A kind of preparation method of mineralized flat silk sewage treatment membrane

A technology of sewage treatment and flat wire, which is applied in the direction of water/sewage treatment, adsorption water/sewage treatment, water/sludge/sewage treatment, etc. It can solve the problems of limiting the application of nano-hydroxyapatite materials and lack of adsorption materials. Achieve excellent heavy metal and organic solvent adsorption performance, simple preparation process, and short production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] This embodiment includes the following steps:

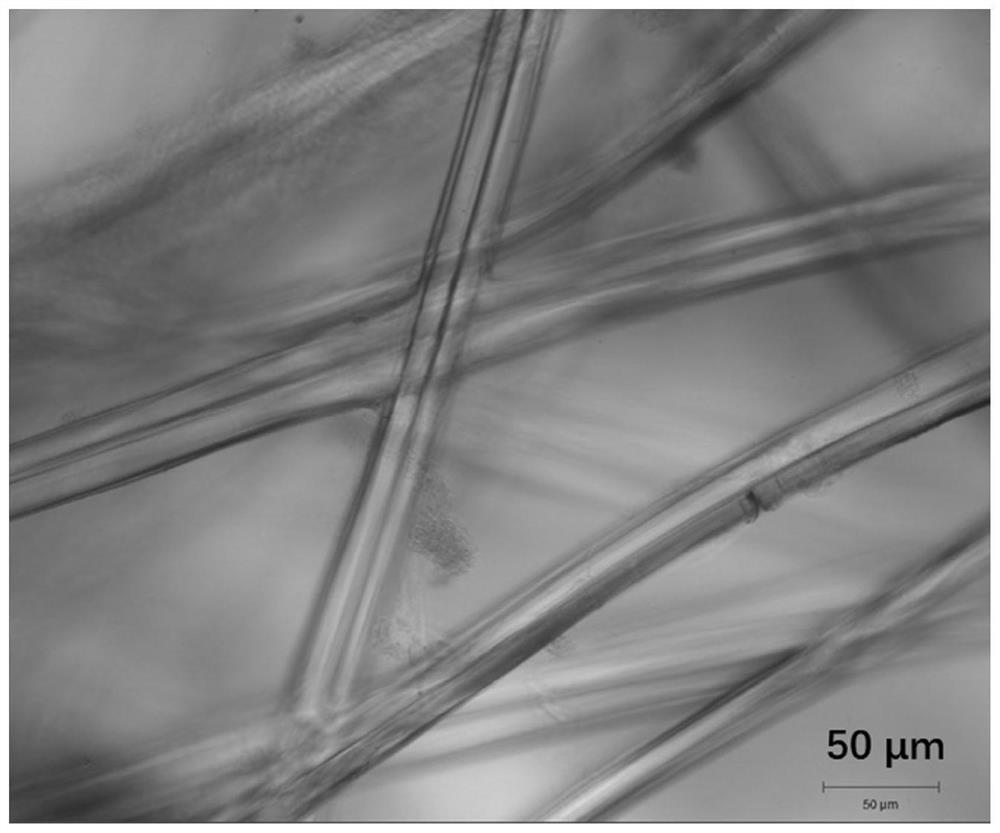

[0033] (1) The east silkworm in the spitting stage is spit in the plane object, obtain a flat wire, the micro-morphology is the micrometer fiber structure (such as figure 1 Indicated by it);

[0034] (2) Fix the flat wire in step (1), cleaner, and maintains 30 min in deionized water at 40 ° C, and delatizing;

[0035] (3) Soak the degumming plate in step (2) in a 2% urea solution, so that the crystal structure in the plate filament was softened; then soaked with 80% ethanol solution and washed several times, so that in the plate Silk protein curing, obtains the post-treated flat wire;

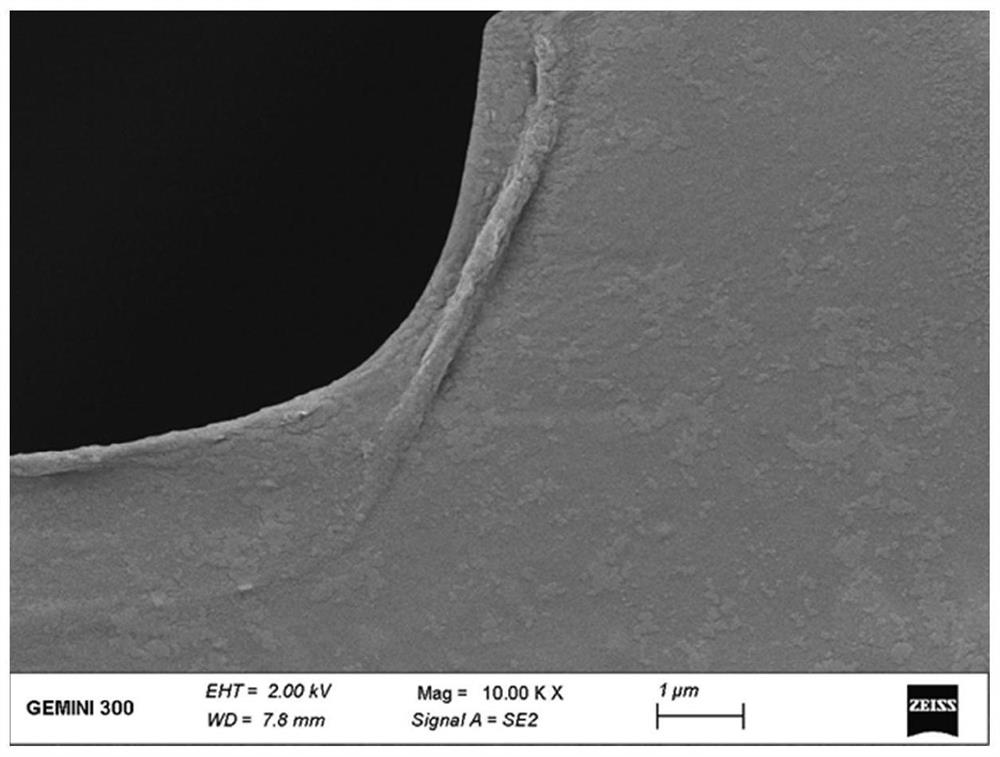

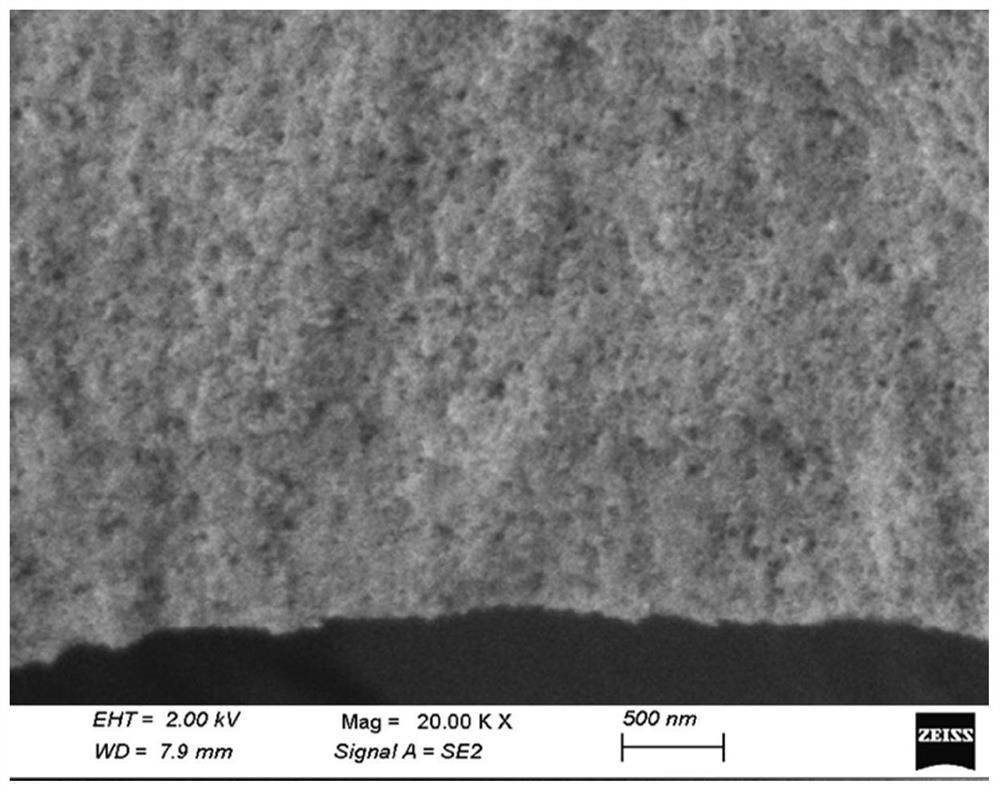

[0036] (4) The flat wire material processed in step (3) is added to the mineralization liquid for bionic mineralization. The bionic mineralization steps are as follows: put CACL 2 (Final concentration 100 mm) is added to the post-treated flat wire material soaking 1 h; 60 mm NA by constant current pump 2 HPO 4 The solution was slowly added drop...

Embodiment 2

[0038] This embodiment includes the following steps:

[0039] (1) The east silkworm in the vomer is spit in the plane object to obtain a flat wire;

[0040] (2) Secure the plates in step (1) to be fixed, cleaned, and maintain 20 min, degenerate in deionized water at 60 ° C;

[0041] (3) Soak the degumming plate in step (2) with 1% urea solution and washed several times, so that silk protein in the plate is cured to obtain a post-treated flat wire;

[0042] (4) The flat wire material processed in step (3) is added to the mineralization liquid for bionic mineralization. The bionic mineralization steps are as follows: put CA (NO 3 ) 2 · 4h 2 O (final concentration 10 mm) is added to the post-treatment flat wire material soaking 1 h; the final concentration is 6mm through the constant current pump (NH) 4 ) 2 HPO 4The solution system was slowly added dropwise to the composite solution at a rate of 2 ml / min, during which the solution system remained at a constant temperature of 40 ° C...

Embodiment 3

[0045] This embodiment includes the following steps:

[0046] (1) The east silkworm in the vomer is spit in the plane object to obtain a flat wire;

[0047] (2) Secure the flat wire in step (1), cleaner, and maintains 20 min in deionized water in the water temperature of 80 ° C for delashing;

[0048] (3) Soak the degumming plate in step (2) for 20 min in a 10% urea solution such that the crystal structure in the plate filament was softened; after soaking with 80% methanol solution and washed several times, the flattening Silk protein curing, obtains the post-treated flat wire;

[0049] (4) The flat wire material processed in step (3) is added to the mineralization liquid for bionic mineralization. The bionic mineralization step is as follows: adding CaCl2 (final concentration 20 mm) to the post-treatment flat wire material soaking 1 h; 12 mm Na by constant current pump 2 HPO 4 The solution system was slowly added dropwise to the composite solution at a rate of 5 ml / min, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com