severe For bleeding wounds, press for 25 seconds, solidify excess powder with physiological diluent, or rinse with a large amount of physiological diluent to stop bleeding. Physiological diluent is phosphate buffer (pH=7.4);

[0046] The preparation method of phosphate buffer solution with pH=7.4: Weigh 4.005g of sodium chloride, 0.1g of potassium chloride, 1.7907g of disodium hydrogen phosphate dodecahydrate, and 0.135g of potassium dihydrogen phosphate, and place them in a 500mL volumetric flask in turn , and then dissolved to obtain a PBS buffer solution with pH=7.4;

[0047] Tissue sealant powder (powder A + powder B): physiological diluent = 1:3.

Embodiment 2

[0049] The physical melting method fully mixes PEG-SC (2,5000Da) and 4 times the quality of PEG-SC super absorbent carboxymethyl starch sodium powder, and obtains tissue sealant powder through granulation and other processes, which is applied to severe bleeding wounds of animals. Press for 30 seconds to stop bleeding.

Embodiment 3

[0051] PEG-SPA (4, 10000Da) and 6 times the quality of PEG-SPA high water carboxymethyl starch sodium powder are fully mixed by physical melting method, and through granulation and other processes to obtain tissue sealant powder or hemostatic material, which is applied to animals with severe For bleeding wounds, press for 25 seconds, solidify excess powder with physiological diluent, or rinse with a large amount of physiological diluent to stop bleeding. Physiological diluent is phosphate buffer (pH=7.4); tissue sealant powder (powder A+powder B): physiological diluent=1:3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com